A formwork trolley release agent brushing device and working method

A formwork trolley and release agent technology, which is applied to the device, coating, pretreatment surface, etc. for applying liquid to the surface, which can solve the problem of uneven application of release agent, high construction risk factor, and contaminated steel bars problem, to achieve the effect that is conducive to the overall stress, mature technology, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

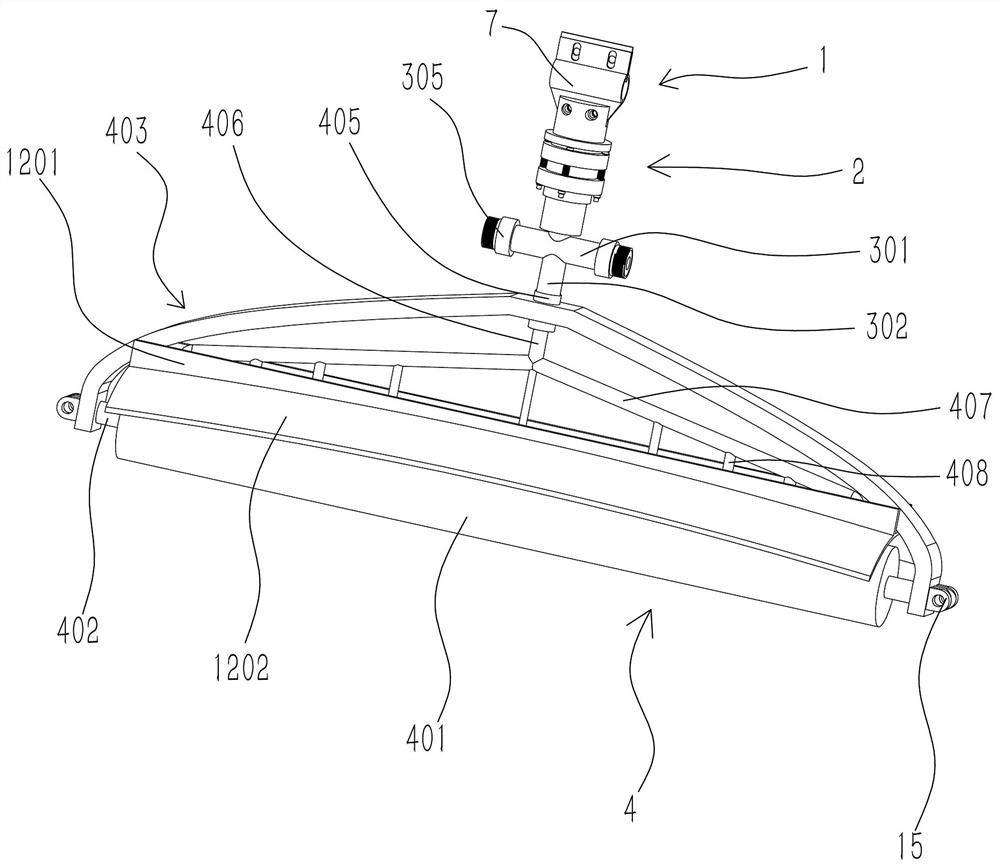

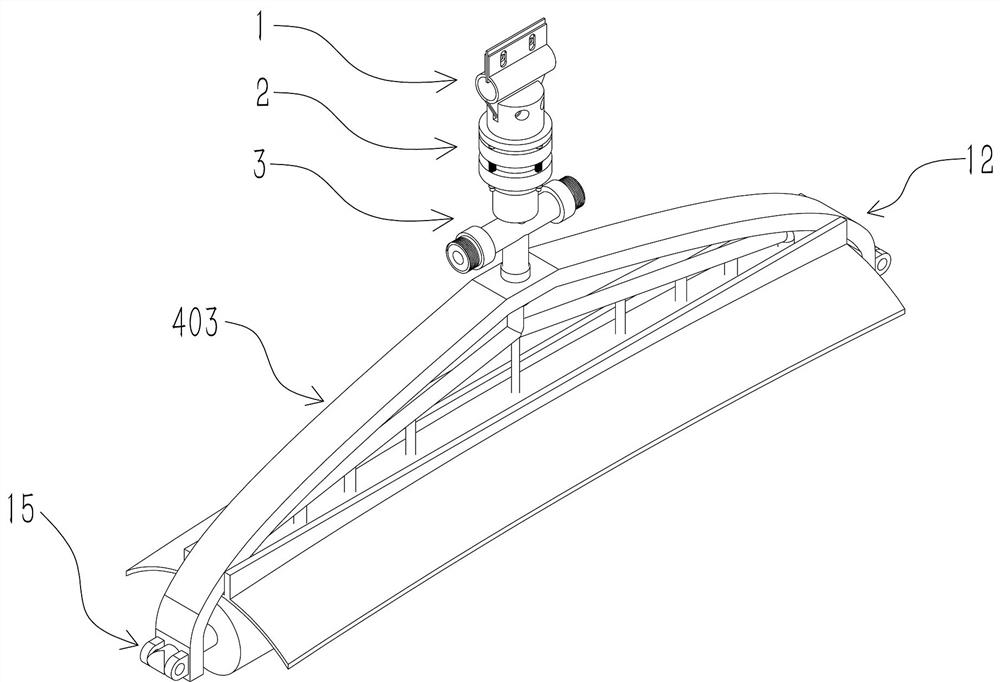

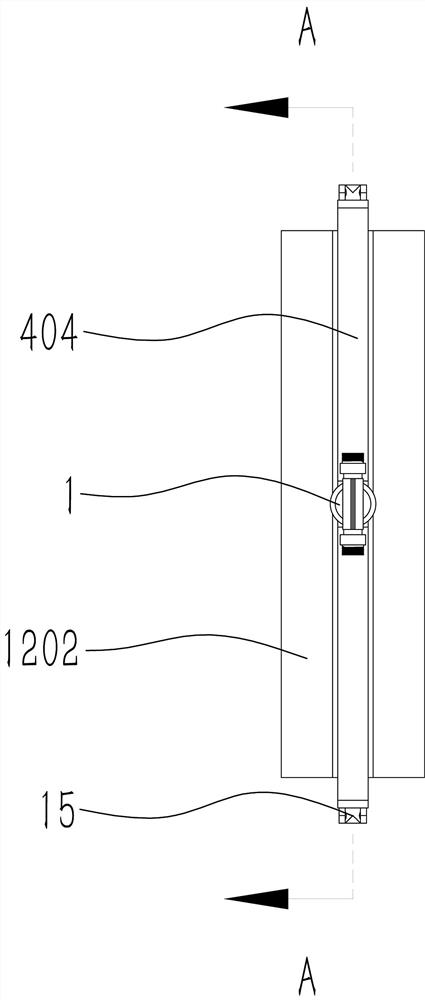

[0049] Such as Figure 1~16 As shown, a formwork trolley release agent brushing device includes a fixing device 1 and a release agent brushing system 4, the fixing device 1 is detachably installed on the tunnel lining steel bar 5, and the release agent brushing system 4 is located at On one side of the fixing device 1, the release agent brushing system 4 includes a support frame 403, one side of the support frame 403 is connected to the fixing device 1, and the other side of the support frame 403 is provided with a roller 402, and the roller 402 is covered with a brush Roller 401 , the brushing roller 401 is used to brush against the outer surface of the steel template 6 . With this structure, the fixing device 1 is installed on the steel bar 5 , and the position of the support frame 403 relative to the steel template 6 is controlled by adjusting the state of the fixing device 1 , thereby ensuring the painting effect of the painting roller 401 .

[0050] In a preferred soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com