Thread clamping fixture and secondary clamping machining method for high-precision bolt

A thread and clamping technology, which is applied in the field of thread clamping fixtures and secondary clamping processing of high-precision bolts, can solve the problems of low pass rate and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

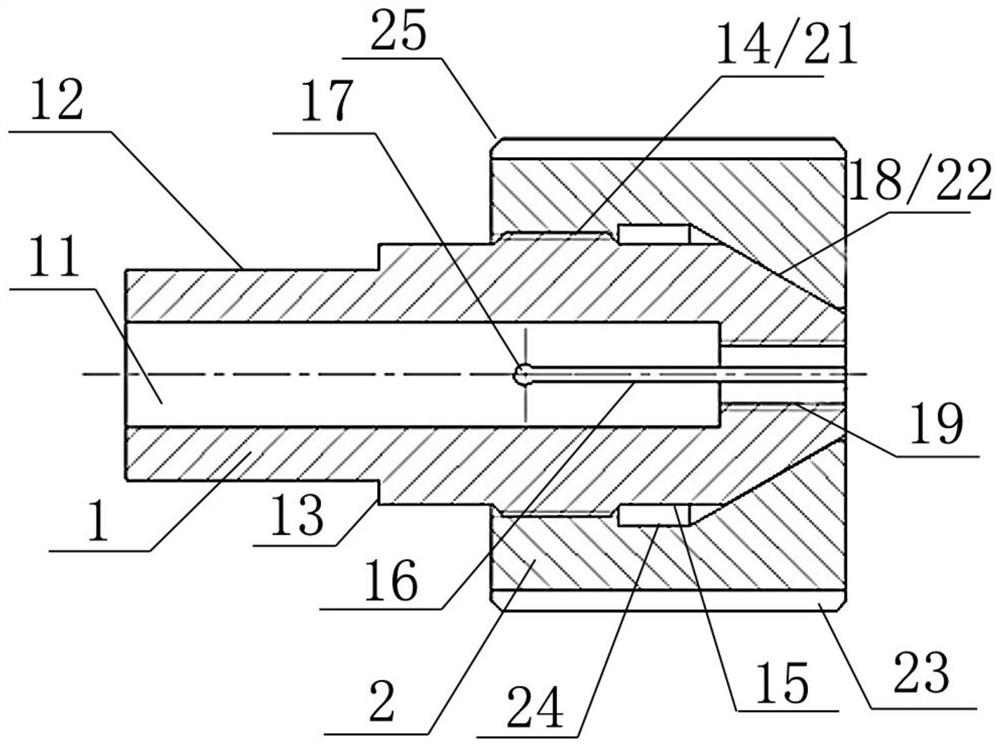

[0039] The invention provides a threaded clamping fixture, such as figure 1 As shown, it includes a clip body 1 and a lock nut 2 .

[0040] The clamp body 1 has an internal through hole 11. One end of the clamp body 1 has a clamping handle 12 for clamping the machine tool, and the other end has a clamp threaded hole 19 for clamping the bolt workpiece inside. The clamp threaded hole 19 A plurality of axial opening grooves 16 are opened around so that this section can be contracted and deformed. The length of the opening grooves 16 is greater than the length of the threaded hole 19 of the clamp and is not greater than the axial length of the lock nut 2. The outside of the front end of the clamp body 1 has a The external thread 14 that the clamp nut 2 cooperates has a clamp body transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com