Spring bolt mechanism and lock

A lock tongue and moving plate technology, applied in the field of locks, can solve problems such as high resistance of the lock tongue structure, and achieve the effect of saving effort in unlocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

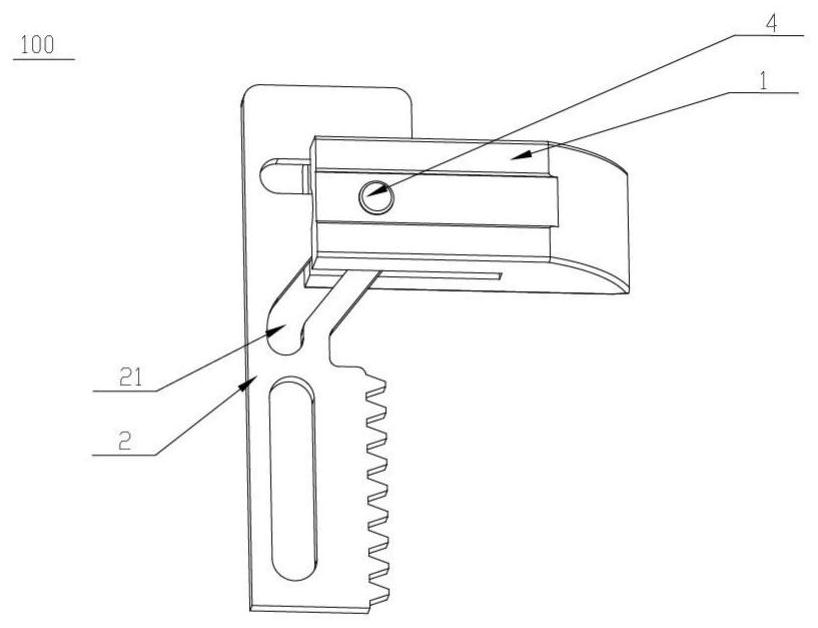

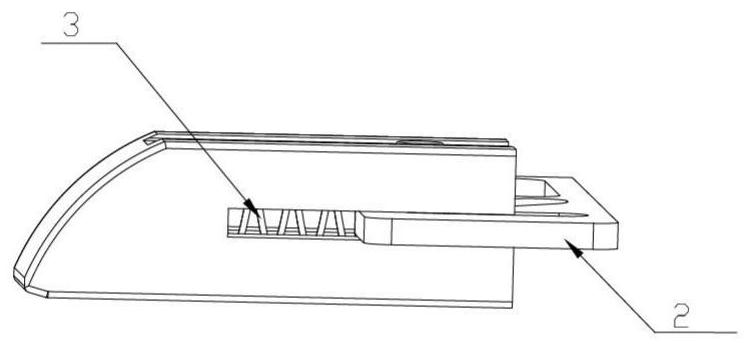

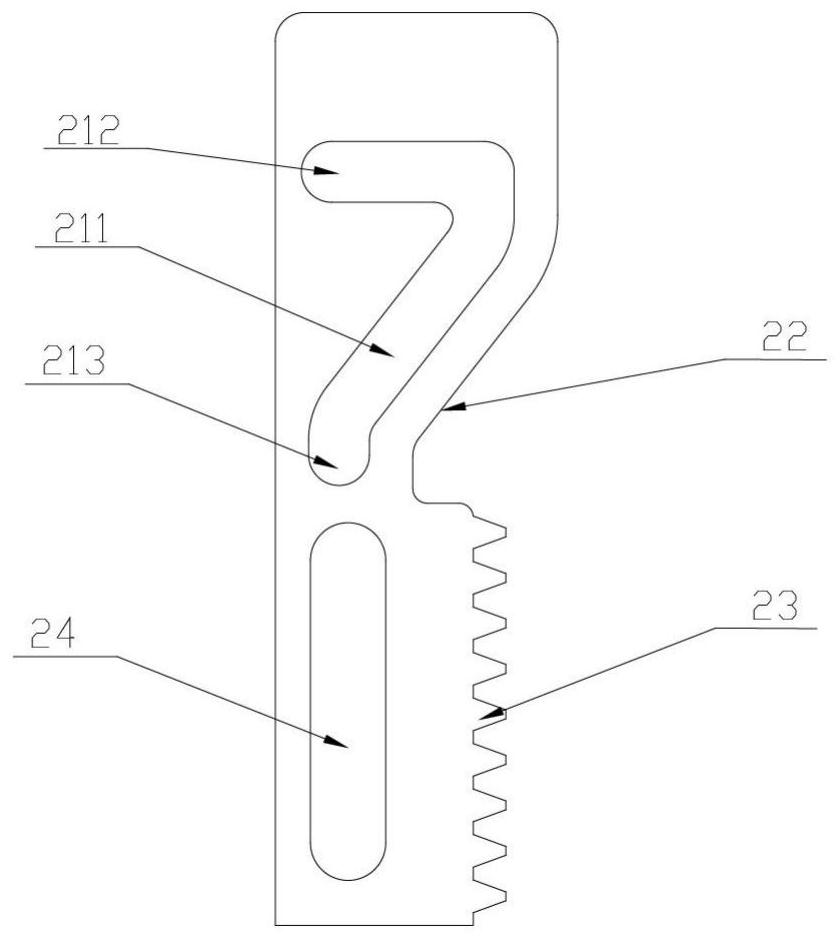

[0022] The preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0023] like Figure 1 to Figure 3 As shown, the deadbolt mechanism 100 of the present invention includes a deadbolt 1, a moving plate 2 and an elastic member 3. The locking tongue 1 can be telescopically moved, and a limiting member 4 is arranged on it. The moving plate 2 is provided with a sliding groove 21 , and the sliding groove 21 includes a first groove segment 211 inclined relative to the moving direction of the lock tongue 1 . The limiter 4 is inserted in the chute 21 to realize the linkage between the lock tongue 1 and the moving plate 2 . One side surface of the moving plate 2 is provided with a guiding inclined surface 22 which is parallel to the first groove section 211 or forms a small angle with the first groove section 211 . One end of the elastic member 3 is connected with the locking tongue 1 , and the other end is abutted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com