Four-degree-of-freedom parallel mechanism with large-angle-torsion movable platform and composite branched chains

A rotating platform and large-angle technology, which is applied in the direction of manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as the limitation of the range of rotational freedom, and achieve the effects of reducing manufacturing and processing difficulty, simple structure, and reducing mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

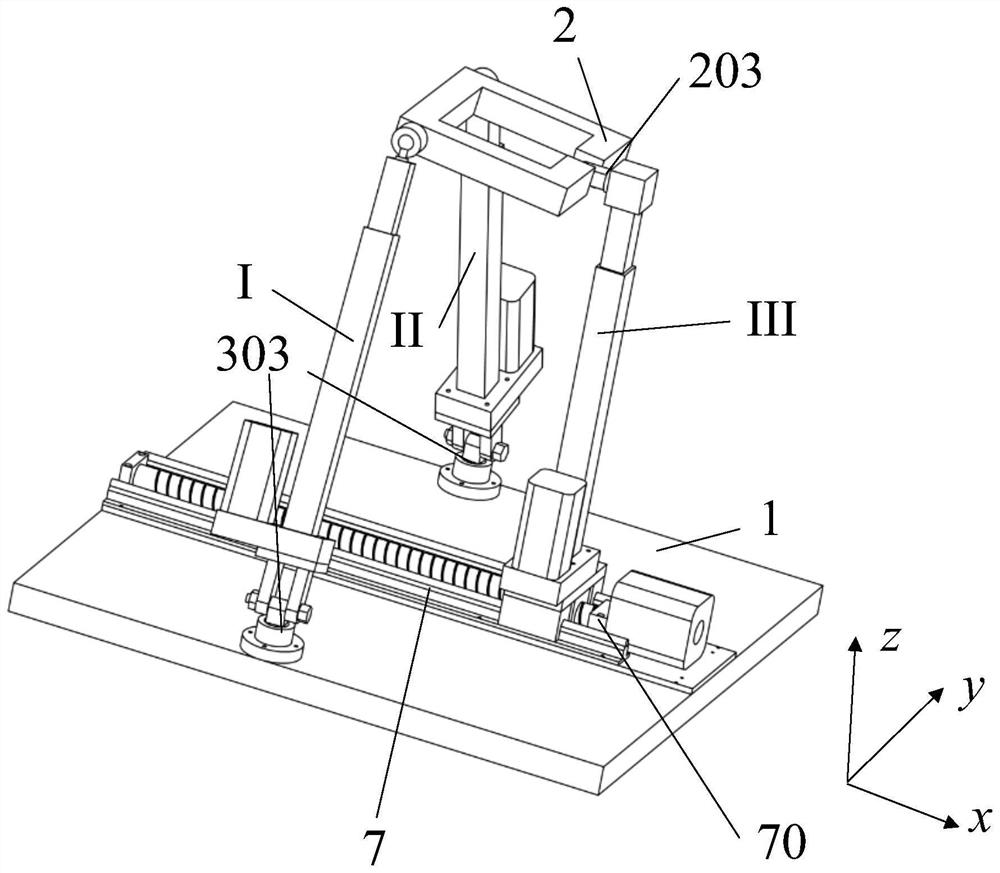

[0023] The four-degree-of-freedom parallel mechanism provided by the present invention with a large-angle twistable platform and a composite branch chain will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] Such as figure 1 — Image 6 As shown, the four-degree-of-freedom parallel mechanism provided by the present invention has a large-angle twistable rotating platform and a composite branch chain, including a fixed platform 1, a moving platform 2, the first branch chain I, the second branch chain II and the third branch chain III ;

