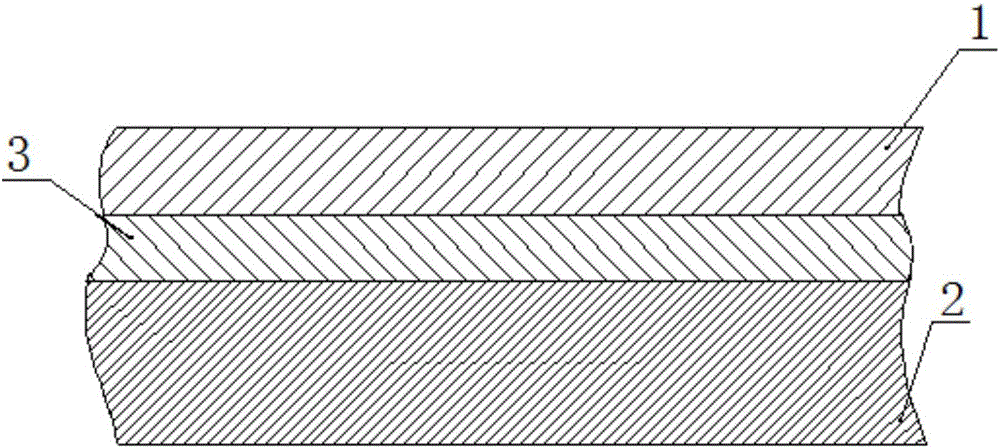

Semi-conductive buffering tape for sea cables

A semi-conductive, buffer tape technology, used in power cables, cables, circuits with shielding/conducting layers, etc., can solve the problem that the tape cannot meet its requirements, etc., and achieve low product resistance, weakening electric field strength, and increasing firmness. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

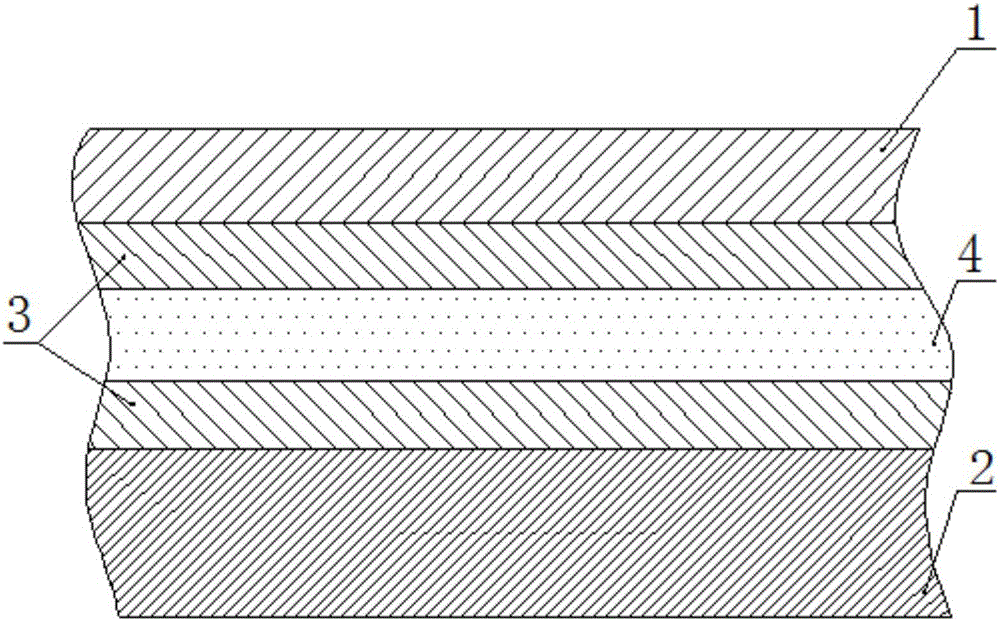

Embodiment 1

[0045] The hot-rolled cloth and fluffy needle-punched cotton are impregnated with semi-conductive glue through production equipment. The surface resistance of the obtained semi-conductive hot-rolled cloth is 860Ω, and the surface resistance of the semi-conductive fluffy needle-punched cotton is 500Ω. One side of the cloth and the semi-conductive fluffy needle-punched cotton is sprayed with adhesive, and the adhesive powder is sprayed on the adhesive of the semi-conductive hot-rolled cloth, and then the two semi-conductive non-woven fabrics are compounded, extruded and dried to obtain the Conductive buffer tape.

[0046] The thickness of the prepared semi-conductive buffer tape is 2.1mm, and the weight per unit area is 270g / m 2 , surface resistance 350Ω, volume resistivity 3.1×10 3 Ω·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com