Conveying mechanism realizing adjustable material conveying function

A technology for conveying materials and conveying mechanisms, which is applied in the field of logistics equipment, and can solve problems such as inability to centrally convey goods, limited effect, and limited conveying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

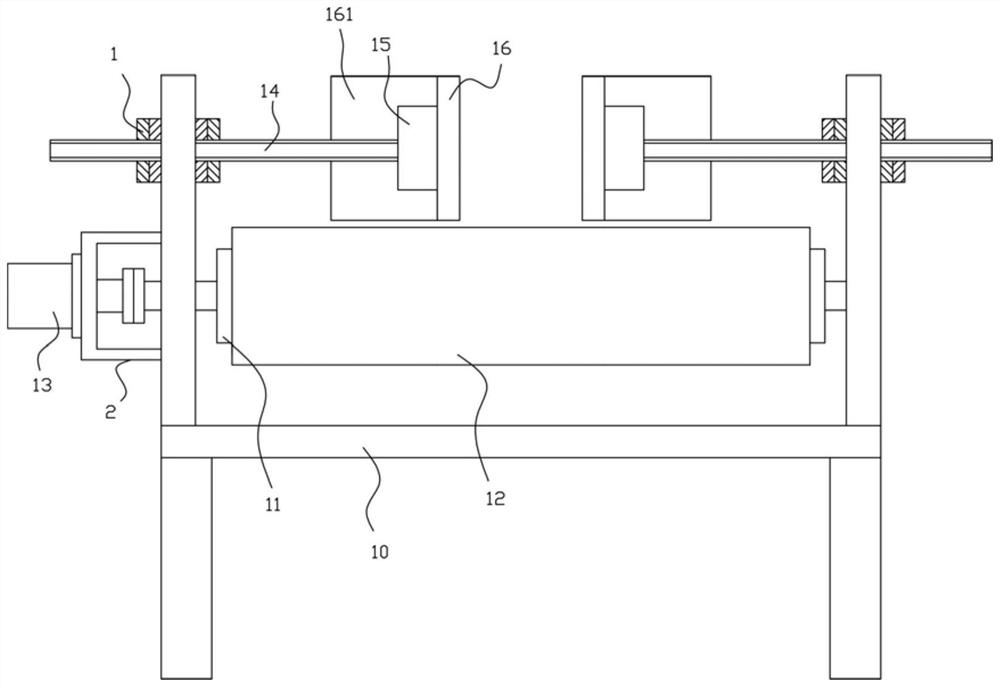

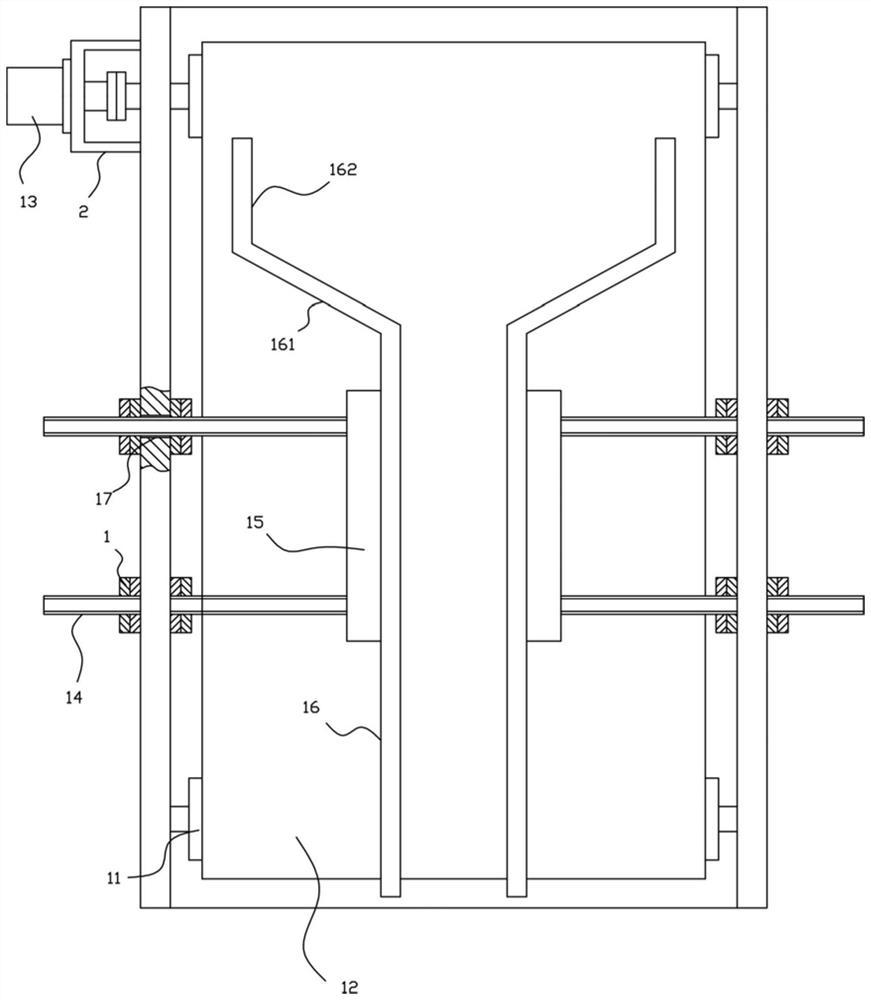

[0017] Examples, see e.g. Figures 1 to 2 As shown, a conveying mechanism with adjustable conveying materials includes a main frame body 10, and transmission rollers 11 are provided at the front and rear of the two side plates of the main frame body 10, and the two sides of the transmission rollers 11 The end connecting shaft is hinged on the two side plates through bearings;

[0018] A conveyor belt 12 is tensioned on the two drive rollers 11;

[0019] A drive motor 13 is fixed on the outer wall of one end of a side plate of the main frame body 10, and the drive motor 13 drives one of the drive rollers 11 to rotate;

[0020] The upper parts of the left and right side plates of the main frame body 10 are fitted with two adjusting screw rods 14, and the adjusting screw rods 14 are installed on the corresponding side plates. On the opposite wall surfaces of the two connecting blocks 15, side guide plates 16 are fixed, and the rear parts of the two side guide plates 16 are form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com