Never-loosening fastener

A technology for fasteners and mechanical parts, which is applied in the direction of threaded fasteners, locking fasteners, connecting components, etc. It can solve the problems of loosening and falling off, self-locking is not firm, etc., and achieves small friction, not easy to wear, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

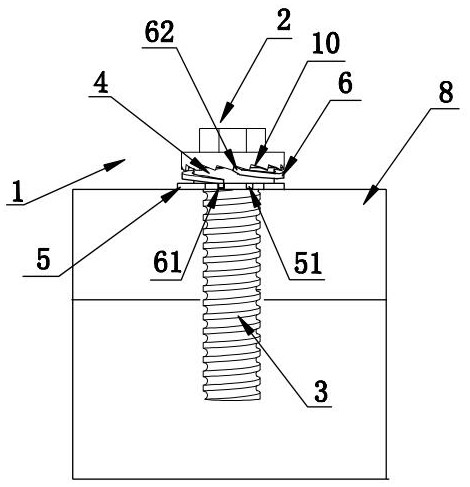

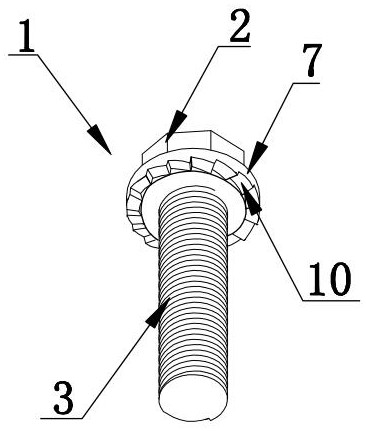

[0033] A fastener that never loosens, suitable for parts with thick fastening parts 8, such as Figure 1 to Figure 6As shown, its structure includes a screw body 1, a backing ring 4, a spacer 5 and an elastic clip 6. The screw 1 includes a screw rod 3 and a screw head 2 with a brim 7. The elastic clip 6 is a helical, horizontal The cross-section is a rectangular strip-shaped spiral structure, and the width of the elastic card 6 is more than twice the thickness. Since the elastic card 6 is spiral, both ends have a certain inclination angle to the direction of the two ends, and the elastic card 6 One end is bent downwards and forms a right angle as the starting end 61 , and the other end is slightly tilted up on the basis of a certain inclination angle to form an end 62 . The height of the elastic clip 6 in a relaxed state is greater than the height of the backing ring 4, and the inner diameter of the elastic clip 6 is slightly larger than the outer diameter of the backing ring ...

Embodiment 2

[0038] This preferred embodiment provides a fastener that never loosens, such as Figure 7 to Figure 8 As shown, the difference from embodiment 1 is that this embodiment 2 is suitable for parts with thin fastening parts that require nuts to cooperate. This embodiment includes screw body 1, washer 5, backing ring 4, elastic clip 6 and Nut 9, screw body 1 includes screw rod 3, wherein the structure of elastic clip 6, backing ring 4 and gasket 5 is the same as the structure of elastic clip 6, backing ring 4 and gasket 5 in embodiment 1, and nut 9 is also A brim 7 is provided, and the distance between the brim 7 of the nut 9 and the radius of the elastic card 6 is the same as that of the bottom surface of the brim 7 of the screw head 2 of the first embodiment. Groove 10, and the triangular groove 10 is not provided under the brim 7 of the screw head 2 in the second embodiment. The implementation process is similar to that of Example 1. During implementation, the gasket 5, backing...

Embodiment 3

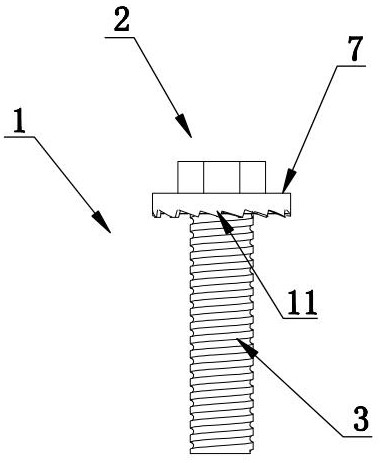

[0040] This preferred embodiment provides a fastener that never loosens, such as Figure 9 As shown, it is suitable for the parts 8 whose fastening parts are thinner and require the cooperation of nuts. The difference from Embodiment 2 is that the screw head 2 of the screw body 1 is provided with the same triangular shape as the bottom surface of the nut 9 brim 7 under the brim 7. The groove 10, the screw rod 4 of the screw body 1 passes through the machine part 8, and the part of the screw rod 3 outer circumference on both sides of the machine part 8 is equipped with a gasket 5, a backing ring 4 and an elastic clip 6, wherein the elastic clip 6, The structures of the backing ring 4 and the washer 5 are the same as those of the elastic clamp 6 , the backing ring 4 and the washer 5 in the second embodiment. The implementation process is similar to that of Example 2. The specific implementation process is as follows: firstly bond the two gaskets 5 to both sides of the machine pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com