Edge covering device

An edge wrapping device and edge wrapping technology can be applied to buildings, building structures and other directions, which can solve problems such as low work efficiency, and achieve the effect of improving work efficiency, high precision and good wrapping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

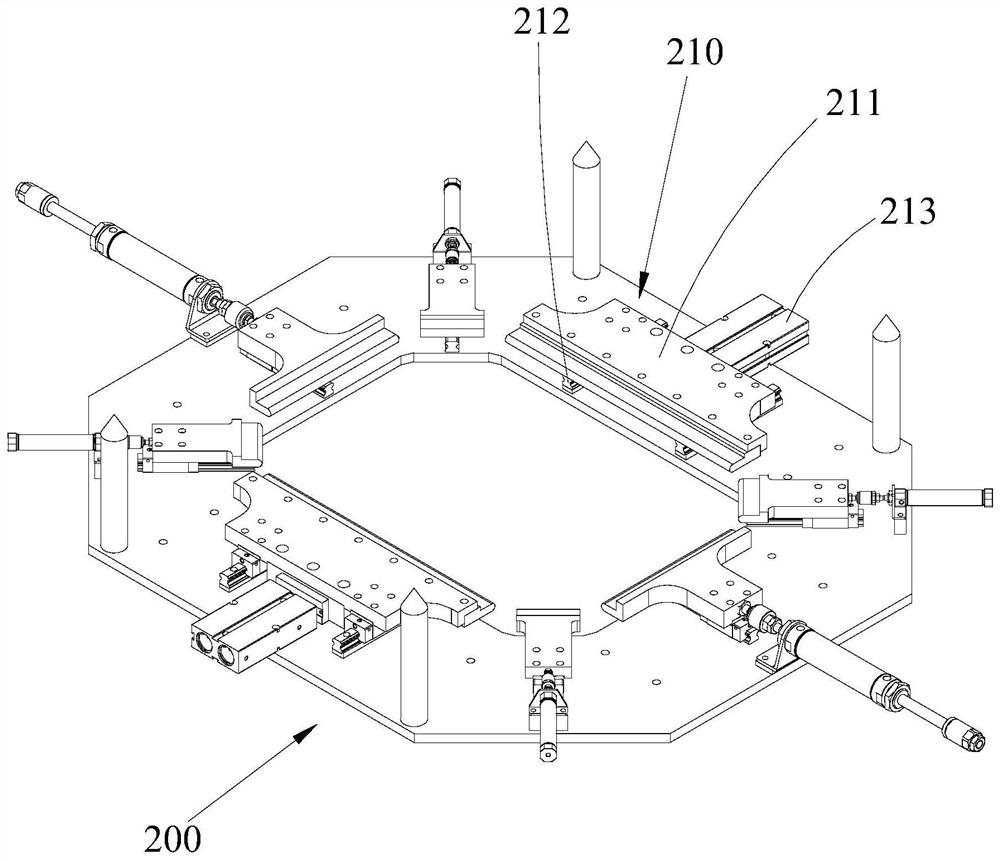

[0045] see image 3 As a specific embodiment of the hemming device provided by the present invention, the hemming assembly 200 includes a plurality of circumferentially distributed push-and-wipe mechanisms 210, and the push-and-wipe mechanism 210 includes a wiper head 211, a sliding joint 212, and a power piece 213, The wipe head 211 is slidably connected to the sliding joint 212 , and the power member 213 is used to drive the wipe head 211 to slide along the extending direction of the sliding joint 212 , so that the wipe head 211 pushes and wipes the protruding portion 22 to continue to fold the second bending angle. The specific working principle is: the power part 213 pushes out to drive the wiping head 211 to slide along the extension direction of the sliding joint 212, so that the wiping head 211 stamps the side of the corresponding protrusion 22 until the protrusion 22 is stamped Then the power part 213 retracts to drive the wiping head 211 to reset, and completes the se...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap