Patents

Literature

43results about How to "Increase the tensile load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

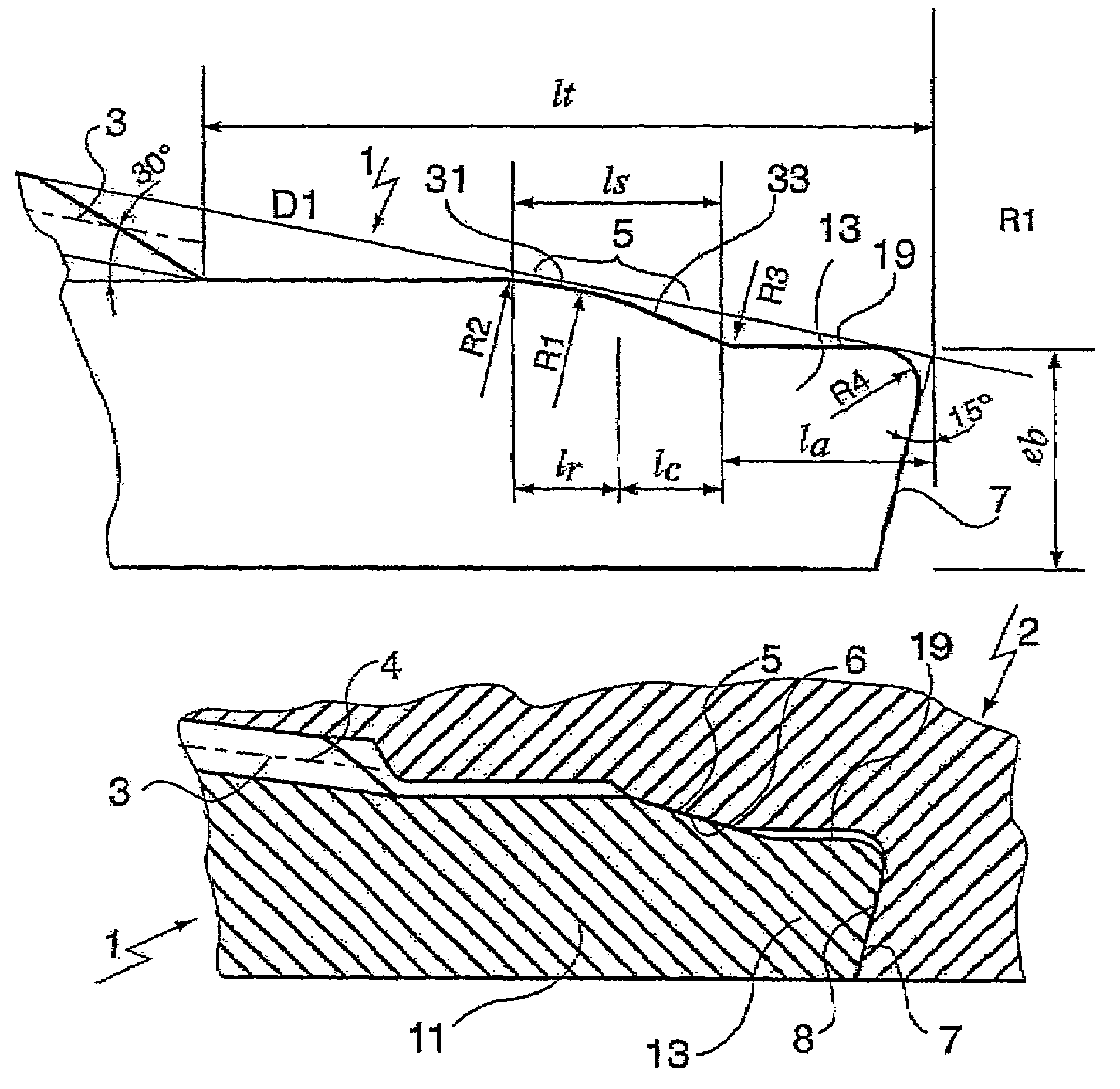

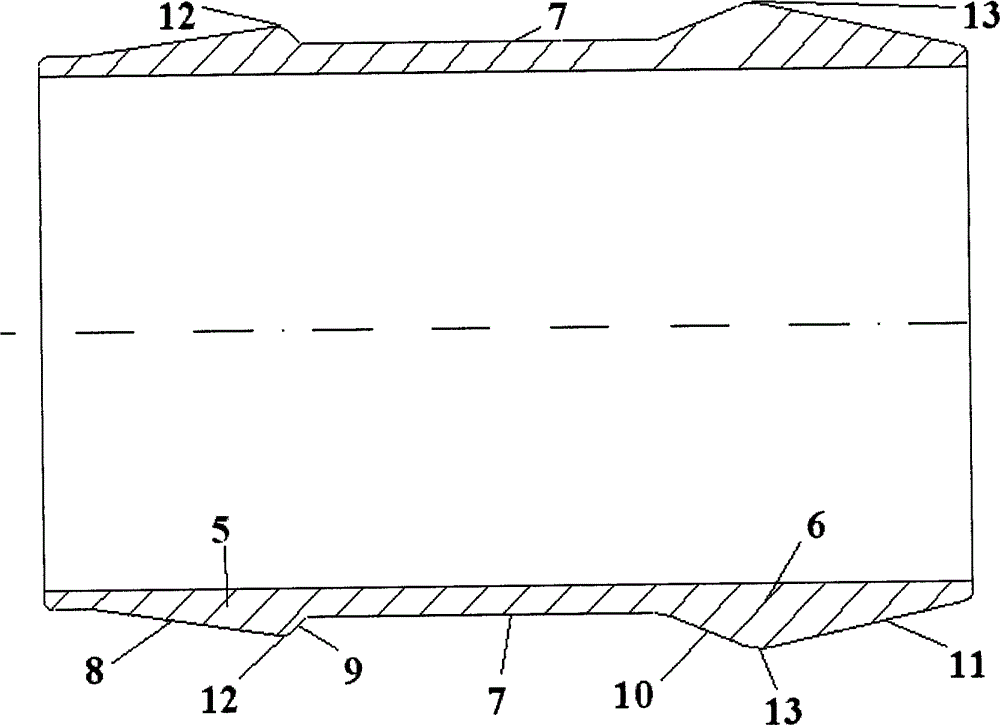

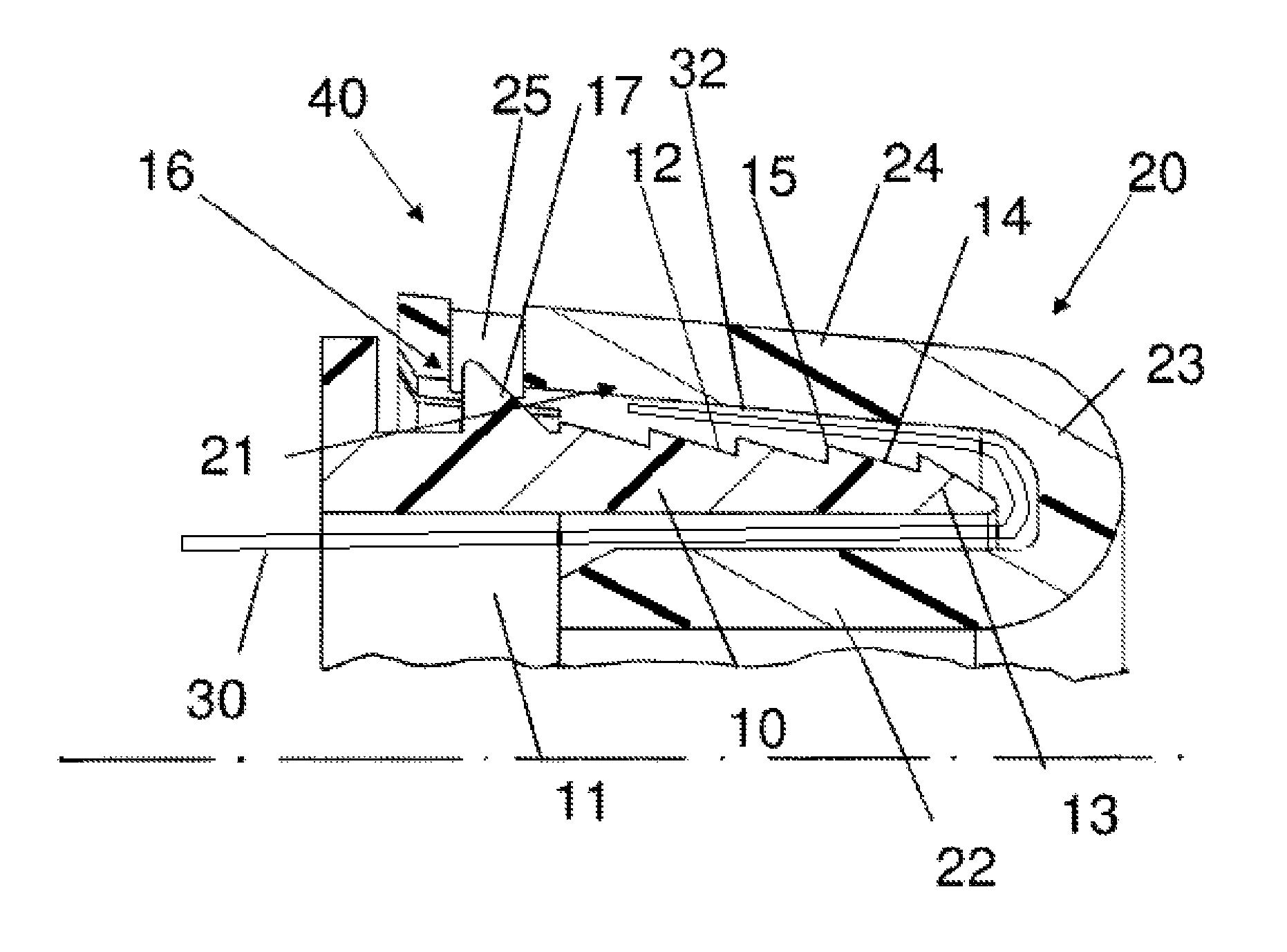

Premium threaded tubular joint comprising at least a threaded element with end lip

InactiveUS7334821B2Reduce axial stiffnessImprove elastic deformation abilityDrilling rodsFluid pressure sealed jointsThreaded pipeAxial compression

A premium threaded tubular connection including, on at least one threaded element, a distal abutment surface at the free end of a threaded element, and a lip sealing surface at a given distance from the threading. The lip includes an appendix that extends the lip towards its free end beyond the lip sealing surface so that the lip has both high radial stiffness and low axial stiffness. This results in enhanced performance as regards the seal of the threaded connection under pressure and / or under tension, and other advantages of precision of real makeup torque, mechanical strength in axial compression, a shock barrier effect, and tolerance in engaging the threaded elements.

