GAS flow METER

A technology of gas flowmeter and flowmeter, which is applied in the direction of volume measurement, liquid/fluid solid measurement, flow/mass flow measurement, etc. It can solve filter mesh clogging, filter mesh clogging, filter pressure loss increase, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

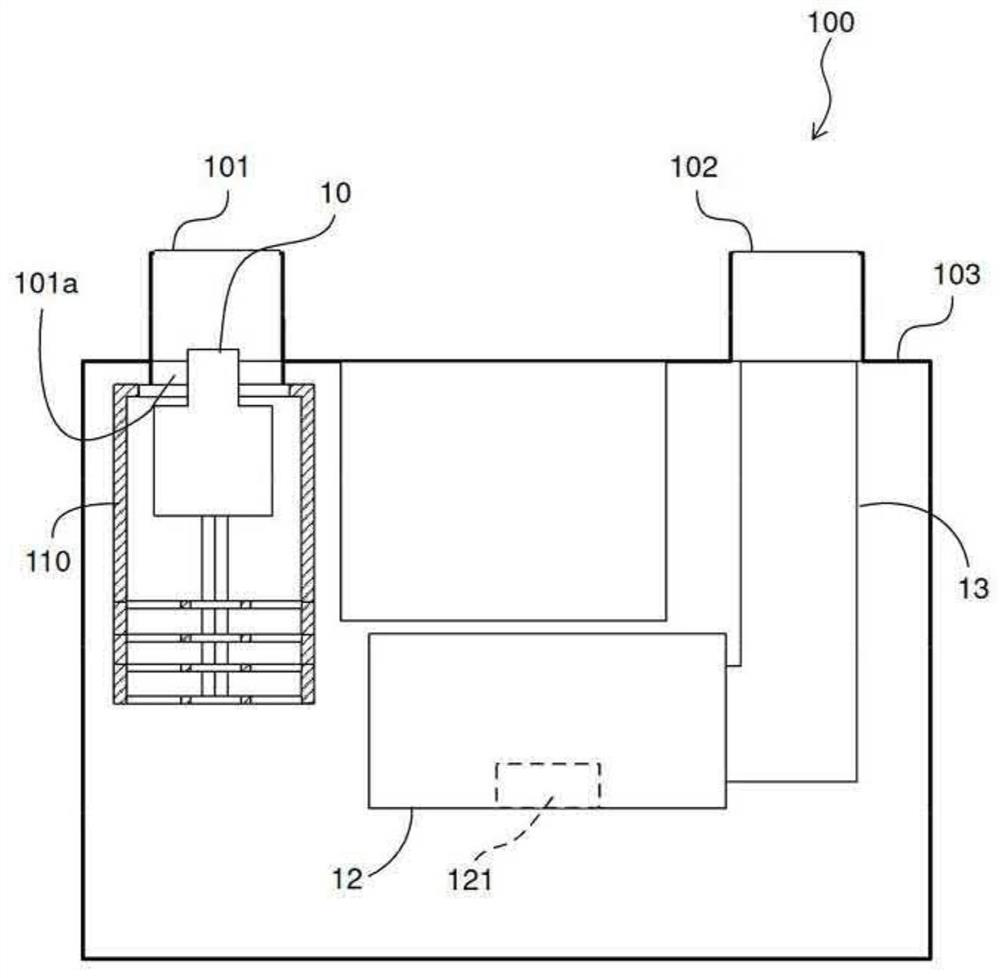

[0034] Such as figure 1 As shown, the gas flow meter 100 of the embodiment has a shut-off valve 10 and a filter device 11 (in figure 1 Only the support portion 110 is shown in . The stop valve 10 opens and closes the inflow opening 101 a communicating with the flowmeter inlet 101 of the gas flowmeter 100 and facing the inner opening of the gas flowmeter body 103 . The filter device 11 covers the opening 101 a and removes dust from the gas flowing in from the flowmeter inlet 101 . Since dust is removed by the filter device 11, high-precision flow measurement can be performed in the flow measurement unit 12 provided on the downstream side.

