Automobile seat

A car seat and seat frame technology, which is applied to vehicle seats, seat frames, movable seats, etc., can solve the problems of increasing the length of the rear panel of the seat frame, insufficient foot space, and increasing costs, and achieves simplification The installation structure, the structure is simple and effective, and the effect of increasing the foot space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

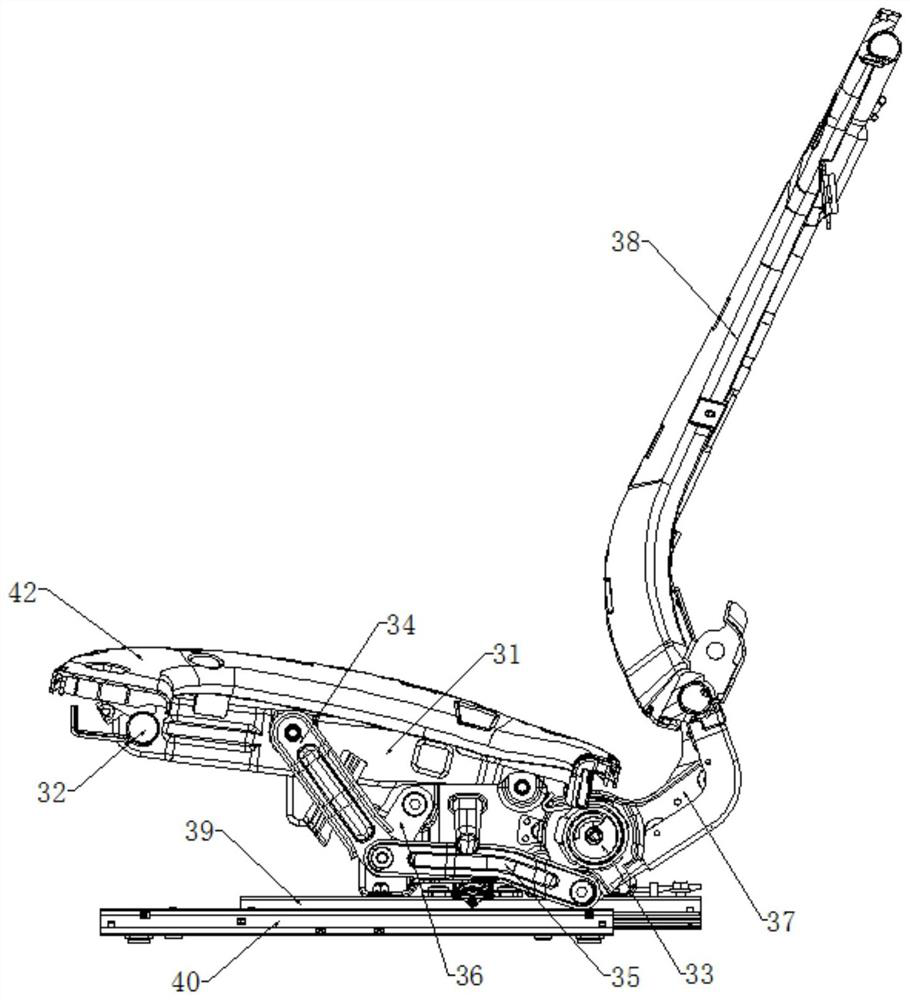

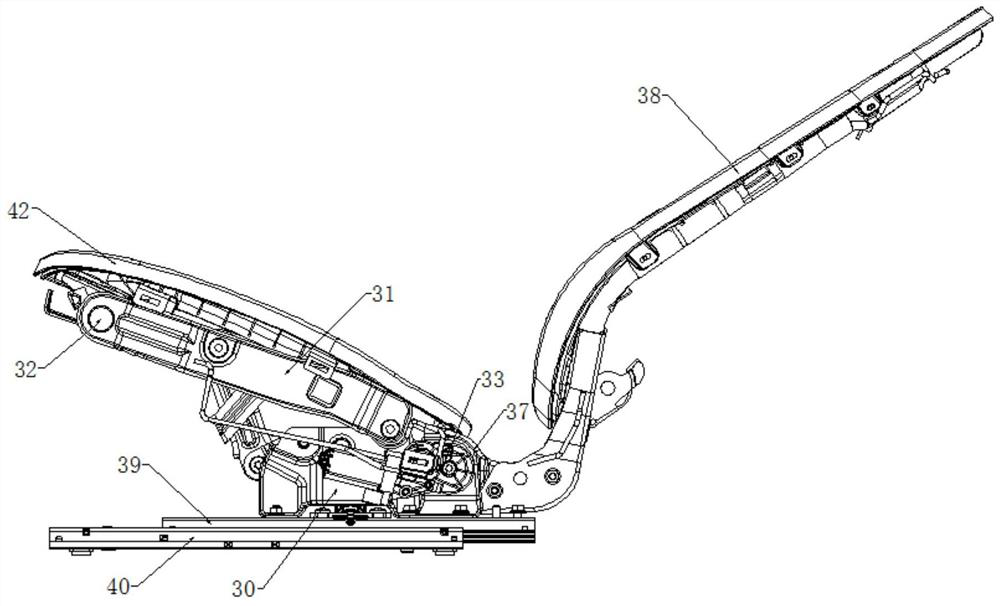

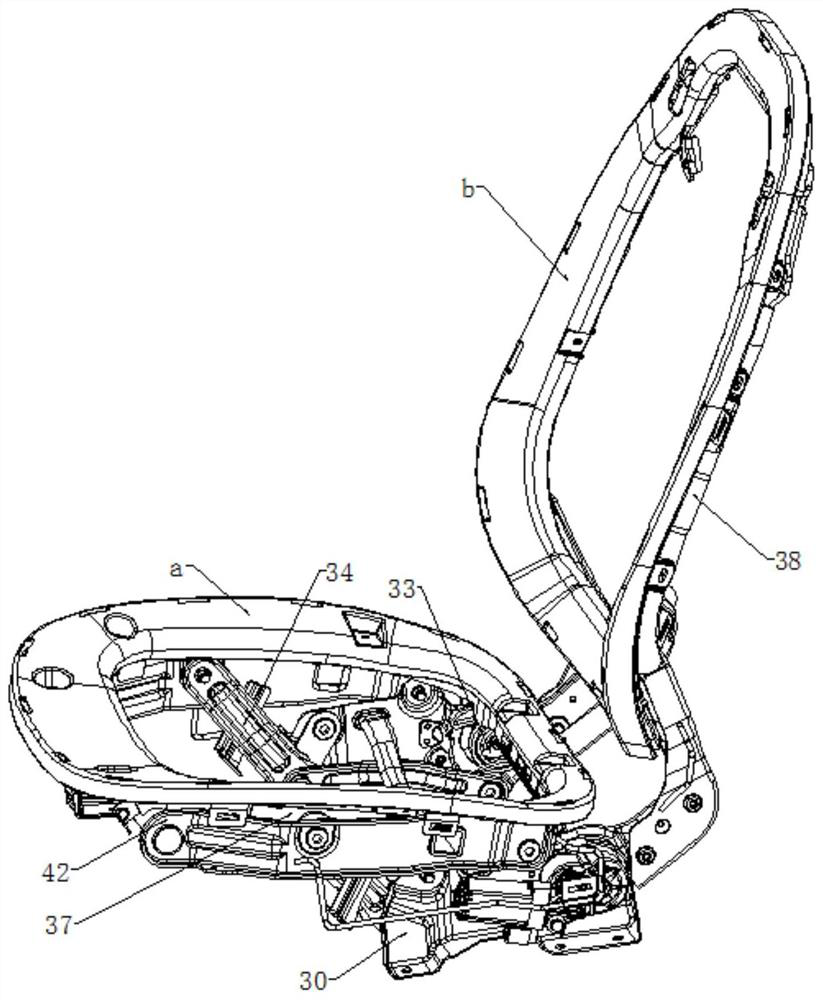

[0067] Such as Figure 1 to Figure 23 As shown, a car seat mainly includes an installation base, a seat cushion, a backrest, a linkage and a power unit, the rear part of the seat cushion and the lower part of the backrest are hinged to the installation base, and the The seat cushion and the backrest are connected through the linkage;

[0068] The installation base includes two sliding rails facing oppositely, and the upper surfaces of the sliding rails are respectively provided with mounting parts, and the power device is installed on any one of the mounting parts, and the power device drives the backrest rotation;

[0069] Described linkage comprises upper hinged rod 34, lower hinged rod 35 and connecting rod 36, and one end of described upper hinged rod 34 is hinged with the front portion of described seat frame 42, and the other end of described upper hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com