Three-section V-shaped series-parallel combined magnetic pole adjustable flux motor

A technology of combined magnetic poles and flux motors, which is applied in the direction of magnetic circuits, synchronous machines, electric components, etc., can solve the problems that the advantages of series-parallel adjustable flux motors cannot be taken into account, so as to achieve the effect of magnetic adjustment, improve stability, Reduced effect of magnetizing current pulses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

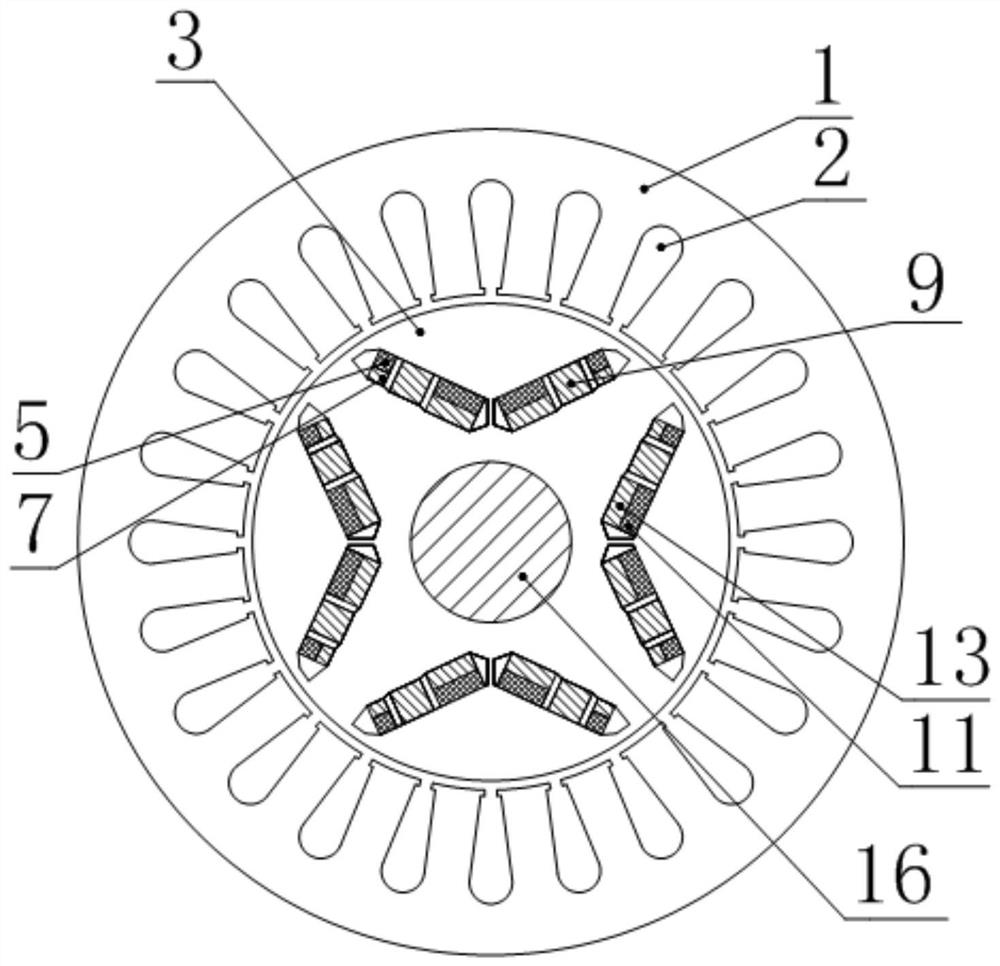

[0033] Specific implementation mode one: the following combination Figure 1 to Figure 7 To illustrate this embodiment, the three-stage V-type series-parallel combination magnetic pole adjustable flux motor described in this embodiment includes a stator core 1, a stator winding 2, a rotor core 3 and a rotating shaft 16; the rotor core 3 is fixed on the rotating shaft 16, And located inside the stator core 1, the armature winding 2 is arranged on the stator core 1;

