Brake master cylinder assembly, electronic hydraulic brake system and motor vehicle

A brake master cylinder and hydraulic brake technology, which is applied in the direction of brake transmission, brakes, vehicle components, etc., can solve problems such as brake failure, master cylinder push rod collapse, false triggering, etc., to increase the size of the foot space, damage reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

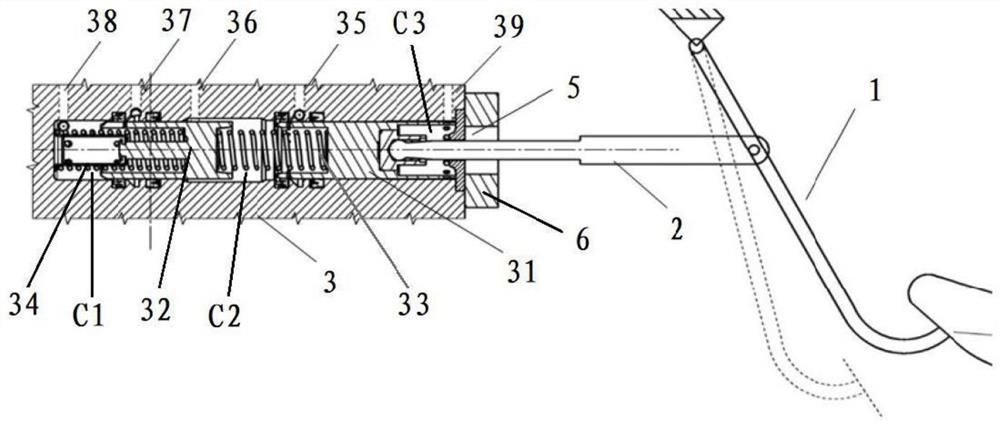

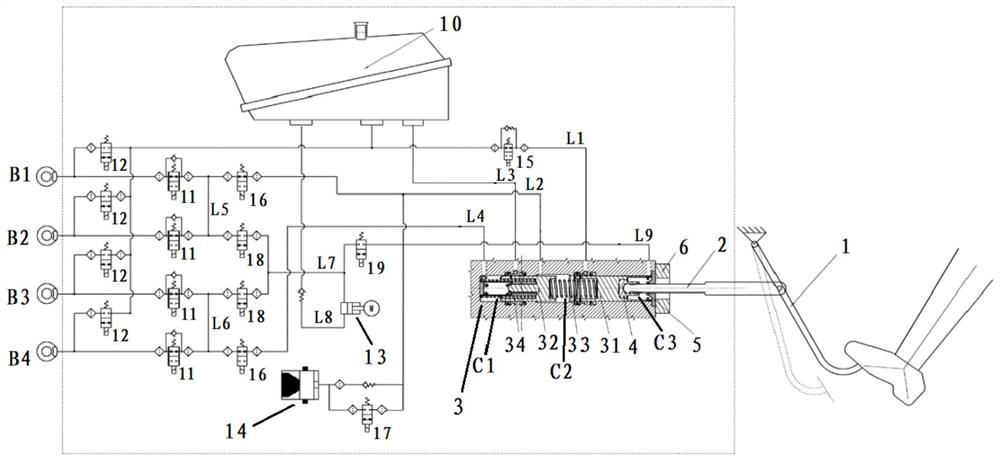

[0022] figure 1 A schematic diagram of a brake master cylinder assembly according to an embodiment of the present invention is shown. like figure 1 As shown, the brake master cylinder assembly of this embodiment includes a push rod 2 and a brake master cylinder 3 . The first end of the push rod 2 is fixedly connected with the brake pedal 1 . The second end of the push rod 2 is fixedly connected with the piston of the brake master cylinder 3 . In the illustrated embodiment, the brake master cylinder 3 has two successively arranged first pistons 31 and second pistons 32 in the housing, and the second end of the push rod 2 can pass through the pressure block 4 (see figure 2 ) is fixedly connected with the first end of the first piston 31. A first hydraulic chamber C1 is defined between the first piston 31 and the second piston 32 , and a second hydraulic chamber C2 is defined between the second piston 32 and the housing bottom of the master cylinder 3 . In addition, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com