Low-wear rolling type discharging carrier roller device for copper bar hydraulic drawing machine

A drawing machine and rolling technology, which is applied in the field of rolling unloading roller device, can solve problems such as roller wear, achieve the effect of reducing impact force and ensuring drawing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

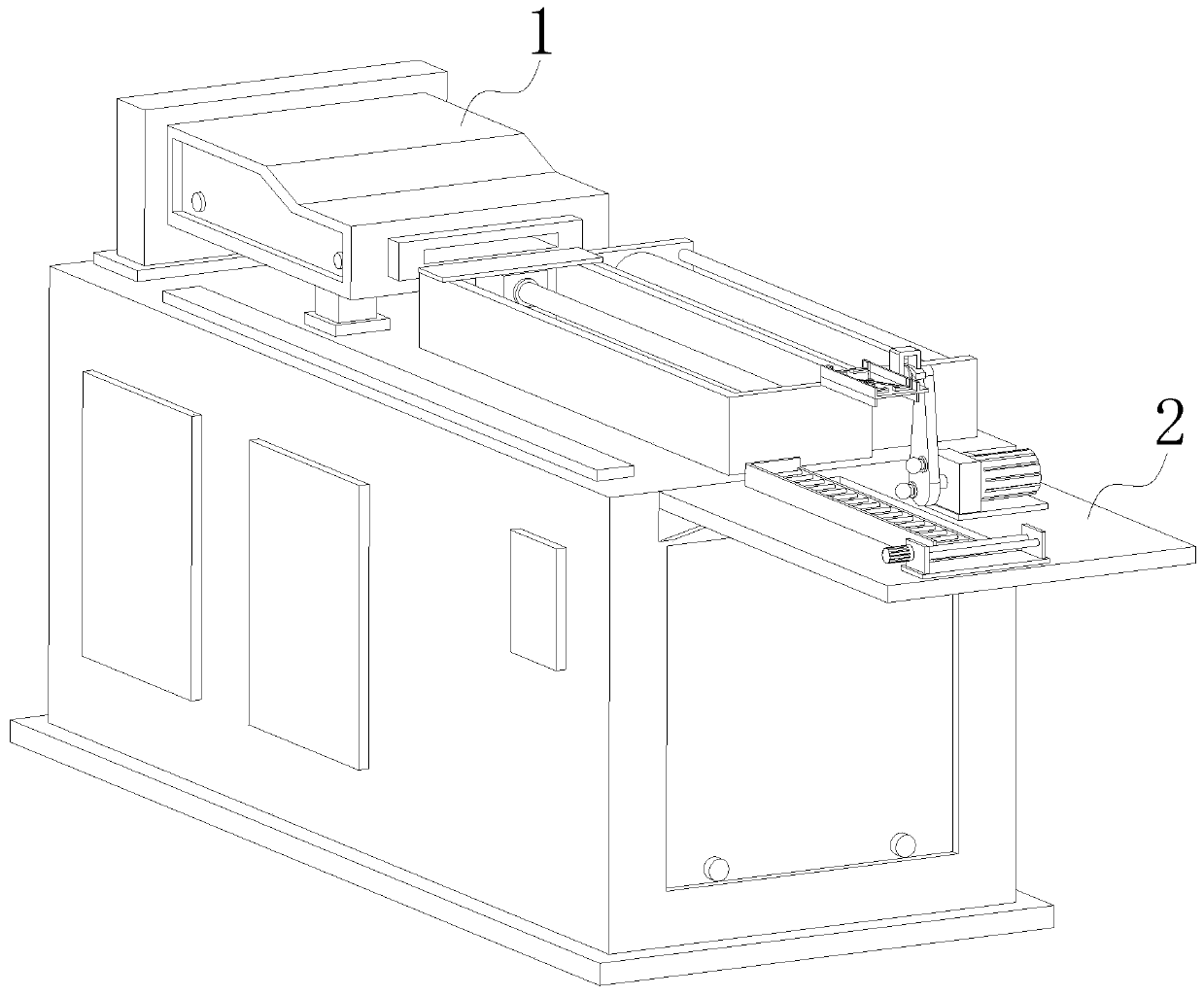

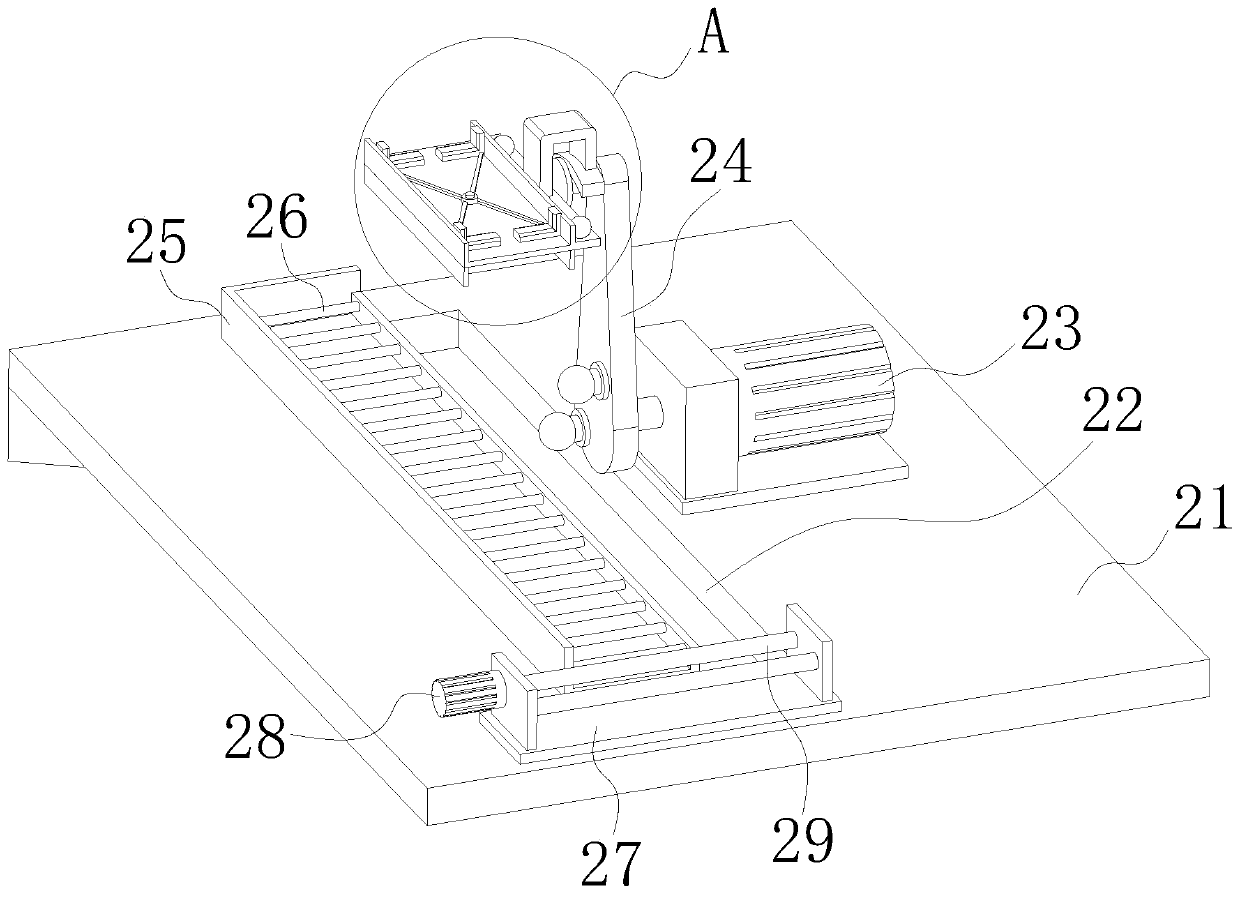

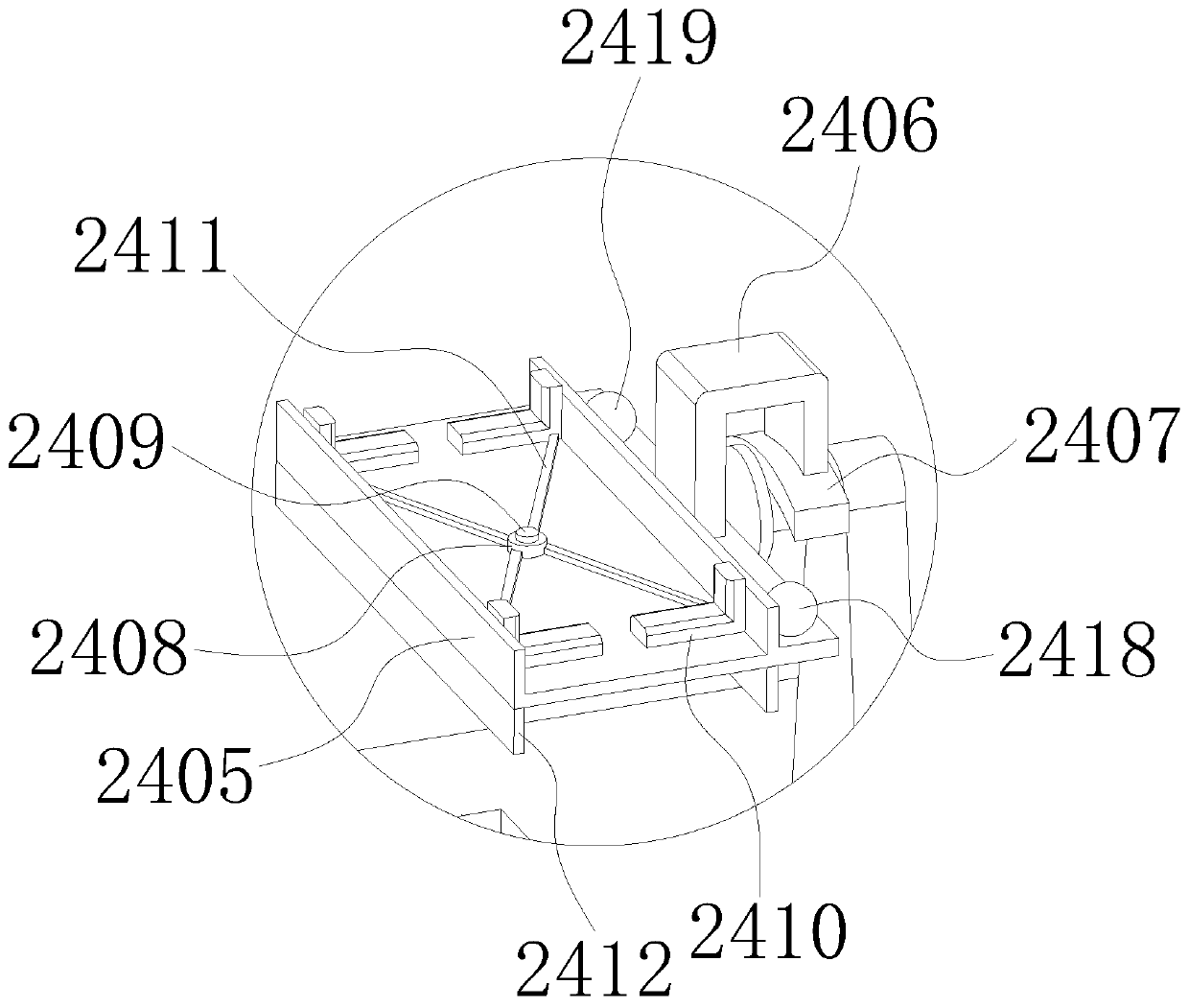

[0022] see Figure 1-6 , the present invention provides a technical solution: a rolling type blanking idler device for a low-wear copper bar hydraulic drawing machine, including a drawing machine body 1 and a blanking device 2, and the blanking device 2 is fixedly installed on the drawing machine The position of the discharge port of the main body 1, the unloading device 2 includes a plate body 21, a through groove 22, a drive motor 23, a supporting mechanism 24, a semi-closed frame 25, a rotating roller 26, a mounting frame 27, a small motor 28 and a discharge The roller 29, the left side of the plate body 21 is fixedly connected to the top of the right side of the drawing machine body 1, the through groove 22 is opened in the middle of the top of the plate body 21 and runs through the bottom of the plate body 21, and the output shaft is fixed to the drive motor 23 facing the front. Installed on the top of the plate body 21 and located at the rear side of the through groove 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com