A motor stator assembly

A motor stator and component technology, which is applied in the direction of electric components, electrical components, windings, etc., can solve problems such as damage to stator components, and achieve the effects of improving insulation, increasing creepage distance, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

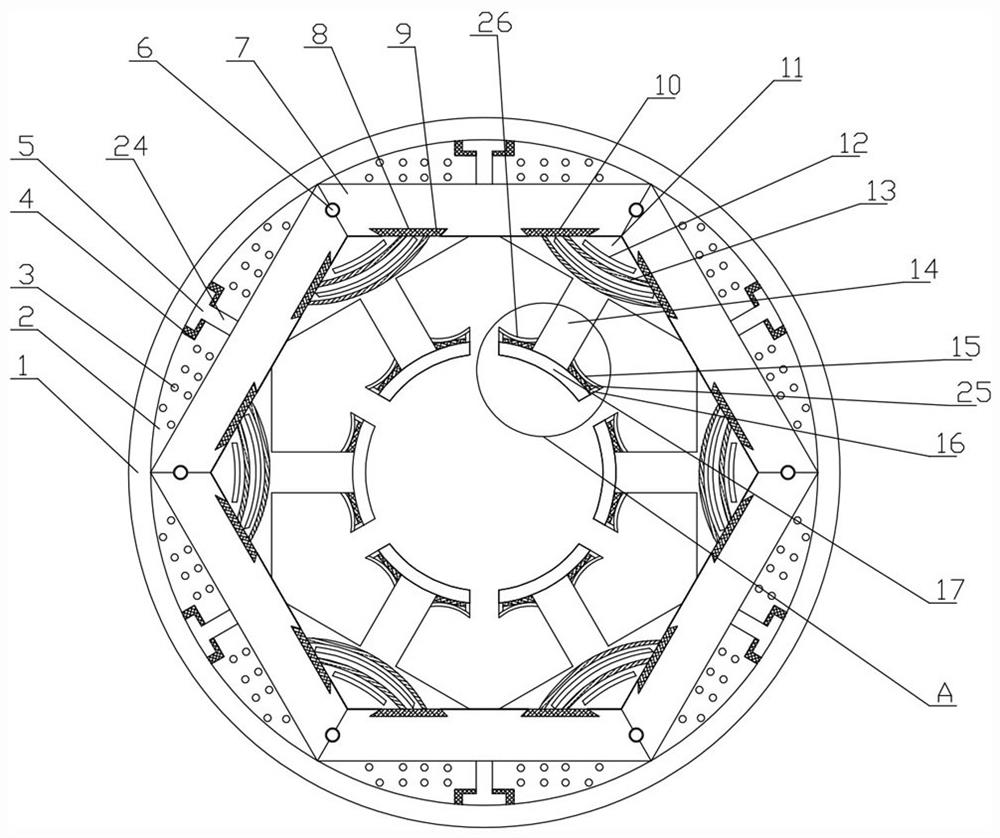

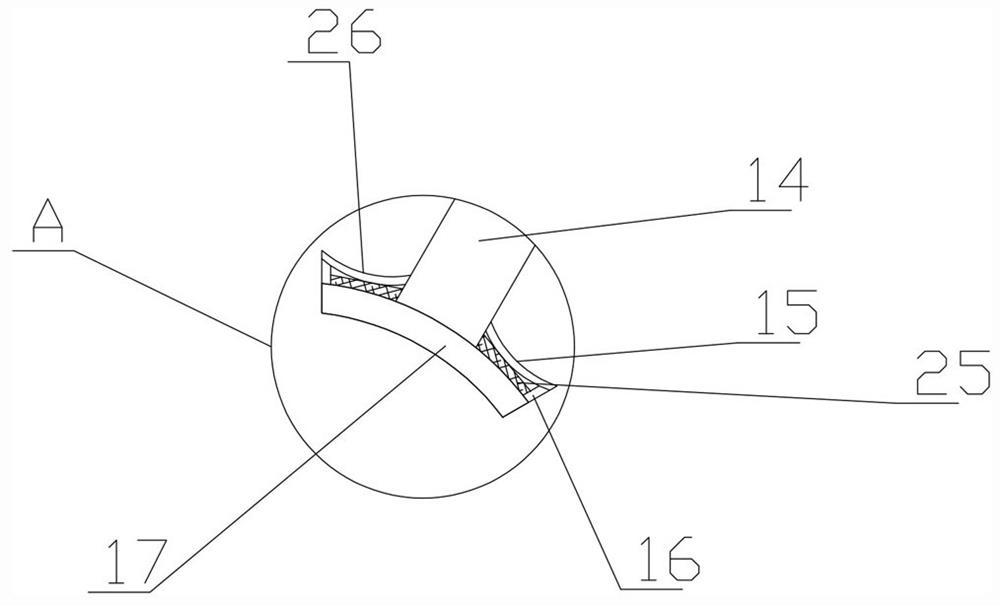

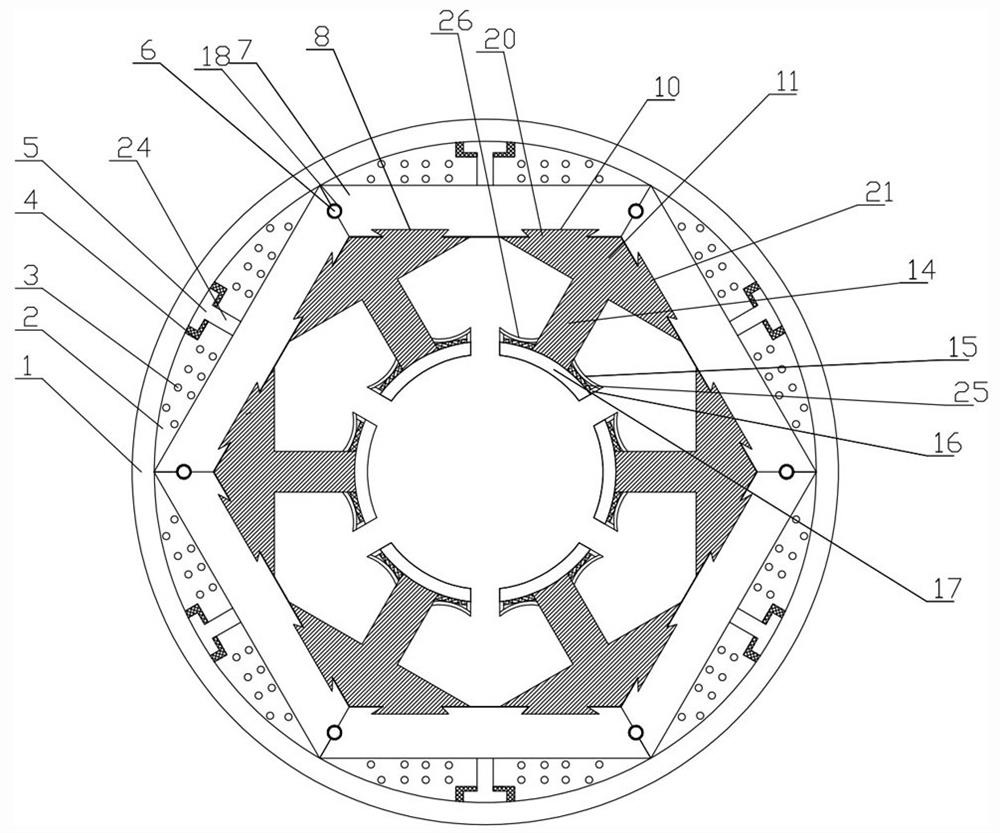

[0030] Such as Figure 1 to Figure 6 As shown, a motor stator assembly includes a housing 1 and a stator core;

[0031] The housing 1 is a cylindrical body with openings at both ends, and the inner peripheral wall of the housing 1 is provided with six supporting rods 4 in an annular array, and each of the supporting rods 4 is provided with a connecting groove. Each of the connecting grooves is a T-shaped longitudinal section with an opening facing the central axis of the housing 1. The length of the bearing rod 4 is equal to the length of the housing 1, and the front and rear ends of each connecting groove run through it. The front and rear ends of the load bar 4;

[0032] The stator core is installed inside the housing 1. The stator core includes a core yoke and a core tooth. The core yoke is an annular structure formed by six core plates connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com