A kind of asphalt mixture adopting direct-throwing high-adhesion modifier and its preparation method

A kind of asphalt mixture, high adhesion technology, applied in the direction of building insulation materials, building components, buildings, etc., can solve the problem of affecting the water damage resistance of asphalt mixture, weak bonding force of rubber powder asphalt interface, limited activation of rubber powder, etc. problems, to save economic costs, reduce the amount of asphalt, high adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

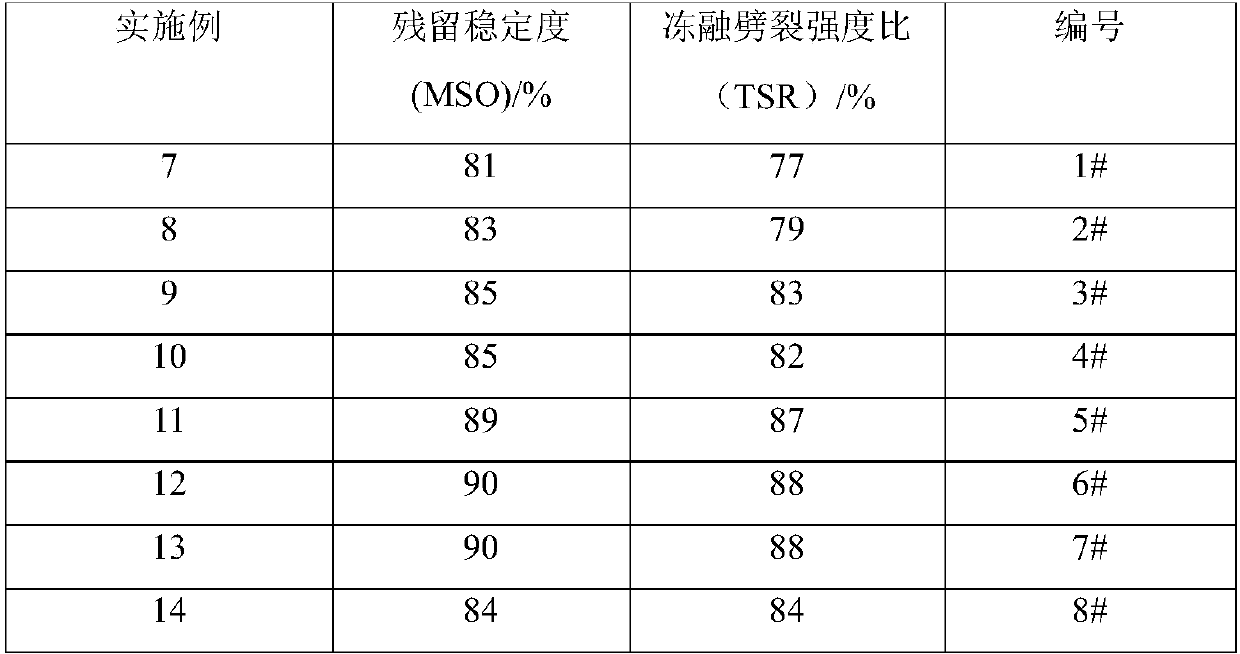

Examples

Embodiment 1

[0049] Pretreat rubber powder, softening oil, and activator in a high-speed mixer at 70°C for 15 minutes according to the weight ratio: 100:3:0.5, and add them to the first twin-screw extruder. Extrusion of high devulcanization regenerated rubber. Subsequently, the regenerated rubber with high desulfurization degree is metered into the second screw extruder through the connector, and the feeding speed of the hopper is adjusted according to the mass ratio of regenerated rubber with high desulfurization degree, modified high-temperature coal tar pitch, and skeleton proppant: 50:40 : 10 was added and uniformly mixed, extruded, and prepared through water-cooled granulation to prepare a direct-throwing high-adhesive asphalt mixture modifier.

Embodiment 2

[0051] Pretreat rubber powder, softening oil, and activator in a high-speed mixer at 70°C for 15 minutes according to the weight ratio: 100:5:0.3, and add them to the first twin-screw extruder. Extrusion of high devulcanization regenerated rubber. Subsequently, the high desulfurization regenerated rubber is metered into the second screw extruder through the connector, and the feeding speed of the hopper is adjusted according to the mass ratio of high desulfurization regenerated rubber, modified high-temperature coal tar pitch, and skeleton proppant: 50:45 : 5 was added and evenly mixed, extruded, and prepared through water-cooled granulation to prepare a direct-throwing high-adhesive asphalt mixture modifier.

Embodiment 3

[0053] Pretreat rubber powder, softening oil, and activator in a high-speed mixer at 70°C for 15 minutes according to the weight ratio: 100:8:2, and meter them into the first twin-screw extruder. Extrusion of high devulcanization regenerated rubber. Subsequently, the regenerated rubber with high desulfurization degree is metered into the second screw extruder through the connector, and the feeding speed of the hopper is adjusted according to the mass ratio of regenerated rubber with high desulfurization degree, modified high-temperature coal tar pitch, and skeleton proppant: 50:35 : 15 was added and uniformly mixed, extruded, and prepared through water-cooled granulation to prepare a direct-throwing high-adhesive asphalt mixture modifier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com