A cross-shaped workpiece assembly and welding device

A welding device and cross-shaped technology, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of difficult deformation control and difficult clamping of cross-shaped workpieces for welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

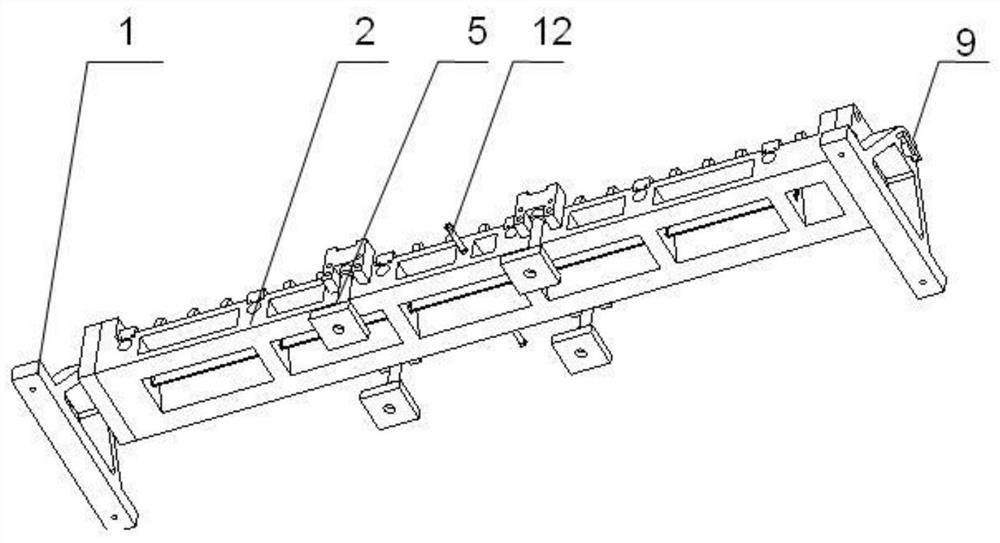

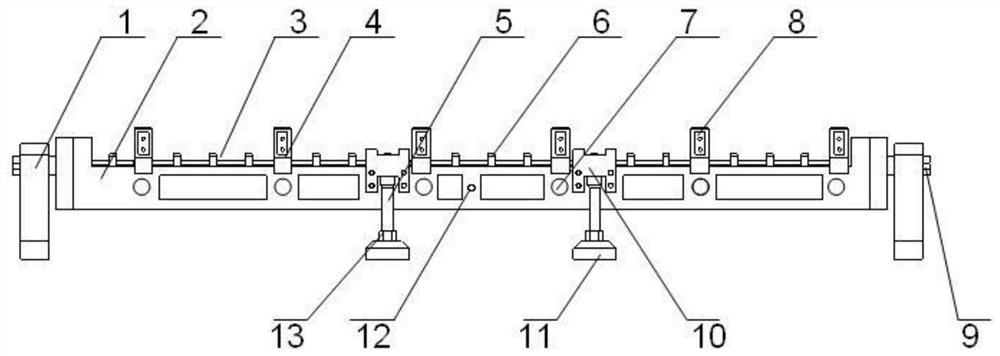

[0038] This embodiment provides a cross-shaped workpiece assembly and welding device, including a mounting base 2 and a support 1, the mounting base 2 is mounted on the support 1, the mounting base 2 is a cuboid frame structure, and the mounting base 1 is placed on the support 1 through the support 1. on the workbench or on the workshop floor.

[0039] The upper surface of the installation base 2 is provided with a through groove, the length of the through groove extends in the same direction as the length of the installation base 2, and the through groove runs through the installation base 2 along the height direction of the installation base 2; the through groove is used to install the cross-shaped workpiece to be welded , a plurality of cross-shaped workpieces to be welded can be arranged at intervals in the through groove along the length direction of the mounting base 2 .

[0040] The side surface of the mounting base 2 is provided with a plurality of threaded holes, and ...

