Seat frame mounting structure

An installation structure and seat frame technology, applied in the direction of movable seats, etc., can solve the problems of increasing cost, increasing the length of the rear panel of the seat frame, insufficient foot space, etc., so as to increase foot space, strengthen support, reduce The effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

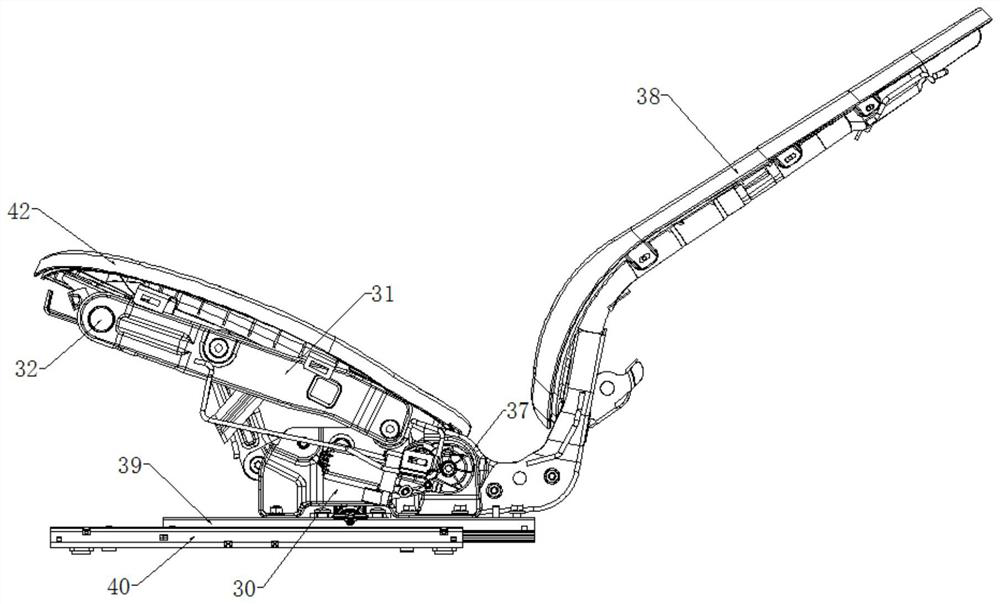

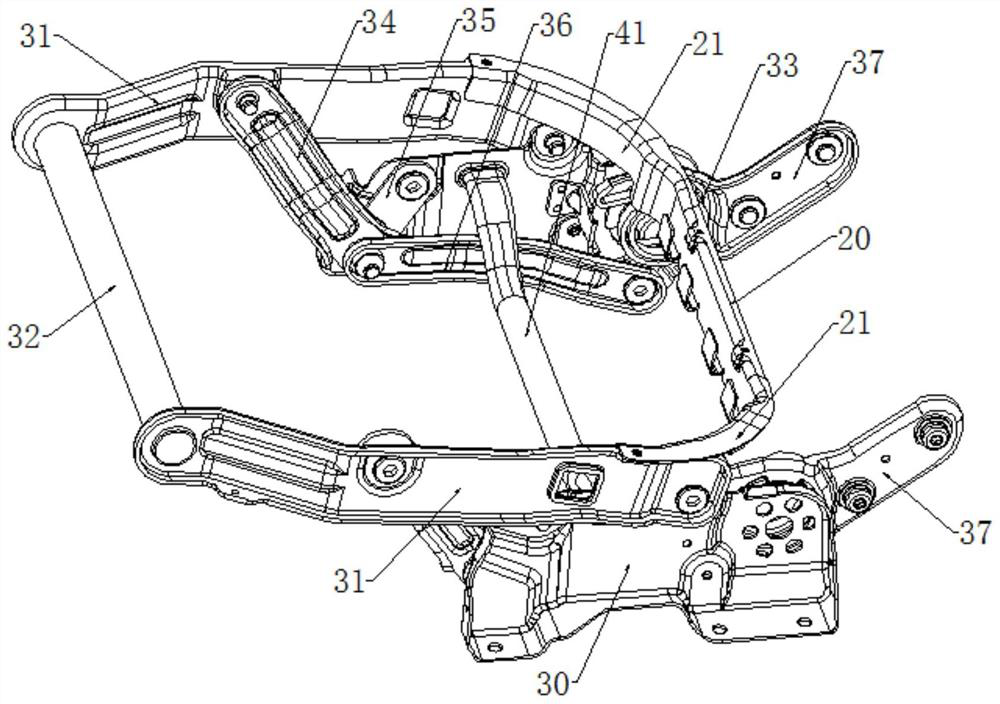

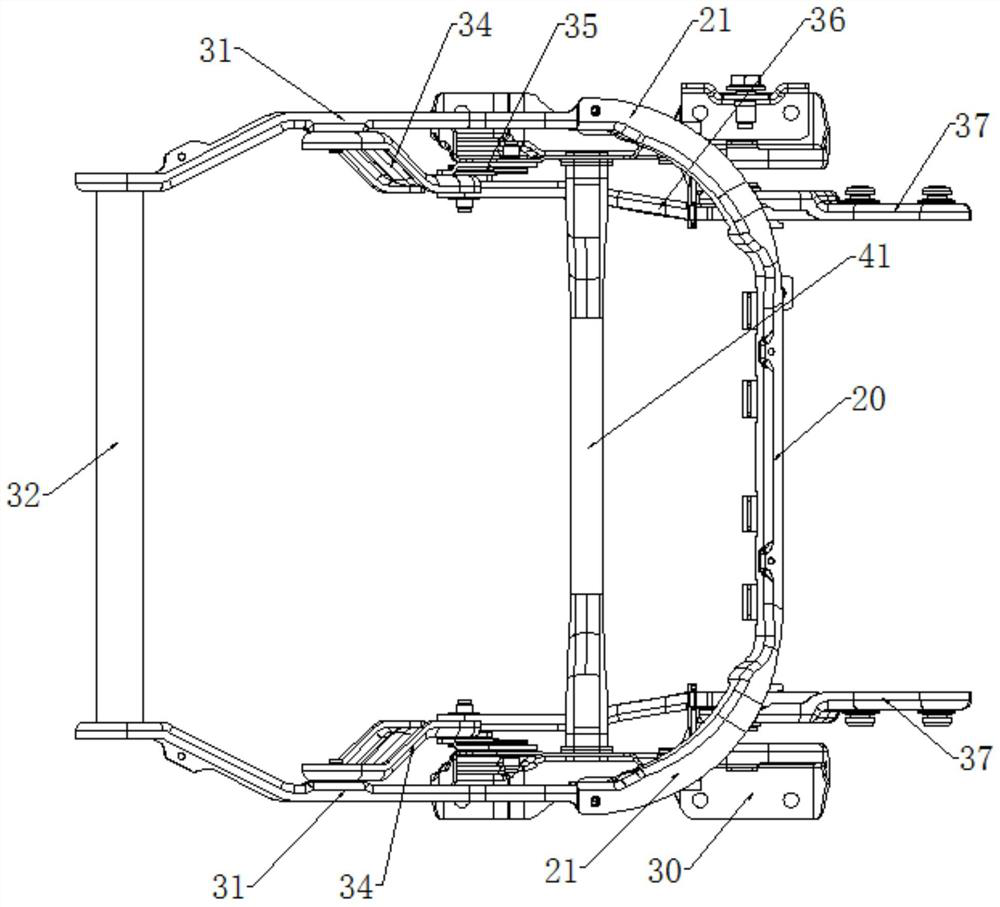

[0048] Such as Figure 1 to Figure 12 As shown, a seat frame installation structure, which mainly includes a seat frame body, a lower connector and a slide rail, is characterized in that: the slide rail is arranged horizontally, the lower connector is installed on the upper surface of the slide rail, The lower connecting piece is located below the seat frame body, and the seat frame body is installed on the slide rail through the lower connecting piece;

[0049] The lower connecting piece includes two recliner lower connecting plates 30 facing oppositely. The main body is connected, and the lower part of the lower connecting plate 30 of the recliner is fixedly connected with the slide rail.

[0050] in:

[0051] The rear part of the seat frame body is connected to the lower connecting plate 30 of the recliner, and the front part of the seat frame body is s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap