A high-voltage DC optical fiber power composite submarine cable

A high-voltage direct current, optical fiber technology, applied in the field of power cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

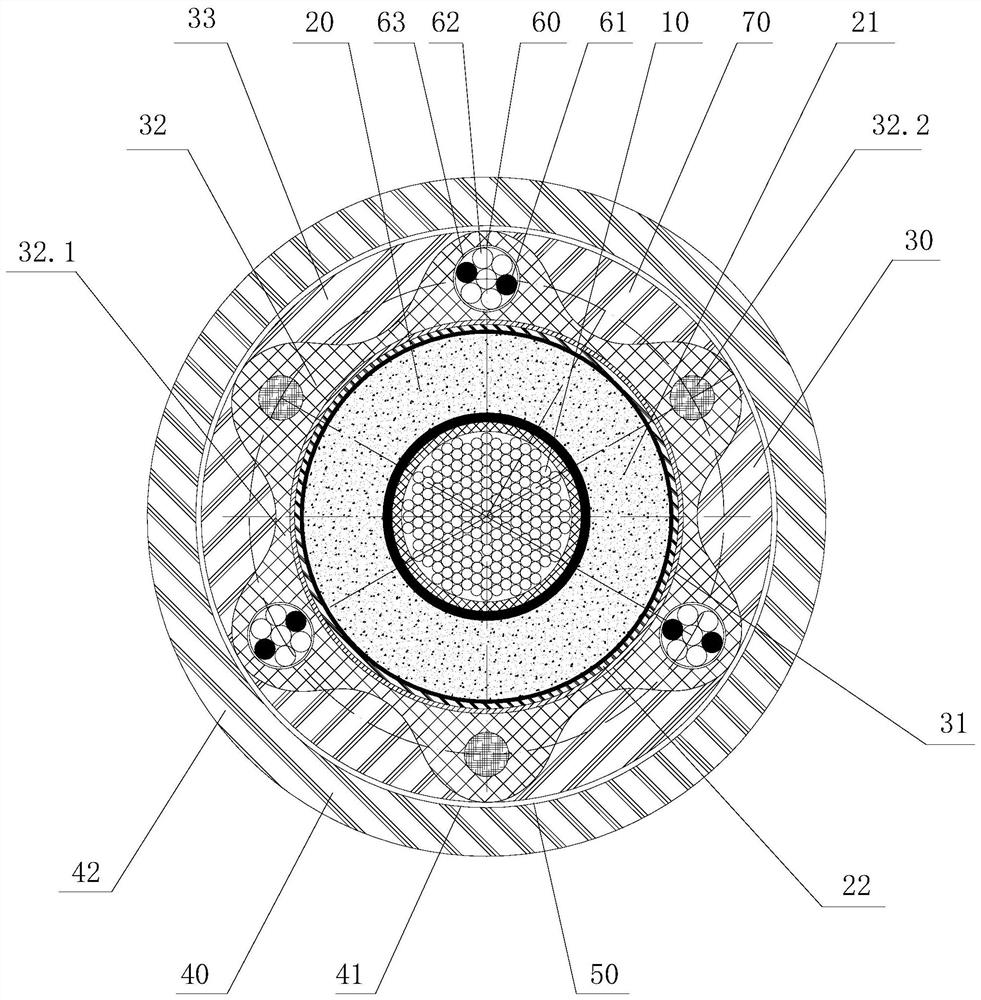

[0042] A high-voltage direct current optical fiber power composite submarine cable, the composite cable is an extension body extending along the central axis A with a cross section, the cross section is circular, rectangular or square; it includes conductor core units arranged in sequence from the inside to the outside 10. Insulation filler unit 20 , compound extruded unit 30 , and armored sheath unit 40 .

[0043]The conductor core unit 10 includes a circular compressed conductor 11 with a built-in water blocking tape 12 , and a conductor shielding layer 15 is provided outside the circular compressed conductor 11 . The circular compacted conductor 11 is formed by compressing a central circular conductor 13 and a plurality of tile-shaped conductors 14 layer by layer with wave-type twisted water-blocking tapes 12, the conductor filling factor is greater than or equal to 95%, and the effective cross-section of the conductor after compacting is greater than 90mm 2 . The water-b...

