A rough button engraving, rendering, and old processing equipment

A technology for processing equipment and buttons, applied to buttons, fasteners, special decorative structures, etc., can solve the problems of inconvenient hand-held rough buttons, lower product quality of rough buttons, and uneven rendering and smearing of rough button surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

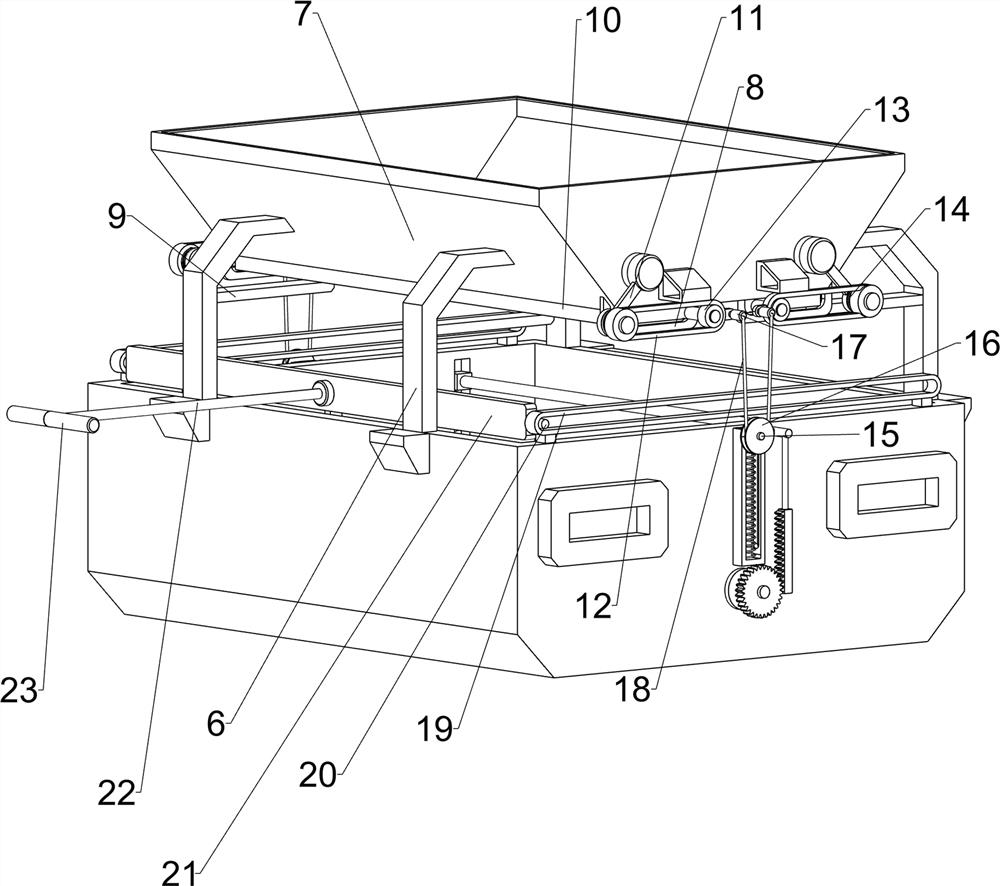

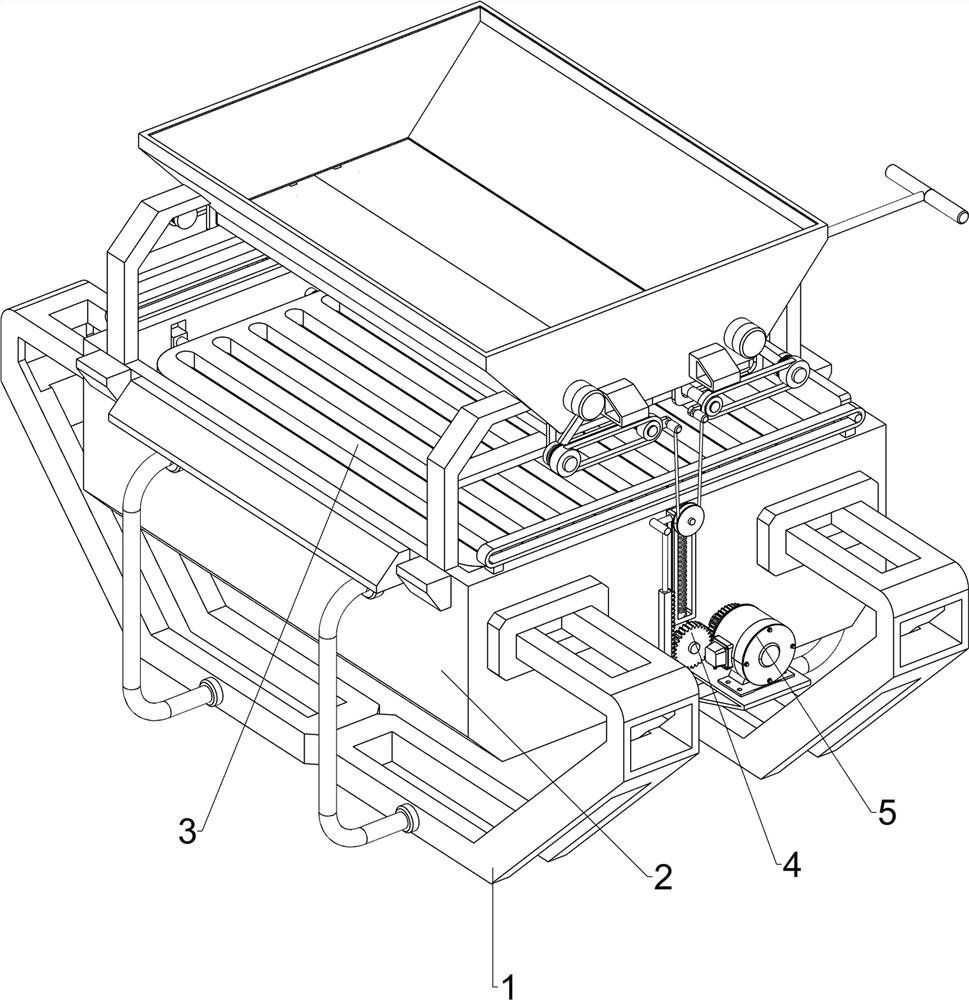

[0023] like figure 1 , figure 2 and image 3 As shown in the figure, a blank button engraving, rendering and old processing equipment includes a base 1, a rendering pool 2, a lifting mechanism 3, a rendering mechanism 4 and a driving mechanism 5. The top of the base 1 is provided with a rendering pool 2, and the rendering pool 2 is provided with a Lifting mechanism 3, a rendering mechanism 4 is arranged between the rendering pool 2 and the lifting mechanism 3, and a driving mechanism 5 is arranged on the front side of the rendering pool 2.

[0024] The lifting mechanism 3 includes a first sliding block 32, a first round rod 33, a filter plate 34 and a first elastic member 35. The front and rear side walls of the rendering pool 2 are symmetrically provided with a first chute 31. The first chute 31 is slidably provided with a first slider 32, a first round bar 33 is arranged on the first slider 32, a filter plate 34 is arranged between the four first round bars 33, and the fi...

Embodiment 2

[0029] like Figure 4 As shown, on the basis of Embodiment 1, a blank button engraving rendering and old processing equipment also includes an installation rod 6, a lower hopper 7, a U-shaped rod 8, a second slide rail 9 and an opening and closing plate 10. The rendering pool 2. The four corners of the top are provided with installation rods 6, the tops of the four installation rods 6 are provided with a lower hopper 7, the four corners of the lower side of the lower hopper 7 are provided with U-shaped rods 8, and the upper side of the installation rod 6 is provided with a second slide rail 9 The opening and closing plate 10 is slidably arranged between the second slide rails 9 on the same side.

[0030] When the worker needs to carry out the engraving, rendering and old processing of the blank button, the worker pours the blank button into the lower hopper 7, and pulls the two opening and closing plates 10 to move back between the second slide rail 9 and the U-shaped rod 8 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com