Purging device for valve production

A technology of cleaning and blowing, which is applied to the cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc., can solve the problems of low work efficiency, poor cleaning effect, unfavorable enterprise development, etc., to improve work efficiency. , the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

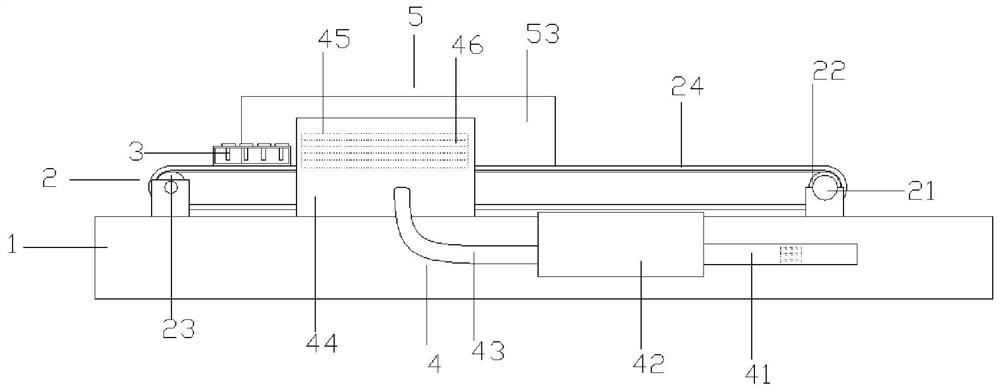

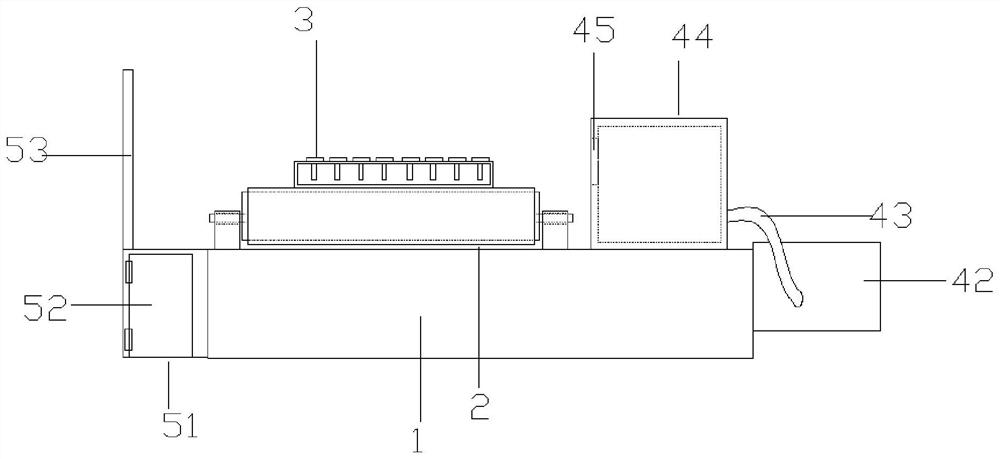

[0024] Figure 1-Figure 2 Shown is a cleaning and blowing device for valve production, the cleaning and blowing device includes a production rack 1, a transfer structure 2 placed on the production rack 1, a valve 3 placed on the transfer structure 2, placed on the production rack 1 Rack 1 and the cleaning and blowing structure 4 arranged along the direction of the conveying structure 2, the dust collecting structure 5 placed on the production rack 1 and arranged along the direction of the conveying structure 2, the cleaning and blowing structure 4 and the collecting The dust structure 5 is relatively arranged,

[0025] The output end of the cleaning and blowing structure 4 is higher than the conveying structure 2 and matches the height of the air valve 3 , and the top of the dust collecting structure 5 is higher than the cleaning and blowing structure 4 .

[0026] The transmission structure 2 includes a drive motor 21 placed on the upper end side of the production frame 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com