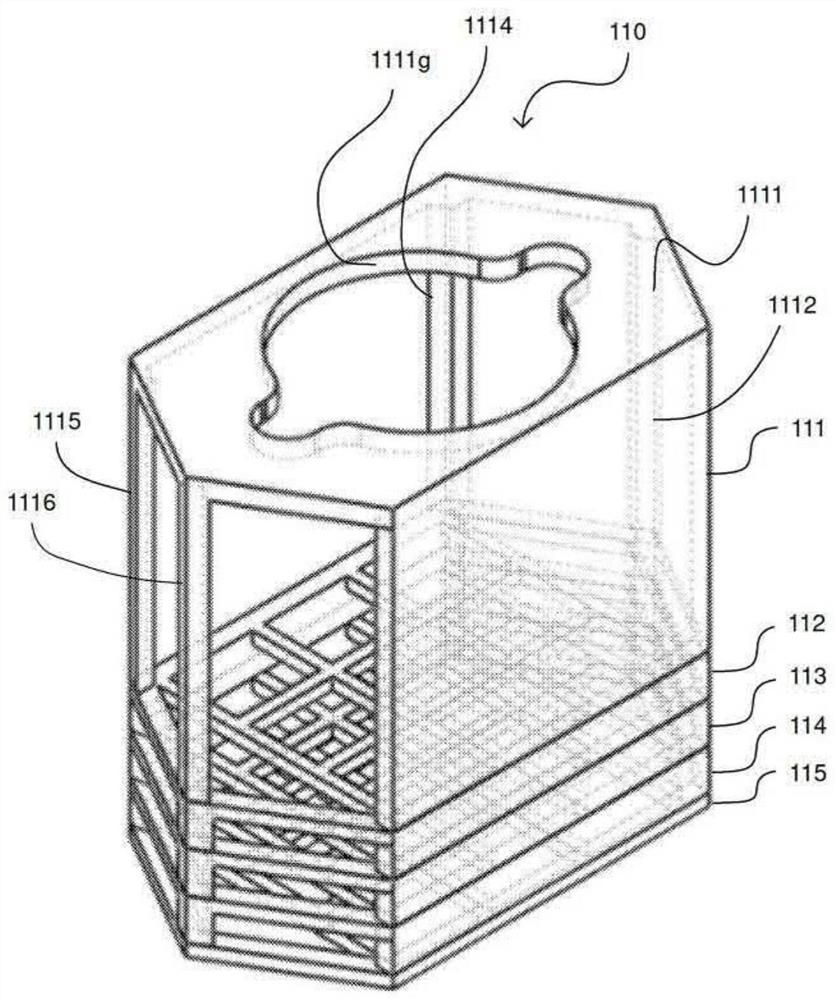

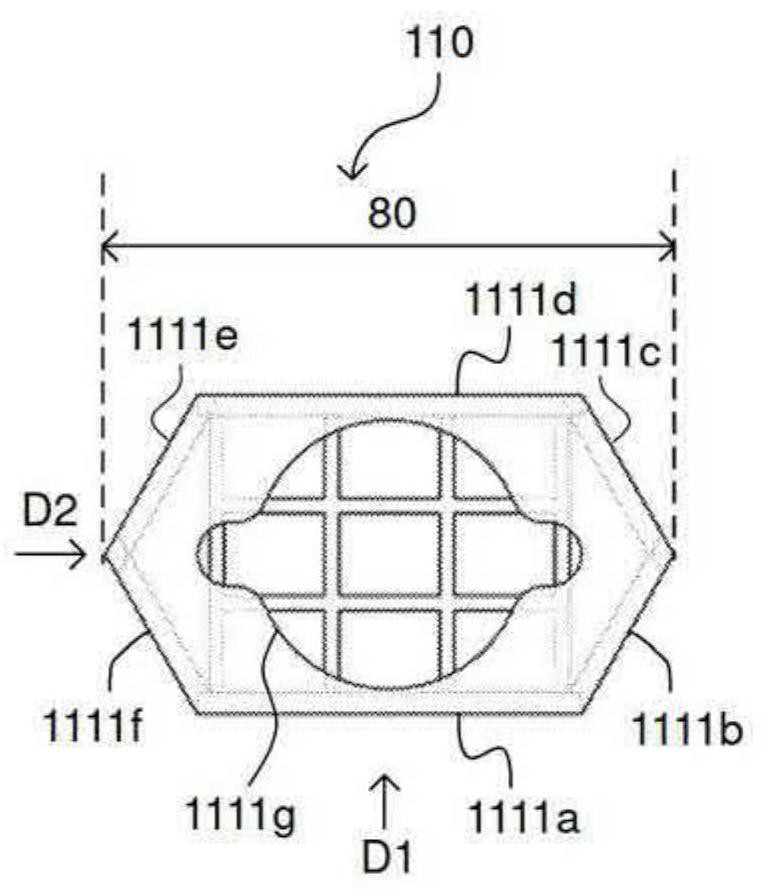

[0035] The filter device 11 has a support portion 110 and a filter 116 supported on the support portion 110 (refer to Figure 5 ). The support portion 110 has a plurality of stepped portions 112 to 115 stacked thereunder. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com