Oxidation air system control method based on data model and mechanism operation

A data model and control method technology, which is applied in chemical instruments and methods, program control, separation methods, etc., can solve the problems of large maintenance, high investment cost, and increased investment cost, so as to avoid cumulative errors, low investment cost, The effect of guaranteeing reasonableness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

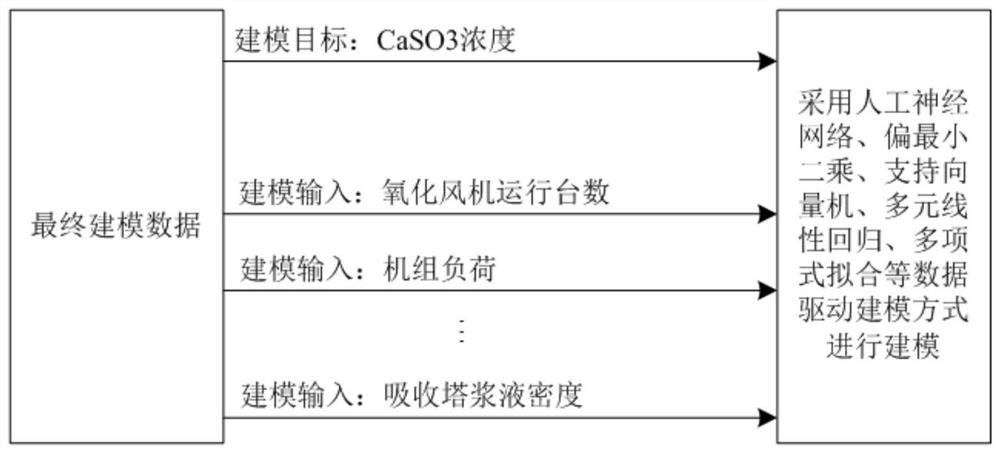

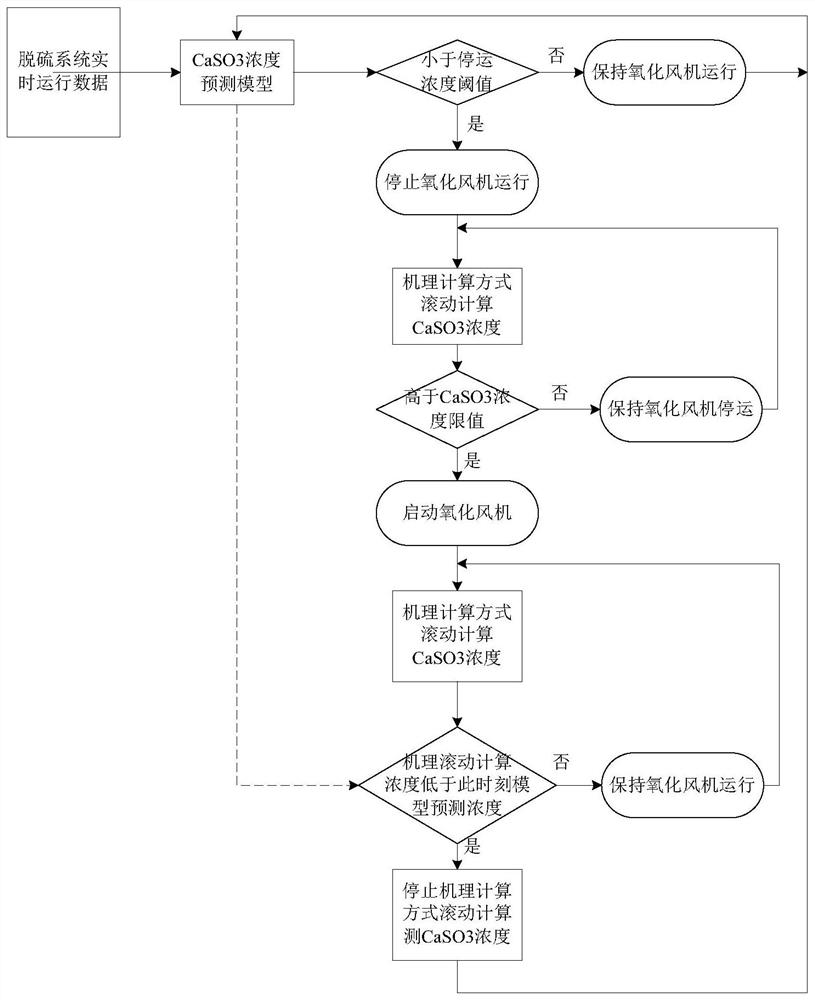

[0048] An embodiment of an oxidation wind system control method based on data models and mechanism calculations. The main principle of this method is: through the historical operation and test data of the unit, establish the absorption tower slurry CaSO 3 Concentration model by which to predict absorber CaSO 3 Concentration, the deviation between the concentration and the maximum allowable concentration is used as the basis for judging whether the oxidation fan is out of operation. When the difference between the maximum allowable concentration and the predicted concentration is greater than the outage threshold, the oxidation fan is stopped. After the oxidation fan is out of operation, it is added synchronously Mechanism calculation method to estimate CaSO per unit time 3 Generated amount, and calculate the absorption tower slurry CaSO by rolling according to this value 3 Concentration, when calculating the resulting collection slurry CaSO 3 When the concentration rises to ...

