Mold assembly

A component and mold technology, applied in the field of mold components, can solve problems such as insufficient spring compression space, and achieve the effect of solving poor product appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

[0024] The big mouth end in this article refers to the end of the longer base of the trapezoid, and does not have other special meanings.

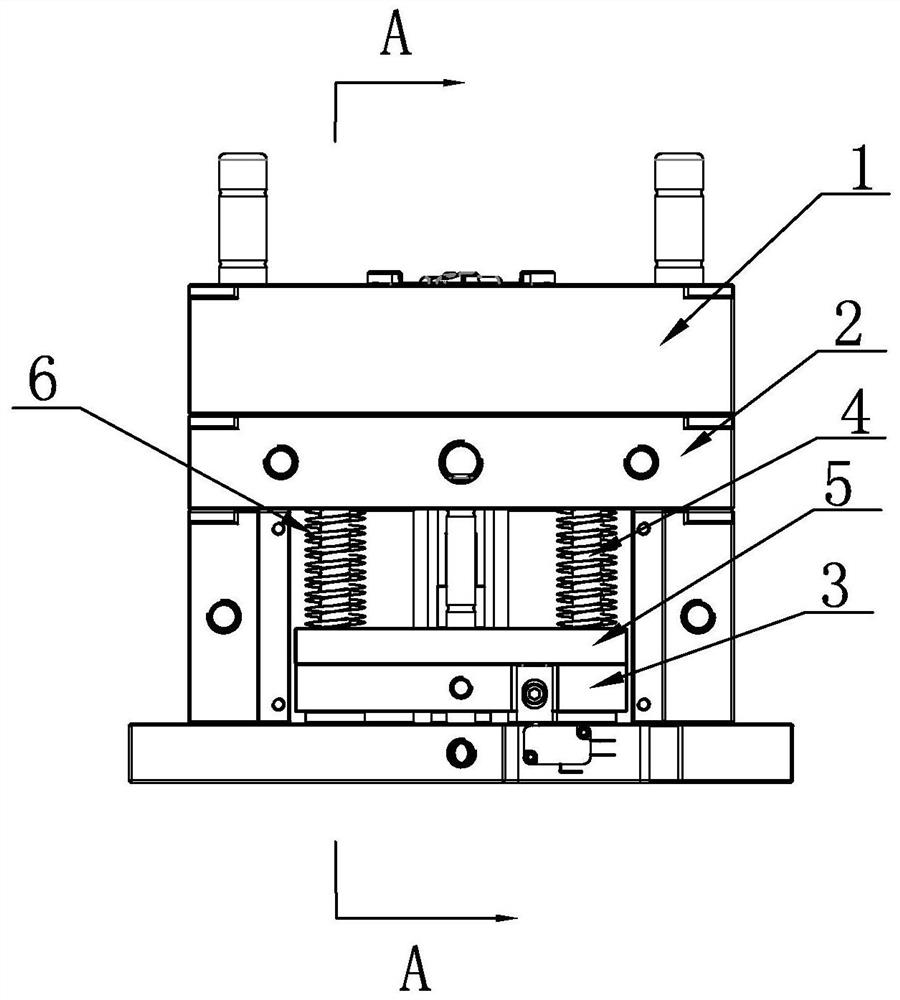

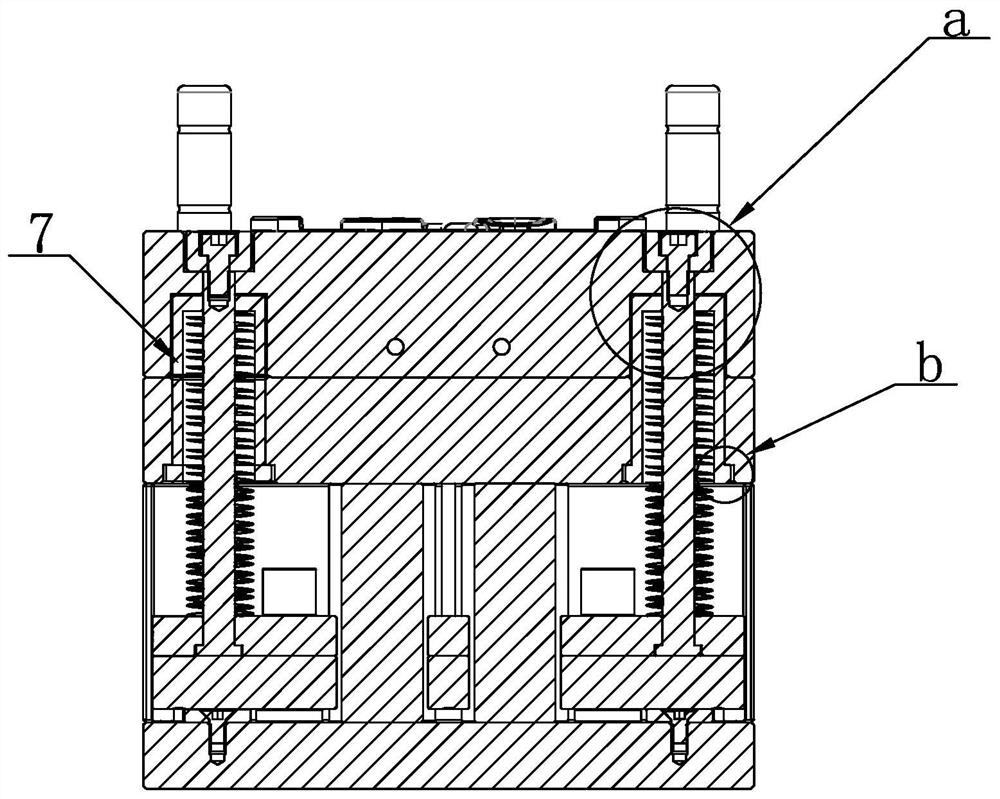

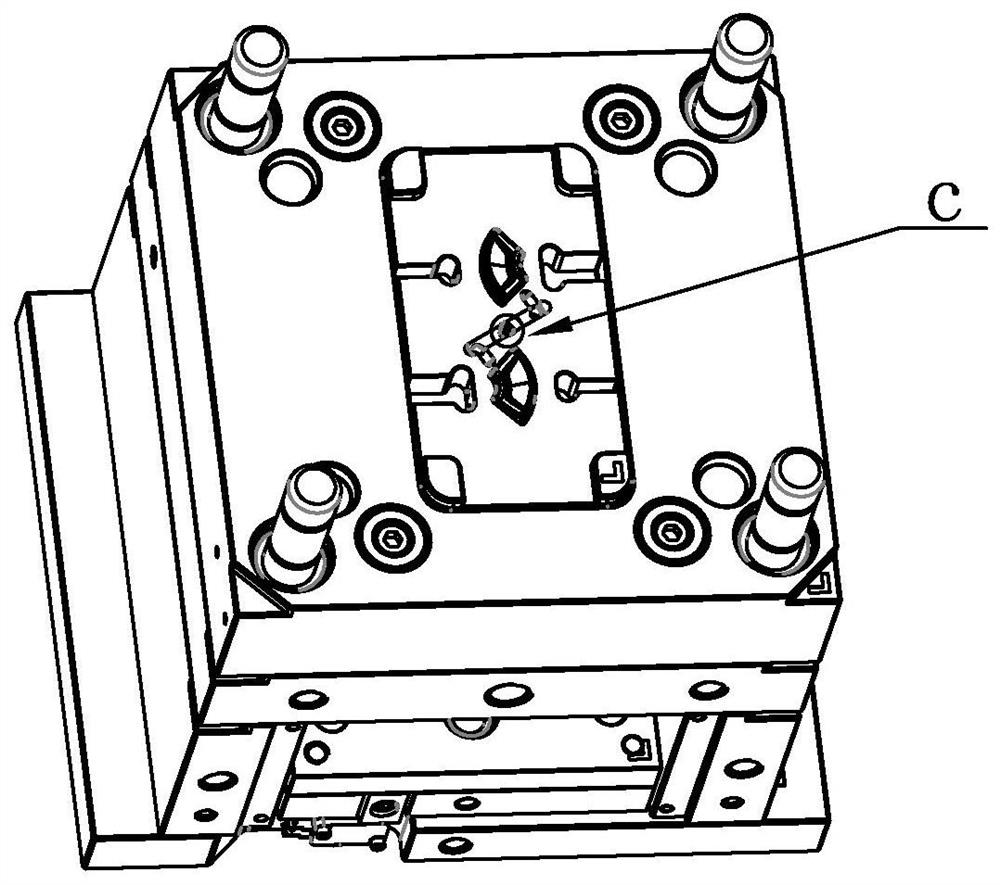

[0025] The disclosure of the present invention relates to a mold assembly, comprising a push plate 1, a template 2, a thimble base plate 3 and a thimble panel 5 equipped with a thimble 4 arranged in sequence, and the thimble base plate 3 can drive the thimble panel 5 and the thimble 4 to move in the direction of the push plate 1 , the thimble 4 is linked with the push plate 1, and the thimble 4 is also covered with a spring 6. In the embodiment of the present invention, a spring sleeve 7 is also included, and the side of the push plate 1 facing the template 2 is provided with a cavity 111 , the spring sleeve 7 extends through the template 2 into the cavity 111, the top of the spring sleeve 7 is provided with a su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com