A special semi-conductive weft-free tape for transformer binding and its preparation method

A semi-conductive, weft-free technology, which is applied in the field of composite insulating materials, can solve the problems of partial discharge, high resistance of weft-free tape, and elevated working temperature of transformer oil, so as to reduce partial discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

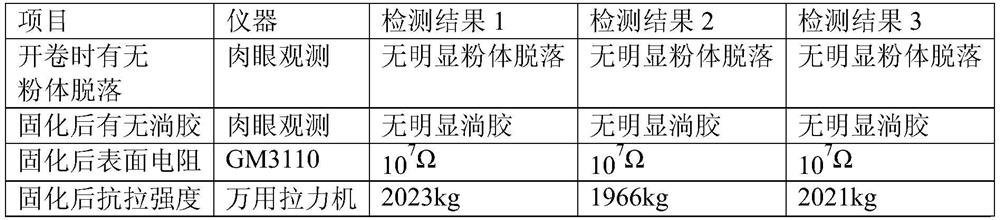

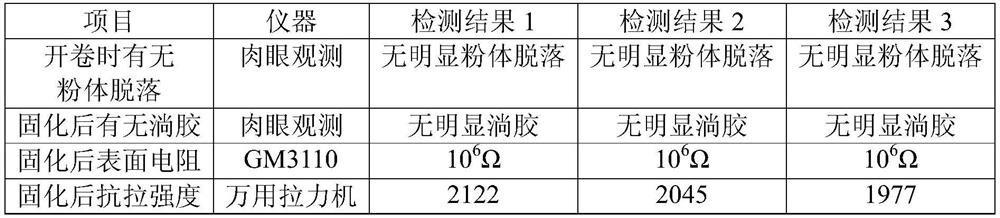

Embodiment 1

[0033] Embodiment 1 solvent-containing method

[0034] The formula ratio by weight is as follows:

[0035] 100 parts of unsaturated polyester resin; 0.2 parts of benzoyl peroxide; 2.0 parts of di-tert-butyl peroxide; 2.7 parts of metal copper powder; 6.3 parts of graphite powder; 2.1 parts of metal nickel powder; 4.8 parts of silicon carbide powder; 2 parts of calcium carbonate; 1 part of kaolin; 0.3 parts of fumed silica; 3.4 parts of styrene; 22 parts of diallyl phthalate; 3 parts of zinc stearate; 40 parts of acetone.

[0036] Concrete reaction process is as follows:

[0037] (1) Mixing: put 100 parts of unsaturated polyester, 22 parts of diallyl phthalate, and 40 parts of acetone into the reaction kettle and heat up to 40°C to dissolve, keep warm; put in 4.8 parts of silicon carbide powder and 2.1 parts of metal nickel powder in turn. Parts, 2.7 parts of metal copper powder, 6.3 parts of graphite powder, 1 part of kaolin, 0.3 parts of fumed silica, 2 parts of light calci...

Embodiment 2

[0054] Embodiment 2 solvent-containing method

[0055] The formula ratio by weight is as follows:

[0056] 100 parts of unsaturated polyester resin; 0.3 parts of benzoyl peroxide; 1.9 parts of di-tert-butyl peroxide; 2.7 parts of metal copper powder; 8.7 parts of graphite powder; 2.6 parts of metal nickel powder; 5.5 parts of silicon carbide powder; 1.8 parts of calcium carbonate; 1.5 parts of kaolin; 0.5 parts of fumed silica; 4 parts of styrene; 25 parts of diallyl phthalate; 2.2 parts of zinc stearate; 50 parts of acetone.

[0057] Concrete reaction process is as follows:

[0058] (1) Mixing: Put 100 parts of unsaturated polyester, 25 parts of diallyl phthalate, and 50 parts of acetone into the reaction kettle and heat up to 40°C to dissolve and keep warm; put in 5.5 parts of silicon carbide powder and 2.6 parts of metal nickel powder in turn. Parts, 2.7 parts of metal copper powder, 8.7 parts of graphite powder, 1.5 parts of kaolin, 0.5 parts of fumed silica, 1.8 parts o...

Embodiment 3

[0067] Embodiment 3 solvent-free method

[0068] The formula ratio by weight is as follows:

[0069] 100 parts of unsaturated polyester resin; 0.1 parts of benzoyl peroxide; 2.3 parts of di-tert-butyl peroxide; 1.7 parts of metal copper powder; 5.1 parts of graphite powder; 1.3 parts of metal nickel powder; 4.1 parts of silicon carbide powder; 1.3 parts of calcium carbonate; 1.2 parts of kaolin; 0.1 parts of fumed silica; 3.1 parts of styrene; 26 parts of diallyl phthalate; 2.1 parts of zinc stearate.

[0070] (1) Mixing: Take 100 parts of unsaturated polyester and 26 parts of diallyl phthalate, put them into the reactor and heat up to 75°C to melt, keep warm; put in 4.1 parts of silicon carbide powder, 1.3 parts of metal nickel powder, metal 1.7 parts of copper powder, 5.1 parts of graphite powder, 1.2 parts of kaolin, 0.1 part of fumed silica, 1.3 parts of light calcium carbonate, 2.1 parts of zinc stearate; Stir at 75°C with a speed of 60r / min for 40min;

[0071] (2) Feed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com