Embodiment 2

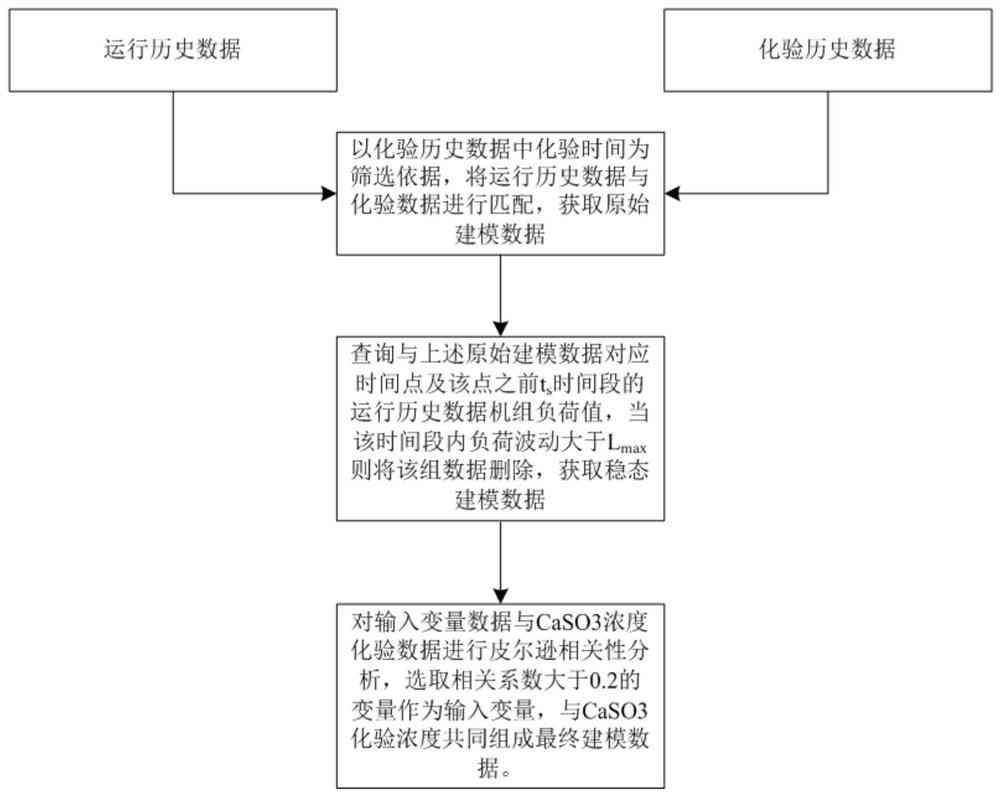

[0086] The oxidative wind system control method based on the data model and mechanism calculation of the above-mentioned embodiments of the present invention can also be improved as follows. When the modeling data is further screened for steady-state working conditions, the stable operating time of the load working conditions before and after the sampling time may not be The steady-state judgment basis can also use flue gas flow, FGD inlet sulfur content or flue gas flow multiplied by FGD inlet sulfur content and other variables before and after the sampling time for stable operation time as the steady-state judgment basis; the input variable data in the steady-state data with CaSO 3 Pearson correlation analysis was performed on the concentration test data, and variables with a correlation coefficient greater than 0.2 were selected as input variables, and the CaSO 3 The assay concentrations together constitute the final modeling data, and other correlation analysis methods and...

Embodiment 3

[0088] Net calcium sulfite content NG(k) in the absorption tower at the present moment: use the net calcium sulfite mass SQ(k) in the absorption tower at the present moment and the net by-product mass BQ(k) in the absorption tower to calculate the net calcium sulfite content in the absorption tower at the present moment, It should be noted that CaSO 3 The concentration is not a negative value, and when the test value AS(k) is input, the test value is assigned to NG(k) to participate in the next cycle. When there is no test value input, the calculation method can be expressed as:

[0089] NG(k)=(SQ(k)+abs(SQ(k))) / 2 / BQ(k);

[0090] When the test value AS(k) is input, its calculation method is:

[0091] NG(k)=AS(k);

[0092] Among them, the data can also be corrected through the online learning link design, specifically,

[0093] By predicting CaSO 3 Concentration and Assay CaSO 3 The concentration deviation corrects variables such as the system's forced oxidation rate and n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com