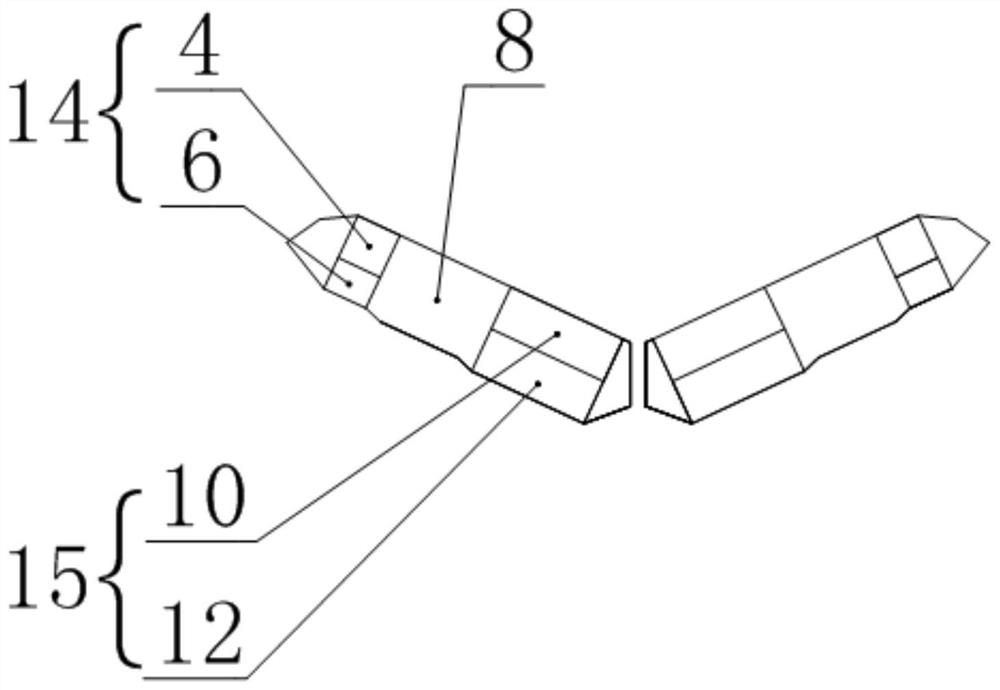

[0034] A V-shaped permanent magnet slot is arranged under each magnetic pole of the rotor core 3. The V-shaped permanent magnet slot is composed of two in-line slots arranged symmetrically. The in-line slot is a three-stage structure, and along the length direction From the outside to the inside, the outer tank body 14, the middle tank body 8 and the inner tank body 15 are sequentially connected to form, and the outer tank body 14 is composed of a No. 1 high-coercivity permanent magnet slot 4 and a No. 1 low-coerci...

specific Embodiment approach 2

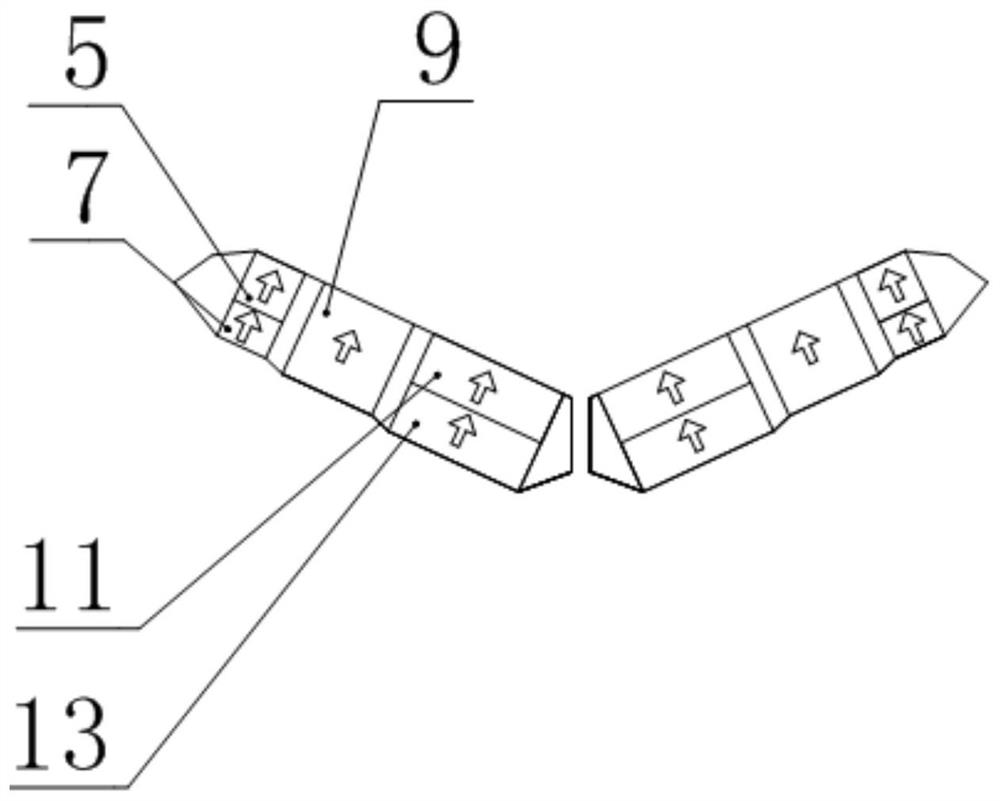

[0055] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the layout of two pairs of permanent magnets connected in series with the magnetic circuit is divided into the following two types:

[0056] The first layout method: No. 1 high-coercivity permanent magnet slot 4 and No. 2 high-coercivity permanent magnet slot 10 are close to the inside of the V-shaped permanent magnet slot at the same time, No. 1 low-coercivity permanent magnet slot 6 and No. 2 low-coercivity permanent magnet slot The coercivity permanent magnet groove 12 is close to the outside of the V-shaped permanent magnet groove at the same time;

[0057] The second layout mode: No. 1 high-coercivity permanent magnet slot 4 and No. 2 high-coercivity permanent magnet slot 10 are close to the outside of the V-shaped permanent magnet slot at the same time, No. 1 low-coercivity permanent magnet slot 6 and No. 2 low-coercivity permanent magnet slot The coercivity permanent magnet groove 12 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coercivity | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com