Embodiment 2

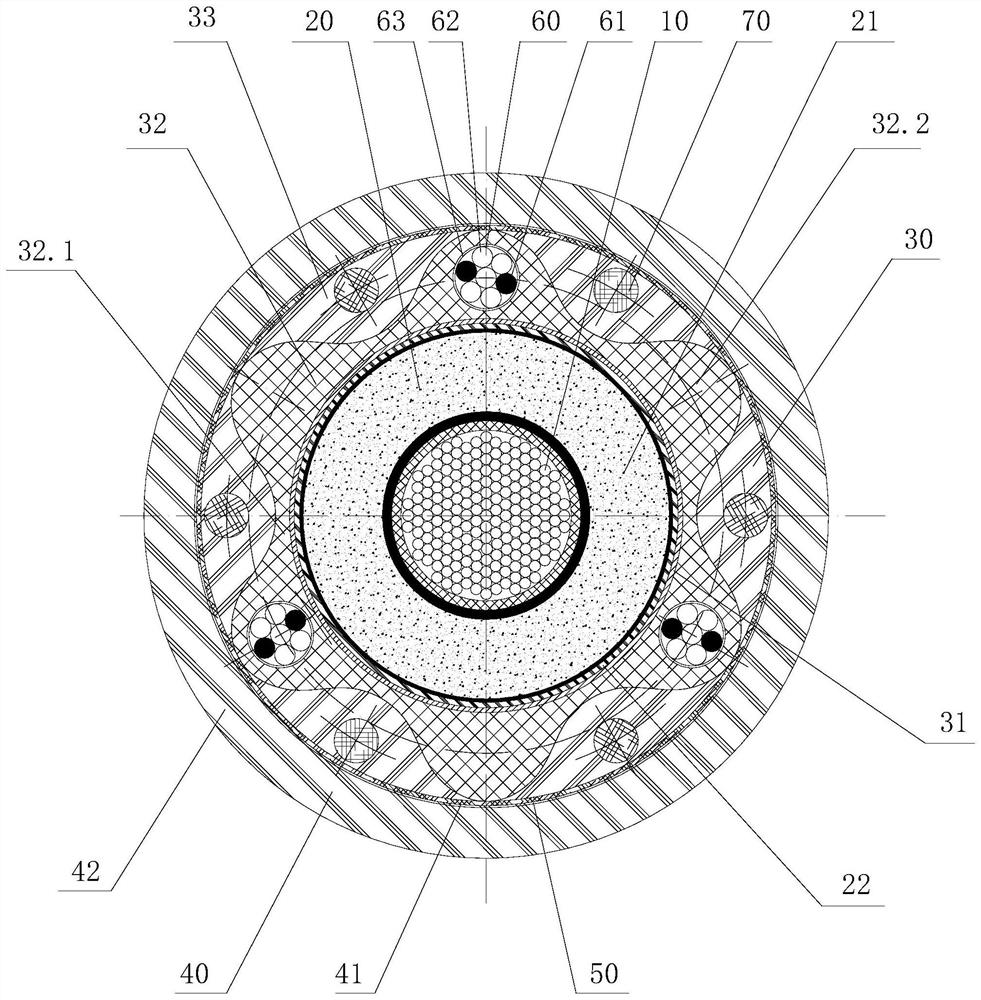

[0062] The composite extruded unit is improved by changing the extension of the fiber unit 60 along the central axis A to helical winding, and the reinforcing fiber bundle 70 is arranged radially outside of the fiber unit 60 . Other structures are with embodiment 1.

[0063] A high-voltage DC optical fiber power composite submarine cable, the conductor core unit 10 and the insulating filler unit 20 constitute a transmission cable core with a circular cross section, and a composite extruded unit 30 is arranged between the cable core and the armored sheath unit, and the glue is exchanged The crest composite part 32.2 of the joint layer 32 and the trough filling part 33.1 of the rubberized elastic layer 33 are alternately arranged around the transmission cable core along the central axis A with a certain pitch h, and the pitch h satisfies 100mm≤h≤500mm. The rubberized elastic layer 33 includes a trough filling part 33.1 filling the space between the crest compounding parts 32.2 a...

