A rubberized asphalt concrete

A rubberized asphalt and concrete technology, applied in building components, building insulation materials, construction, etc., can solve the problems of insufficient viscosity of rubberized asphalt concrete, inability to use special pavements, application limitations, etc., achieve excellent high temperature toughness and low temperature flexibility, improve cohesion , the effect of high dynamic viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A rubberized asphalt concrete, which is prepared by mixing high-viscosity rubber asphalt and graded stones at high temperature, paving and rolling, to obtain asphalt concrete, and the mixing and stirring temperature is 170-185 DEG C; the high-viscosity rubber asphalt comprises 100 parts of asphalt, 5 parts of Parts of rubber powder, 3 parts of SBS, 1.5 parts of oxidized polyethylene wax, 0.1 part of first crosslinking aid, 3 parts of aromatic oil and 0.3 part of second crosslinking aid.

[0035] Among them, the asphalt is selected from petroleum asphalt, the rubber powder is selected from 40 to 120 mesh, and the first cross-linking assistant is DCP dicumyl peroxide, DTBP di-tert-butyl peroxide, 2,5-dimethyl-2,5-di- A kind of tert-butyl peroxide hexane (double 25); a kind of second cross-linking assistant sulfur, TMTD, DCP, M-promoting or D-promoting.

[0036] The preparation method of above-mentioned high-viscosity rubber asphalt, comprises the following steps:

[0037...

Embodiment 2~13 and comparative example 1~3

[0044] The only difference from Example 1 is that the distribution ratio of each component of the high-viscosity asphalt is different, and the specific component distribution ratio is shown in Table 1 below.