Owner:NIPPON STEEL CORP

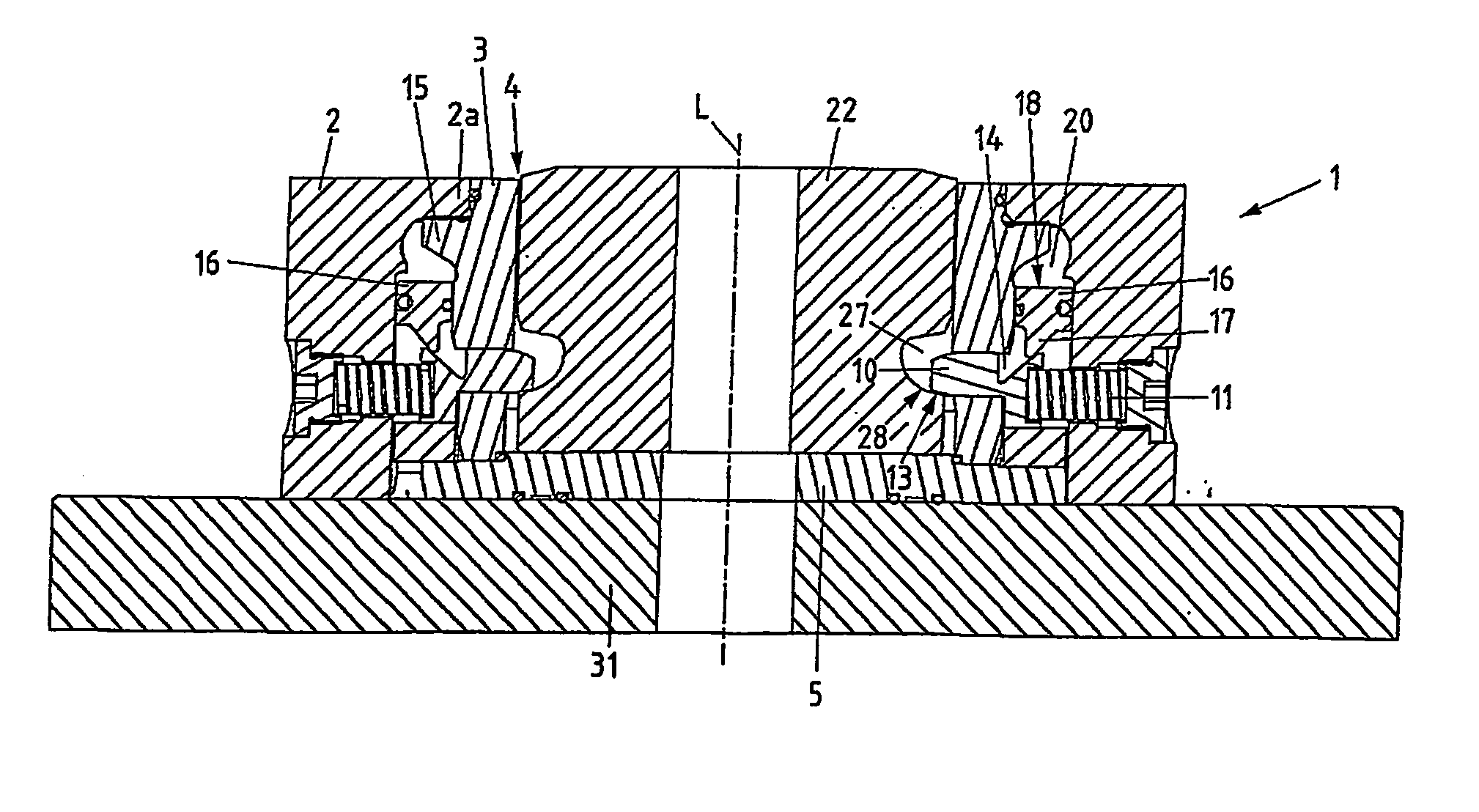

