Automatic grafting equipment for commercial plants

An automatic grafting and plant technology, applied in the direction of grafting, etc., can solve the problems of wood fixation and single function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

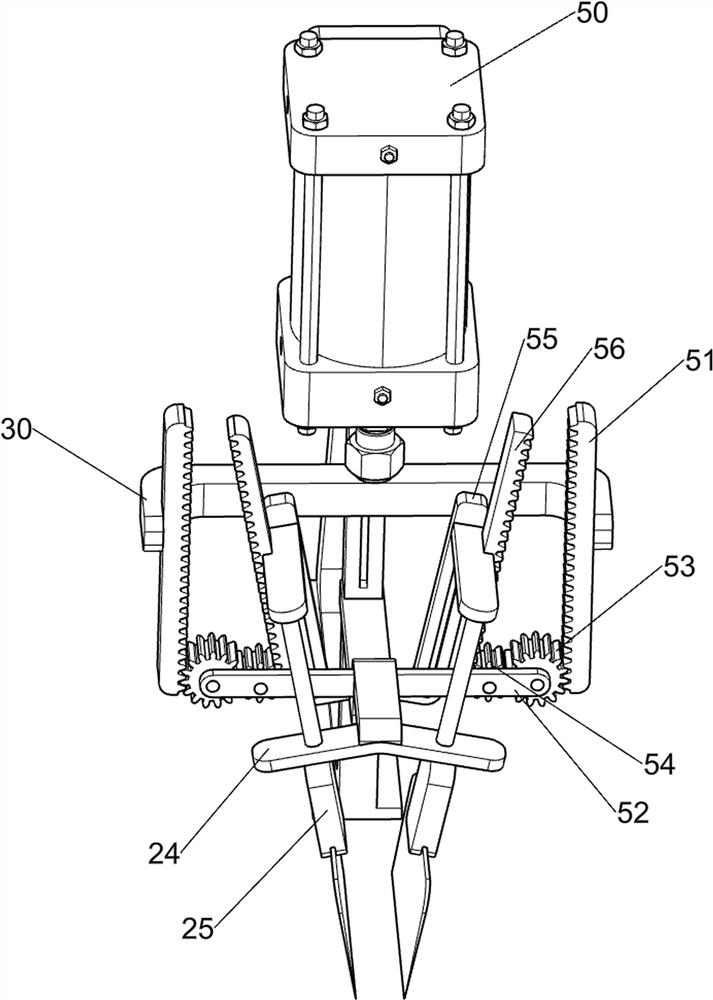

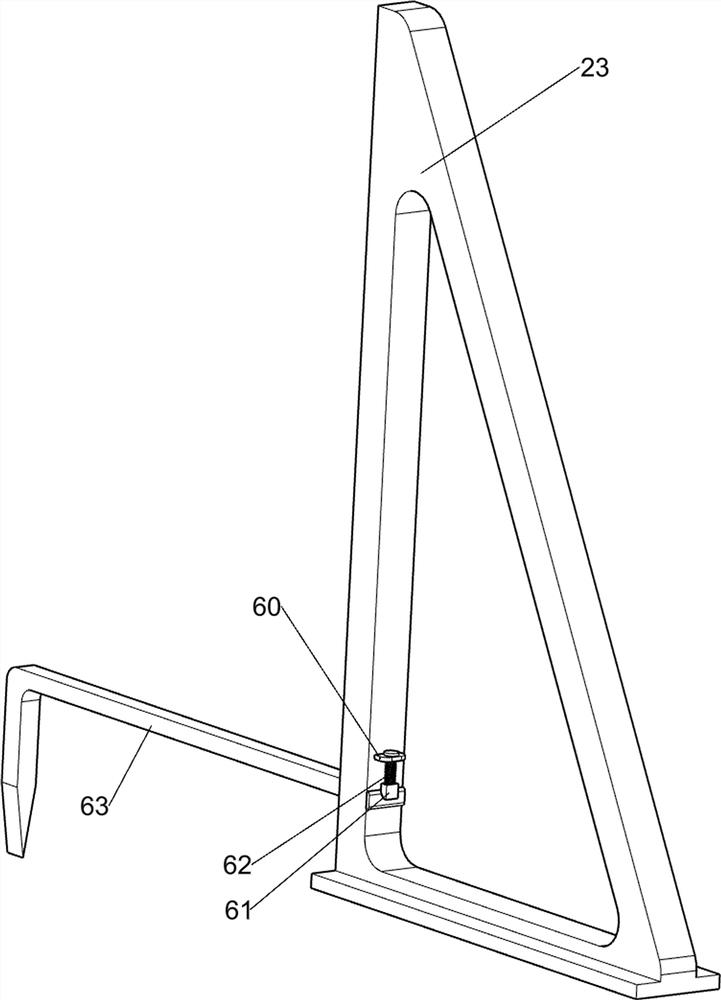

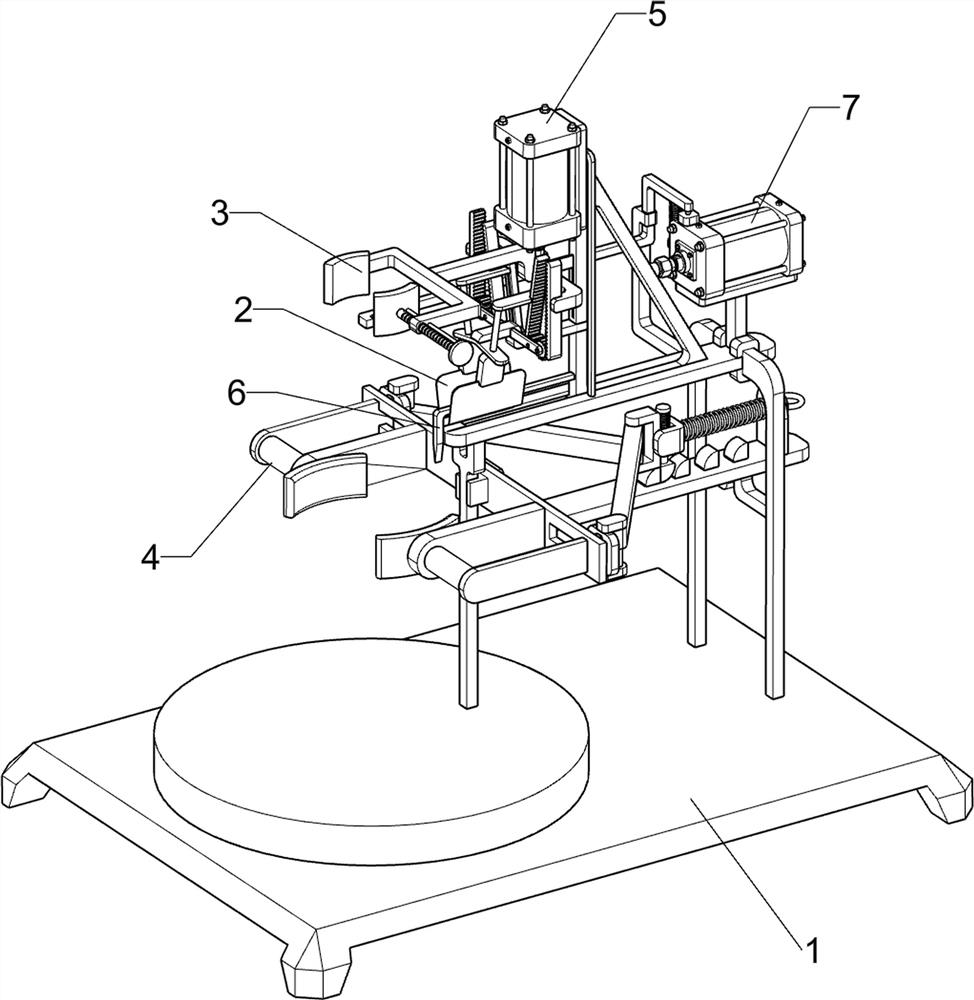

[0028] A commercial plant automatic grafting equipment, such as figure 1 , figure 2 , image 3 with Figure 5 As shown, it includes a base 1 , a cutting mechanism 2 and a grafting mechanism 3 , the base 1 is provided with a cutting mechanism 2 , and the cutting mechanism 2 is provided with a grafting mechanism 3 .

[0029] First people push the cutting mechanism 2 to the left, and the cutting mechanism 2 drives the grafting mechanism 3 to move to the left, then fix the branches to be grafted on the grafting mechanism 3, and then people can place the wood on the cutting mechanism 2, at this time The cutting part of the cutting mechanism 2 is located above the wood, and then people squeeze the cutting part of the cutting mechanism 2 downward, so that the cutting part of the cutting mechanism 2 can cut and slot the wood. After the slotting is completed, people can move the cutting part upwards and reset it , and push the cutting mechanism 2 to the right, the cutting mechanism...

Embodiment 2

[0034] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Image 6 with Figure 7 As shown, the clamping mechanism 4 is also included, and the clamping mechanism 4 includes a fourth connecting block 40, a guide plate 41, a second sliding block 42, a fifth connecting block 43, a sixth connecting block 44, a limit block 45, a Three slide blocks 46, the first spring 47, the fixed plate 48 and the second spring 49; The symmetrical sliding type is provided with a second slider 42, the second slider 42 slides on the guide plate 41, the mounting table 22 is provided with a fixed plate 48, the fixed plate 48 is connected with the fourth connecting block 40, and the sliding type on the fixed plate 48 Be provided with the 5th connecting block 43, the 5th connecting block 43 left side rotation type is provided with two the 6th connecting block 44, the 6th connecting block 44 is connected with the second sliding block 42 rotating type, fixed plate 48 right sides are e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com