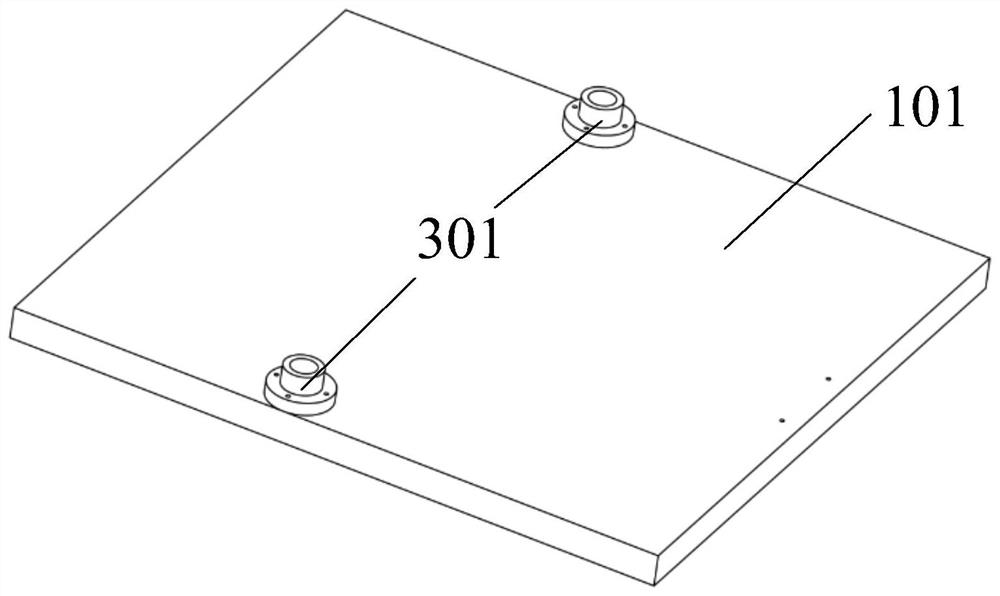

[0025] Wherein, the fixed platform 1 includes a base plate 101 and two second rotating supports 301; the two second rotating supports 301 are respectively fixed in the middle of both sides of the upper surface of the fixed platform 1, and the central axis is perpendicular to the upper surface of the base plate 101 ;

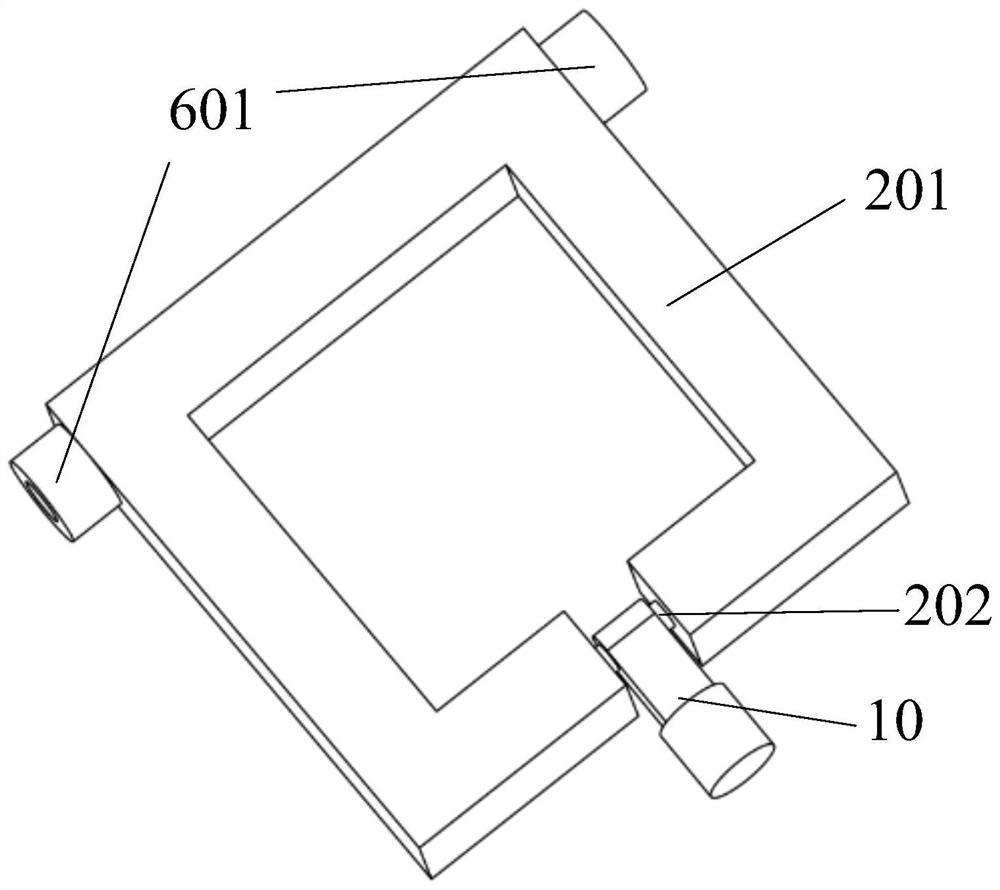

[0026] The moving platform 2 includes a platen 201, two spherical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com