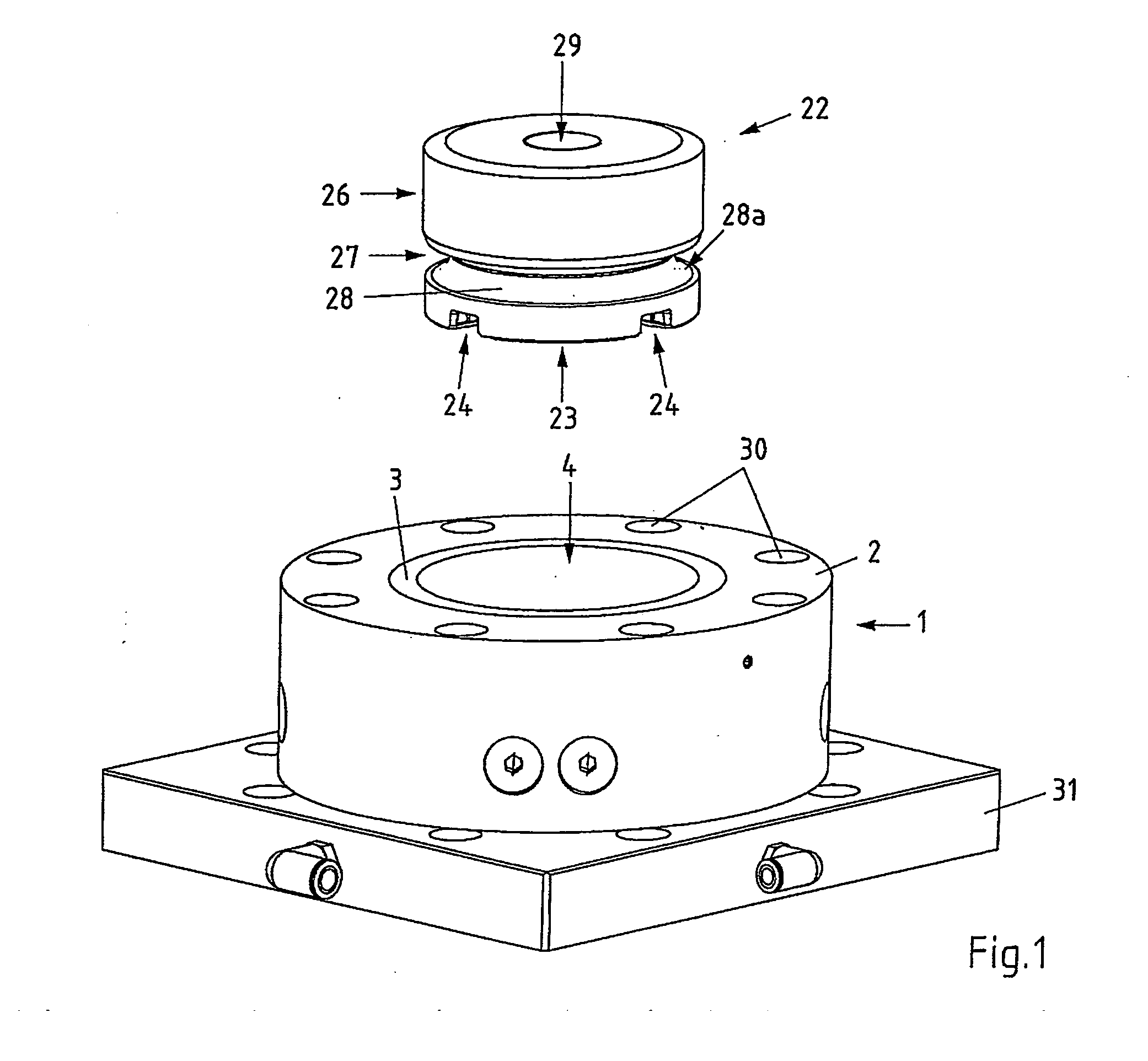

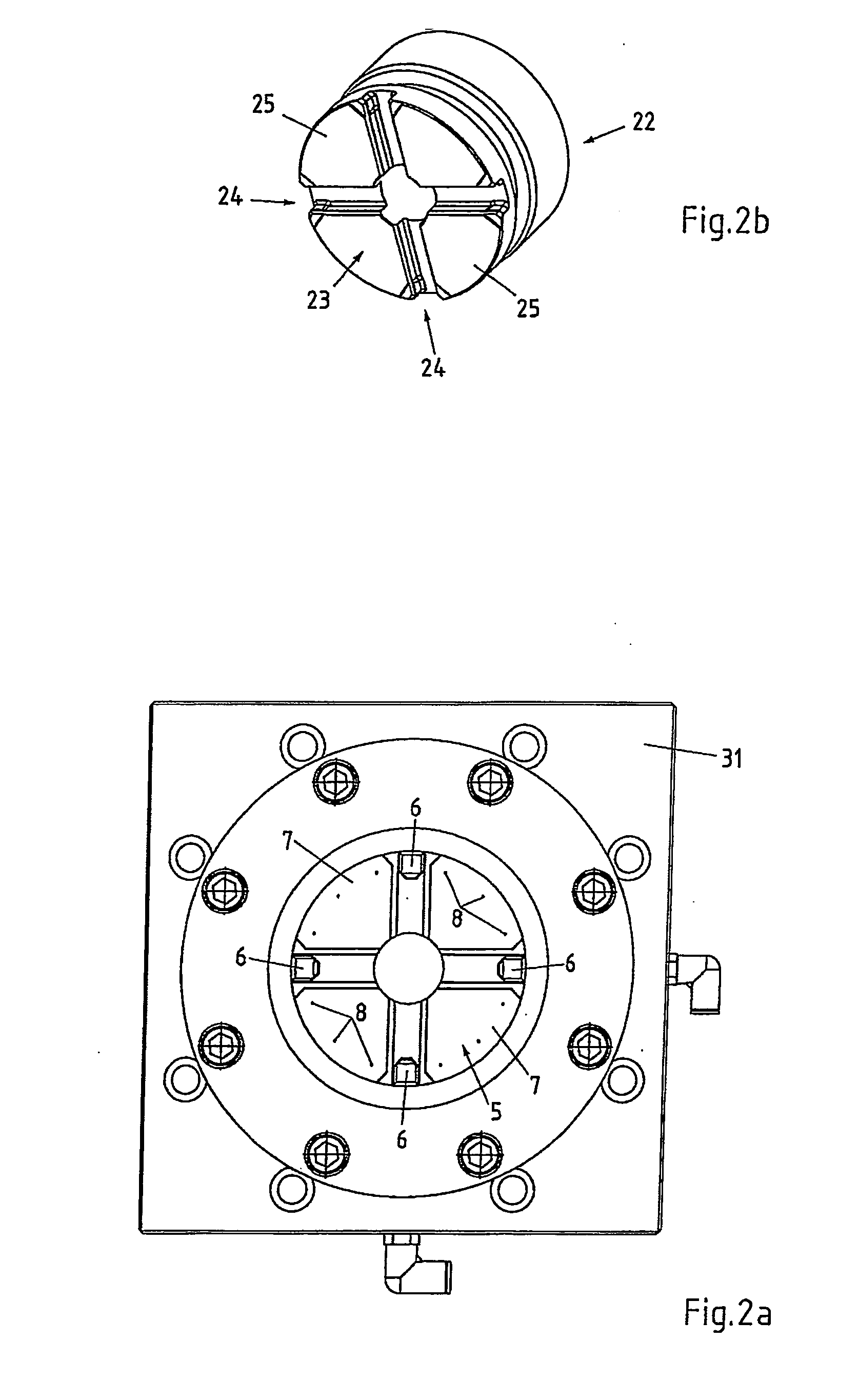

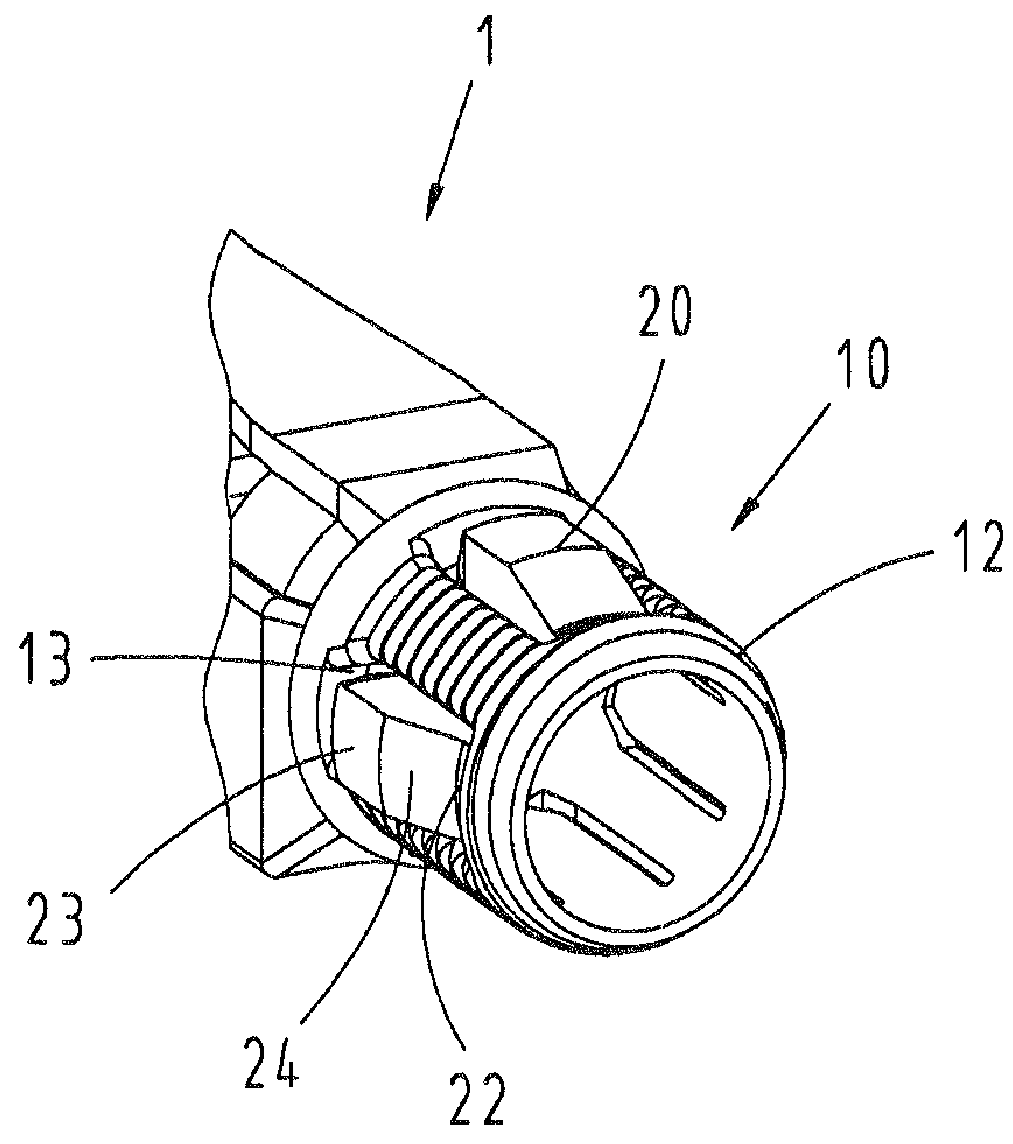