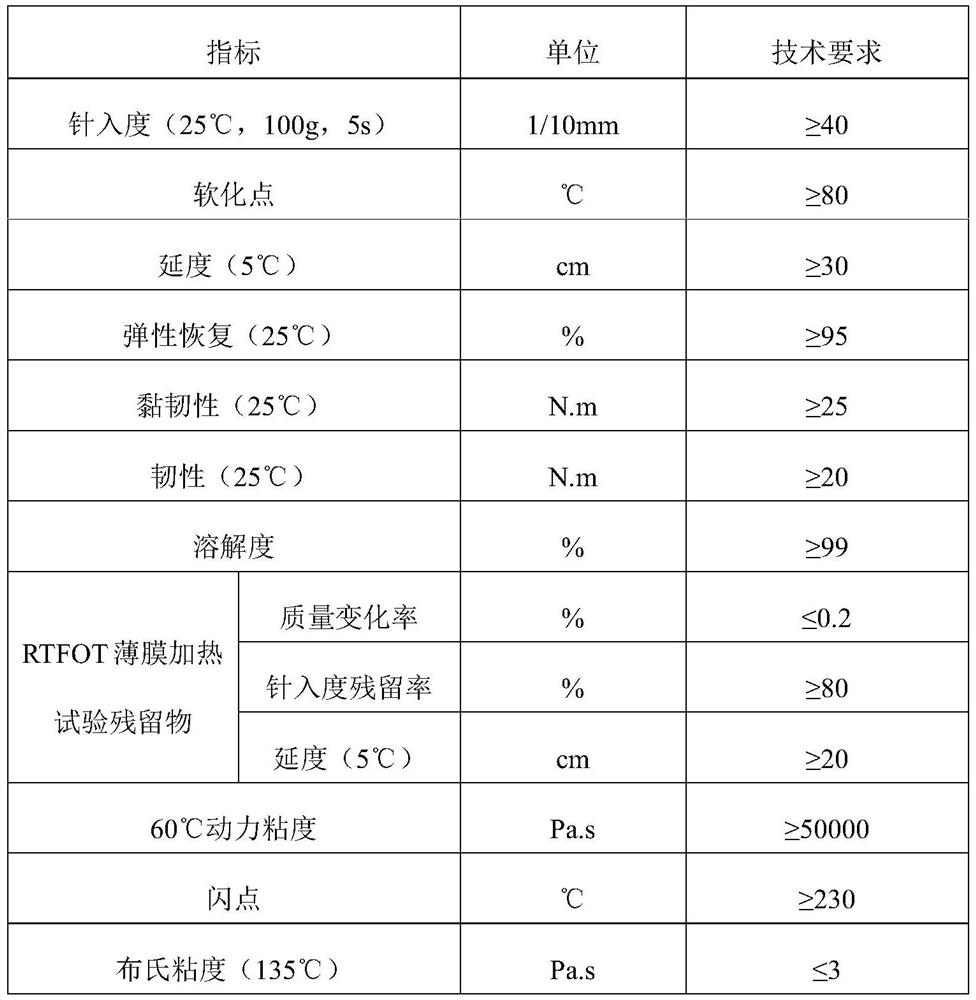

[0045] Table 1 shows the composition ratios of Examples 1 to 13 and Comparative Examples 1 to 3

[0046] asphalt rubber powder SBS Oxidized polyethylene wax Aromatic oil first cross-linking aid Second Crosslinking Auxiliary Example 1 100 5 3 1.5 3 0.1 0.3 Example 2 100 10 3 1.5 3 0.1 0.3 Example 3 100 15 3 1.5 3 0.1 0.3 Example 4 100 10 2 1.5 3 0.1 0.3 Example 5 100 10 7 1.5 3 0.1 0.3 Example 6 100 10 3 0.5 3 0.1 0.3 Example 7 100 10 3 3 3 0.1 0.3 Example 8 100 10 3 1.5 1 0.1 0.3 Example 9 100 10 3 1.5 4 0.1 0.3 Example 10 100 10 3 1.5 3 0.04 0.3 Example 11 100 10 3 1.5 3 0.4 0.3 Example 12 100 10 3 1.5 3 0.4...

Embodiment 14

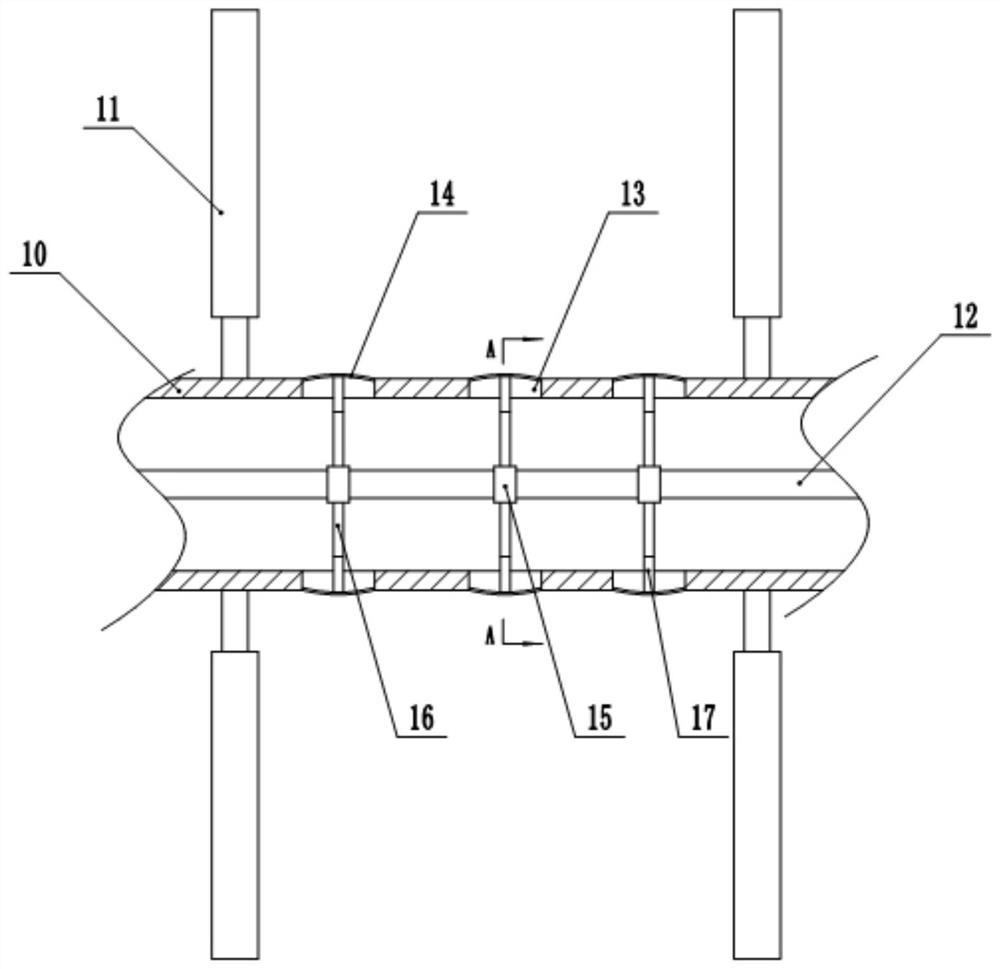

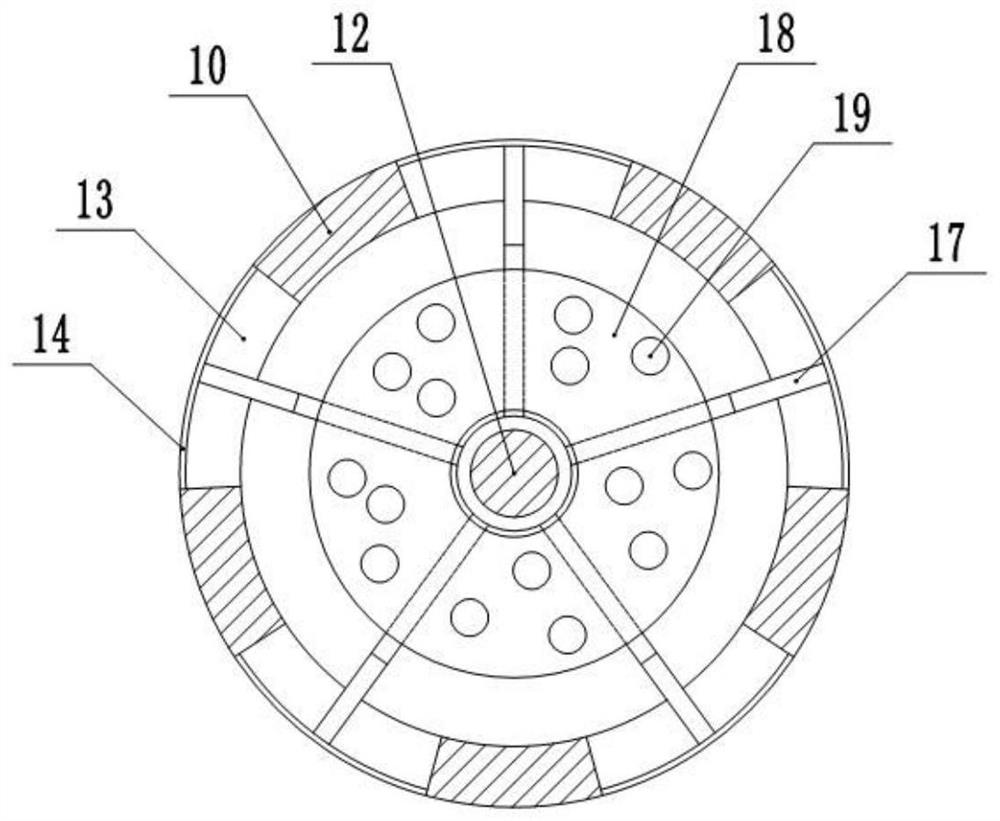

[0048] The difference from Example 2 is that in step S3 of the high-viscosity rubber asphalt preparation method, a specially-made stirring device is used, combined with figure 1 and figure 2 As shown, the special stirring equipment includes a horizontally fixed stirring drum, an inlet is provided at the left end of the stirring drum, an outlet is provided at the right end, and a stirring shaft 10 is rotatably connected in the stirring drum, wherein the stirring shaft 10 is hollow and arranged on two sides of the stirring shaft 10. Both ends are connected with pipes through rotary joints, and several stirring blades 11 are fixed on the stirring shaft 10, and the heating medium (gas, water, liquid metal, etc.) flows through the stirring shaft 10 through the pipes, thereby heating the stirring shaft 10 and stirring blades 11, A driving mechanism for driving the stirring shaft 10 to rotate is also provided.

[0049] A connecting rod 12 is slidably connected in the stirring shaft 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com