Mechanical equipment energy consumption anomaly detection method based on mechanism data fusion

A technology of mechanical equipment and data fusion, applied in the field of mechanical inspection and machinery, it can solve the problems of poor generalization ability of general mechanical equipment, and achieve the effect of reducing complexity and analysis cost, low collection difficulty, and reducing types and quantities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

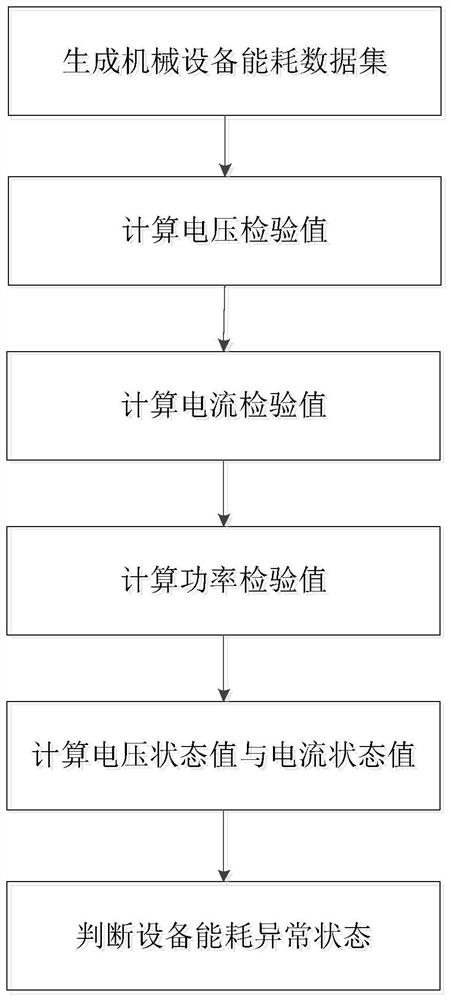

[0034] refer to figure 1 , to further describe in detail the specific implementation steps of the present invention.

[0035] Step 1, generate the energy consumption data set of the mechanical equipment to be tested.

[0036] The first step is to collect the three-phase voltage and three-phase current data of the equipment to be tested for 5000 seconds at a data collection time interval of 5s from the running time of the mechanical equipment to be tested, and collect 1000 voltages and 1000 currents The data constitute the voltage and current data sets of the mechanical equipment to be detected.

[0037] In the second step, use the same method as the first step of this step to generate the power data set of the mechanical equipment to be tested.

[0038] Step 2, using the mechanism data fusion method to calculate the test value of the voltage in the voltage data set.

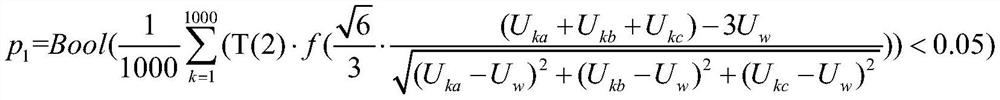

[0039] Calculate the abnormal test value of the voltage under the standard T test according to the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com