Embodiment 2

[0045] On the basis of Embodiment 1, it is further improved, and further includes a plurality of key press bars 6 and pressing bolts 14, and the long axis direction of each key press bar 6 is in the same direction as the width direction of the through groove; the upper surface of the mounting base 2 is provided with A plurality of threaded holes, through holes are provided on the key press bar 6; after the pressing bolt 14 passes through the through hole on the key press bar 6, the thread is threaded with the threaded hole on the installation base 2, and the key press strip 6 is fixed on the installation base. 2. The upper surface; the pressing plate 3 is pressed between the lower surface of the key bead 6 and the upper surface of the mounting base 2. Further preferably, a plurality of through holes are provided on the key bead 6, and the plurality of through holes are evenly distributed along the axial direction of the key bead 6; near the side.

Embodiment 3

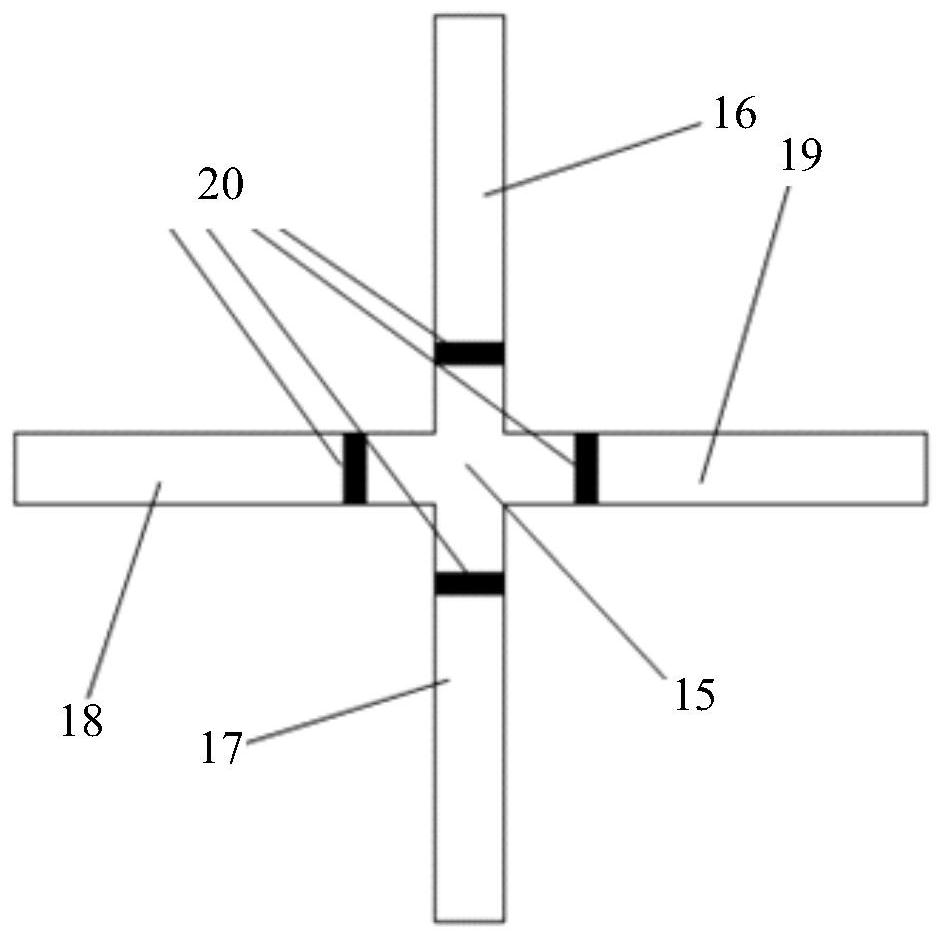

[0047] Further improvement is made on the basis of Embodiment 2. Each bridge-shaped stopper 4 is an L-shaped plate, and the free end of the vertical plate of the L-shaped plate is fixed on the upper surface of the mounting base 2, and the free end of the horizontal plate of the L-shaped plate is free. The end faces another bridge-shaped limiting member 4 in the same group, and the two L-shaped plates are symmetrically distributed in a bridge-shaped structure; the vertical plate of each L-shaped plate is also provided with a pressing member 8; the pressing member 8 is used for The upper wing plate 16 in the cruciform workpiece to be welded is pressed. The pressing member 8 is a plate-like structure, and the pressing member 8 is fixed on the vertical plate of the L-shaped plate by bolts. At this time, the pressing member 8 preferably adopts bolts. After the bolts on both sides penetrate the vertical plate of the L-shaped plate, the bolts The ends of the upper wing plate 16 abut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com