Jet printing device for degradable plastic bag production

A technology for placing plastic bags and boards, which is applied to printing, typewriters, etc. It can solve the problems of low quality of inkjet codes, smooth plastic bags, and inconvenient production, so as to improve production quality and efficiency, improve leveling efficiency, and improve inkjet codes. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

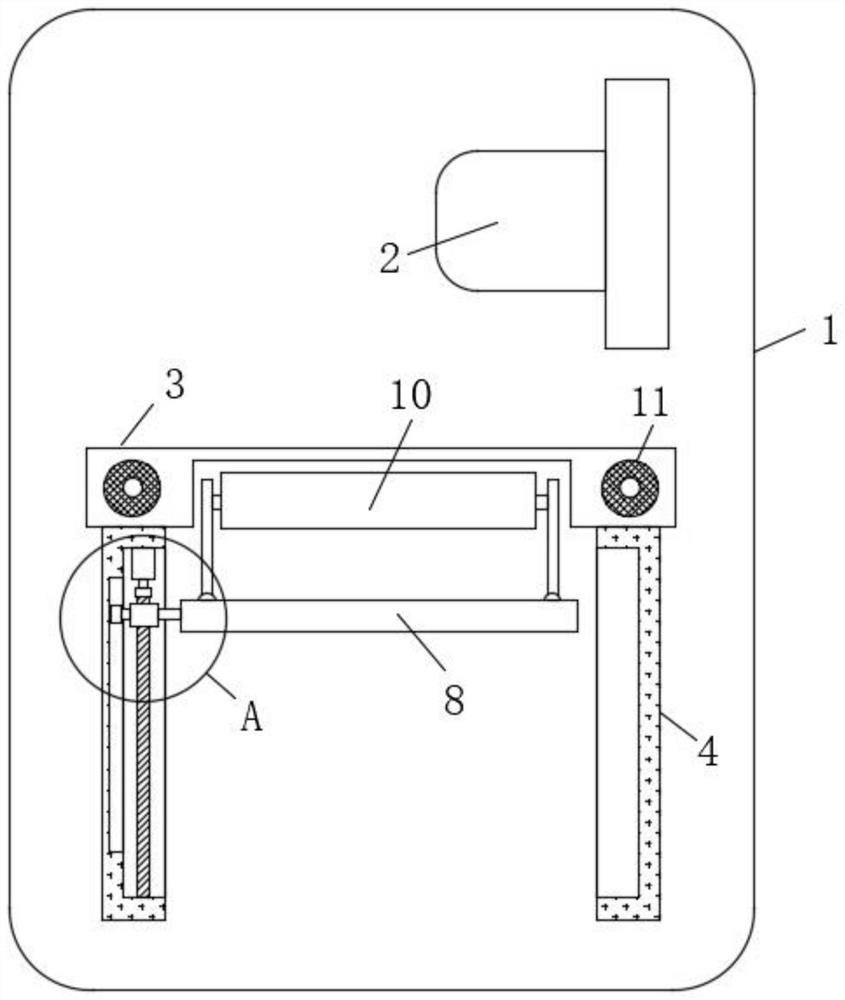

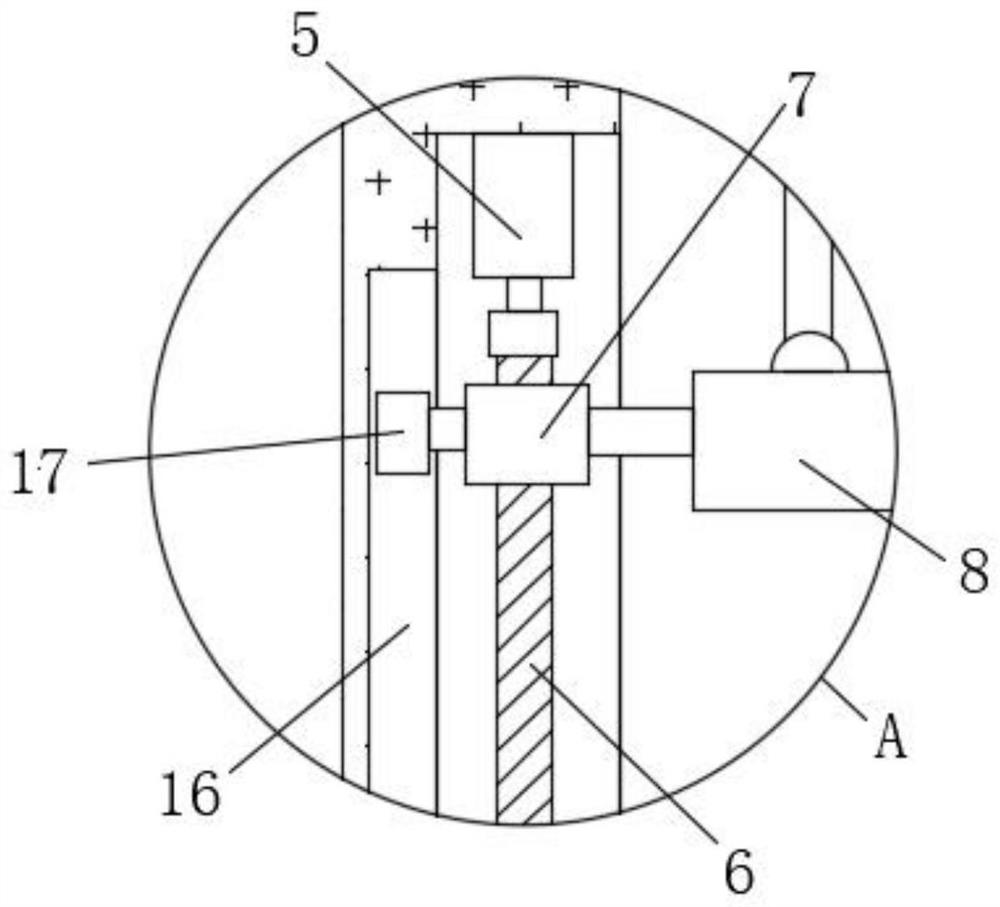

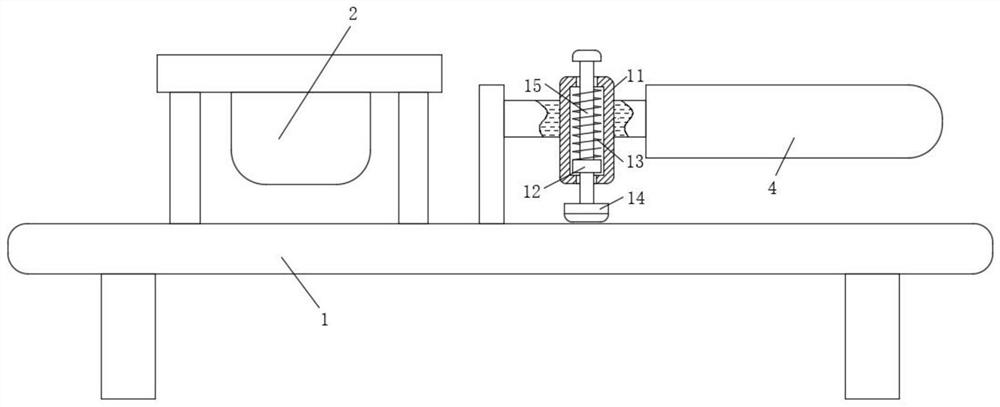

[0022] The following is attached Figure 1-3 , to further illustrate the specific implementation of a spray printing device for the production of degradable plastic bags of the present invention. A spray printing device for producing degradable plastic bags according to the present invention is not limited to the description of the following examples.

[0023] This embodiment provides a specific structure of a spray printing device for the production of degradable plastic bags, such as Figure 1-3 As shown, it includes a placement board 1, the top of the placement board 1 is fixedly connected to a symmetrically arranged support rod, the top of the support rod is fixedly connected to a fixing board, the bottom of the fixing board is fixedly connected to a jet printer 2, and the top of the placement board 1 is fixedly connected to There is a push rod, and the push rod is located on the side of the support rod;

[0024] The side of the push rod is fixedly connected with a conca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com