Smoking oven for processing sausage products

A smoker and product technology, which is applied in the field of smoker, can solve problems such as incompleteness, low temperature and smoke concentration, and sausages that do not meet the requirements, and achieve the effect of strong practicability and promotion of smoking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

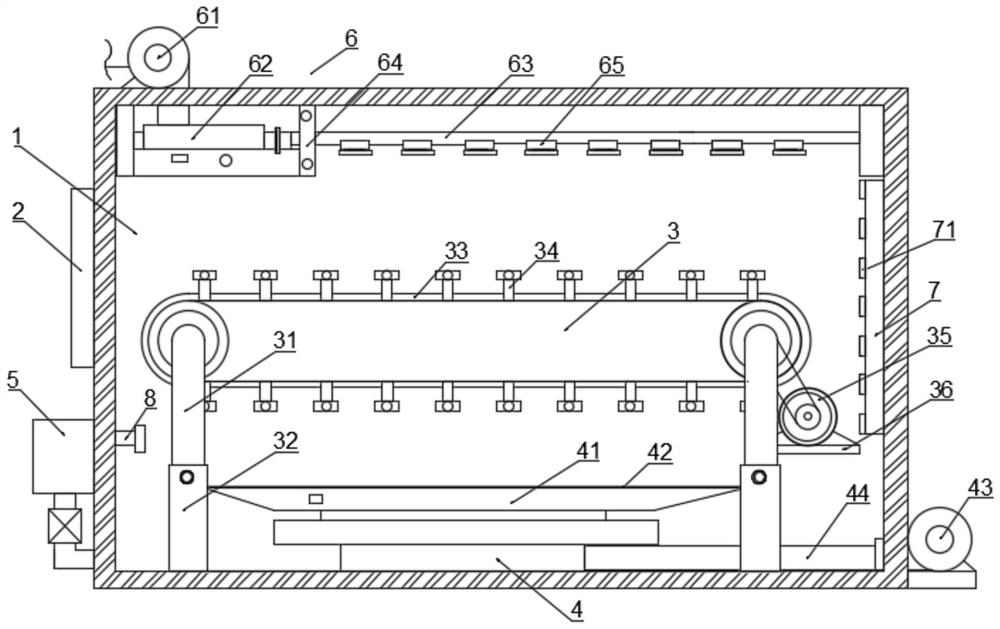

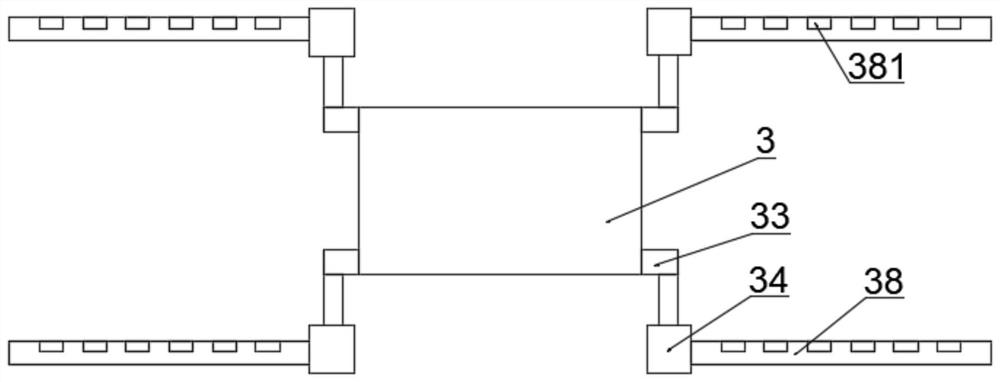

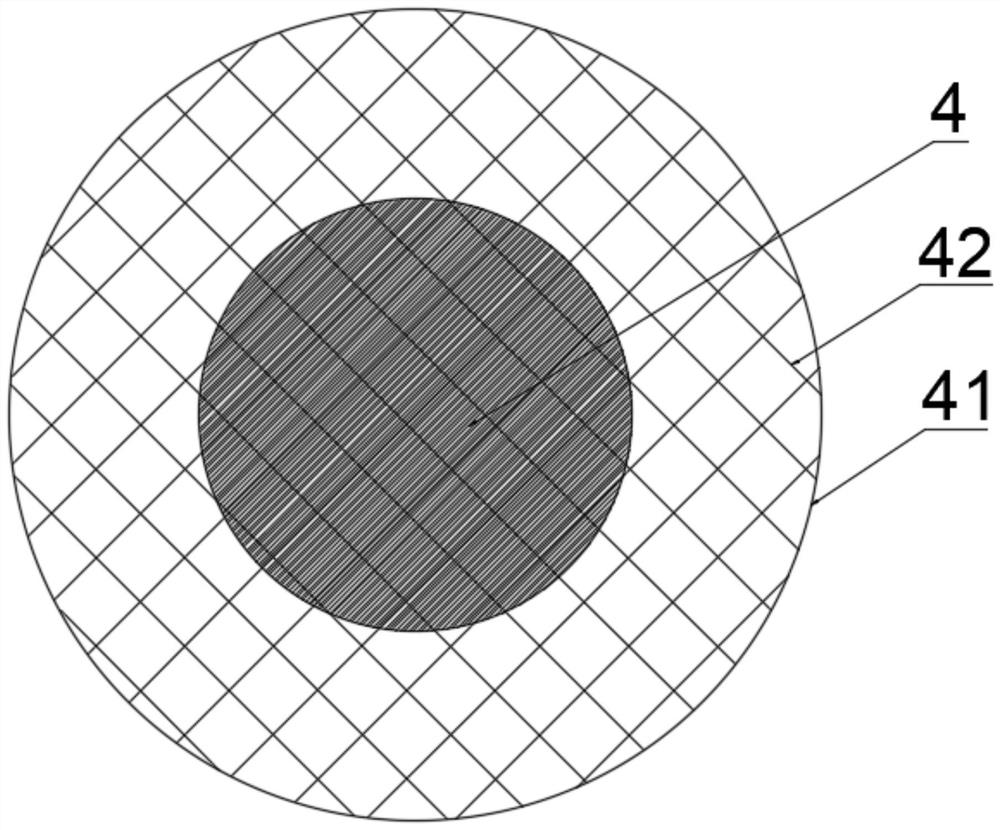

[0024] see Figure 1-4 As shown, a smoker oven for sausage products processing according to the present invention includes a smoker 1, a conveying platform 3 is provided inside the smoker 1, and the left and right sides of the conveyer 3 are provided with There is a pillar 31, and the pillar 31 is installed in the sleeve 32 in a liftable manner. The front and rear of the delivery platform 3 are provided with steps 33 facing outwards, and a transfer rod 34 is installed on the step 33. There is a plug-in block, and the center of the plug-in block is fixedly welded with a plug-in rod 38. The plug-in rod 38 is provided with a hanging interface 381 for sausage hanging at intervals. Smoke chamber 4, the top of the smoke chamber 4 is connected with a smoke outlet 41, the top of the smoke outlet 41 is covered with a filter screen 42, and the outside of the smoke chamber 1 is provided with a second blower 5 , the second air intake pipe 51 of the second air blower 5 is arranged at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com