Embodiment 3

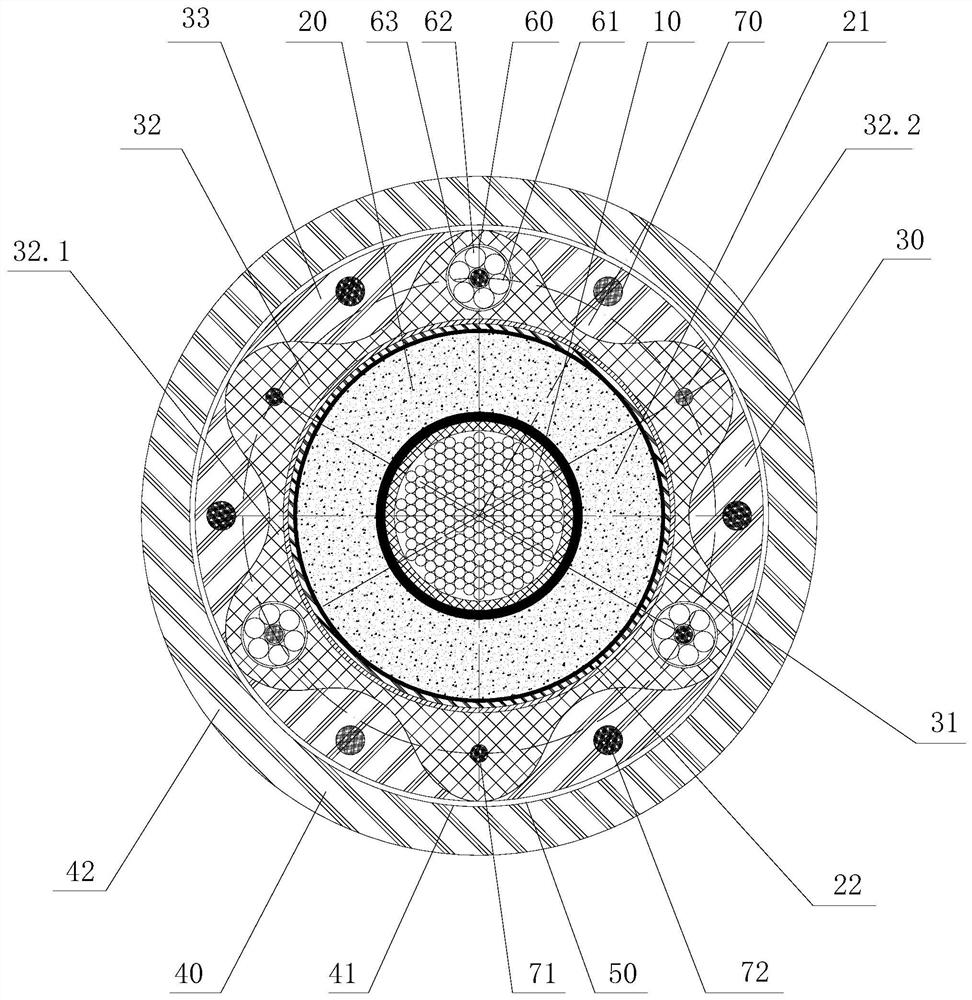

[0067] The composite extrusion unit is improved, and a structure that strengthens interface bonding is added, and other structures are the same as those in Embodiment 1 or 2.

[0068] A high-voltage DC optical fiber power composite submarine cable, the conductor core unit 10 and the insulating filler unit 20 constitute a transmission cable core with a circular cross-section, and a composite extrusion unit 30 is arranged between the cable core and the armored sheath unit, and also includes a device Joint strengthening unit at interface joints of different properties. The joint strengthening unit includes a water-blocking adhesive layer 50 and a bonding reinforcement structure 90, and the water-blocking adhesive layer 50 is arranged between the insulating filler unit 20 and the composite extrusion unit 30, or the armored sheath unit 40 and the composite extruded unit 30, or between the braided armor layer 41 and the adjacent sheath layer 42 and the rubberized elastic layer 33, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com