Hydraulic compound valve based on sequential pressure reduction overflow function

A compound valve and function technology, applied in the direction of fluid pressure actuating devices, servo motor components, mechanical equipment, etc., can solve the problems of use, installation and maintenance, etc., achieve a small number of parts, and realize the function and structure of sequential decompression and overflow. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

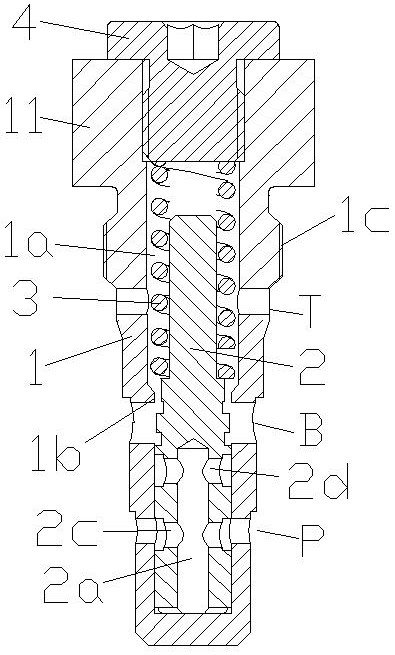

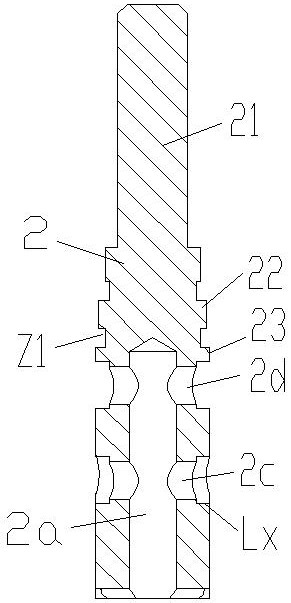

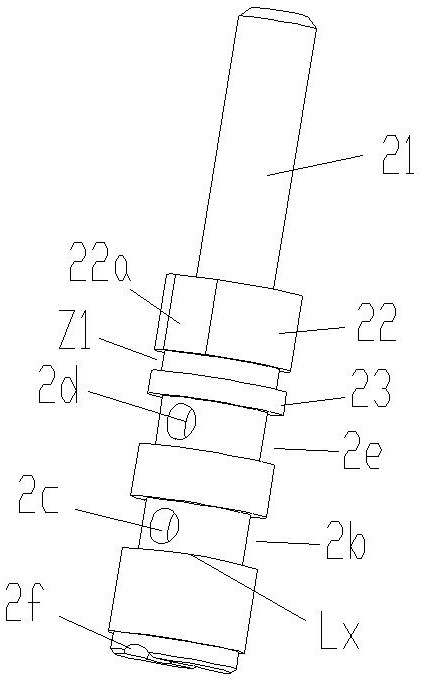

[0024] Figures 1 to 7 It is a schematic diagram of the structure and principle of the present invention.

[0025] The reference signs are: action surface S, sealing ring M, damping channel Z, annular damping groove Z1, throttling area Ax, control edge Lx, mouth edge Lt, valve sleeve 1, valve cavity 1a, inner shoulder 1b, External thread 1c, positioning boss 11, valve core 2, central oil passage 2a, annular control groove 2b, pressure oil port 2c, connecting oil hole 2d, annular connecting groove 2e, bottom groove 2f, spring guide rod section 21, upper stage Shoulder 22, longitudinal section 22a, lower shoulder 23, pressure spring 3, pressure regulating screw plug 4, mounting part 5.

[0026] As shown in the figure, the present invention discloses a hydraulic composite valve based on the function of sequential decompression and overflow. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com