Semi-conductive heat-conducting block for frozen soil subgrade, preparation method and laying method thereof

A technology for building blocks and roadbeds, applied in the field of semi-conductive blocks for frozen soil roadbeds and their preparation, can solve problems such as high consumption and increase in materials, achieve uniform heating, reduce thermal expansion and cold contraction, and improve stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

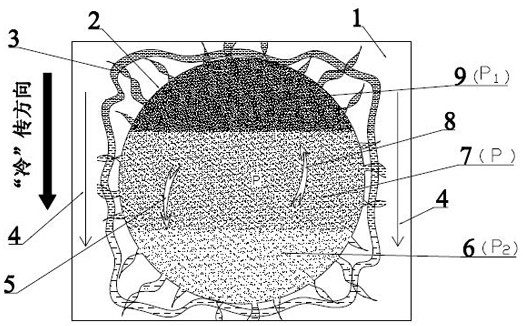

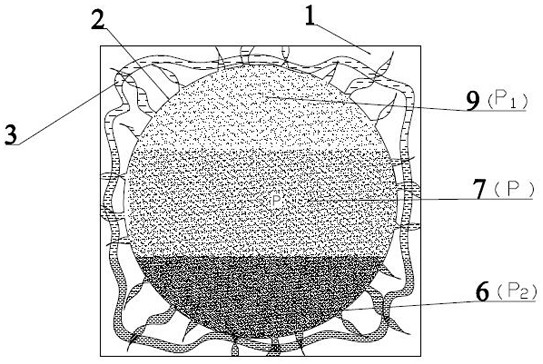

[0039] A method for preparing a semi-thermally conductive block for a frozen soil subgrade, comprising the following preparation steps:

[0040] Step 1, utilizing block raw materials including cement, sand, silica fume, water and concrete foaming agent to prepare foamed concrete blocks;

[0041] Step 2. Place the cured test block in a closed space equipped with a pipeline for injecting metering liquid, heat it to 80~85°C and pump air to a pressure below 3kPa, and the pressure does not increase significantly after 10 seconds after stopping the pumping , that is, under the condition of not pumping air but keeping warm at 80~85°C, add 95% ethanol through a meterable pipeline, so that the volume ratio of absolute ethanol to free water in the test block is not less than 4, and continue to keep warm for more than 24 hours. Take out the ethanol after it is evenly distributed inside the block.

[0042] Further, after taking out the block to which ethanol was added in step 2, thermall...

specific Embodiment

[0053] A method for preparing a semi-thermally conductive block for a frozen soil subgrade, specifically comprising the following preparation steps:

[0054] Step 1. Take water and methylvinyldiethoxysilane (internal waterproofing agent, referred to as "silane") to mix and stir. After stirring evenly, add cement, fine sand, silica fume, and stir well to obtain slurry. Cement: fine The mass ratio of sand: silica fume: silane is (30~40): (50~65): (4~6): (0.3~0.7);

[0055] Step 2. Add the foam produced by diluting and foaming the foaming agent into the slurry obtained in step 1. After stirring evenly, pour it into the mold and scrape it flat;

[0056] Step 3. After demoulding, get the test block, place the test block in the curing box, and cure it at 25°C for 28~40 days. ≤4%;

[0057] Step 4. According to the "Construction Industry Standards of the People's Republic of China (JG / T-266-2011)", take 6 pieces and measure the "dry density, water absorption and compressive strength...

Embodiment 1

[0062] The formula of embodiment 1 block is as shown in table 1. During the production of blocks, the ingredients are produced according to the weight percentage. The test block takes 16L raw materials according to the weight, and makes 15 test blocks of 10×10×10cm. The 1L material is used as a room for adjustment and container contamination loss.

[0063] Table 1 Example 1 Frozen Soil Subgrade Block Formula 1 (total volume of materials used: 16L)

[0064]

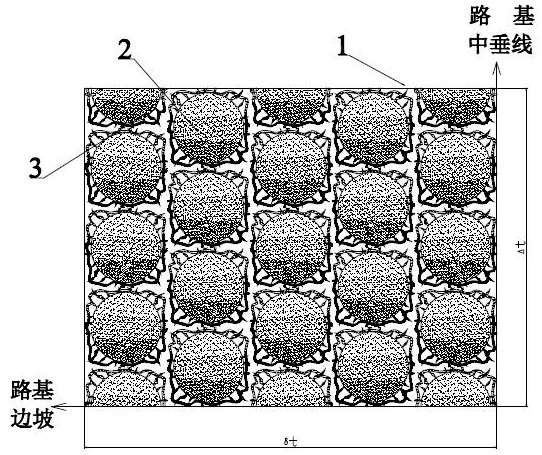

[0065] Test block preparation and laying

[0066] 1. Take a stainless steel cylinder with a diameter of 36.8cm and a depth of 37cm, make a ruler and draw a mark 20cm away from its A end, hold the B end so that AB coincides with the busbar on the inner wall of the cylinder. When aligned, the volume from the plane shown at end A to the bottom of the barrel is the target volume of foam concrete foam slurry, and its volume is 16 L.

[0067] 2. Add 3652.5g of tap water and 70.3g of silane to the stainless steel drum descri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com