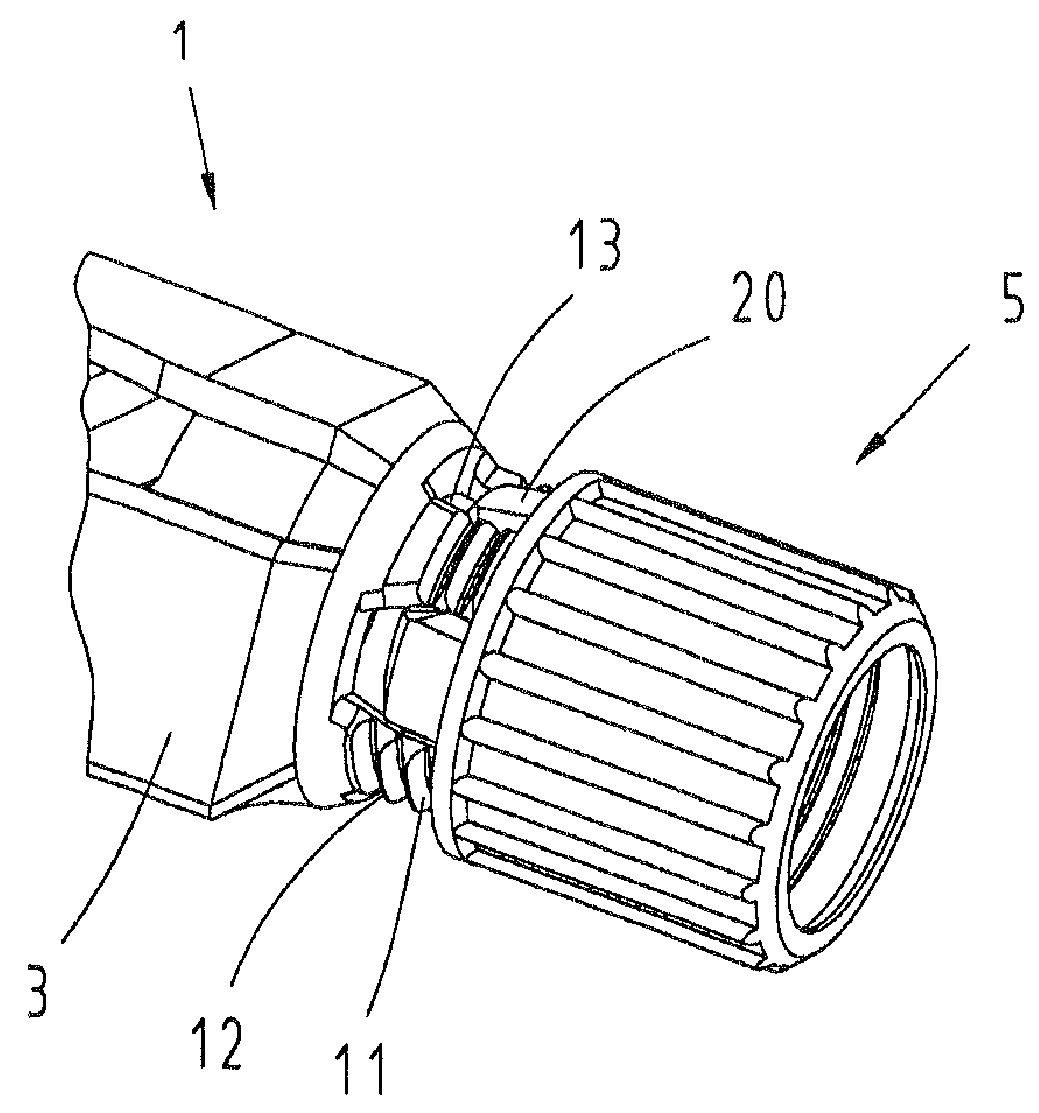

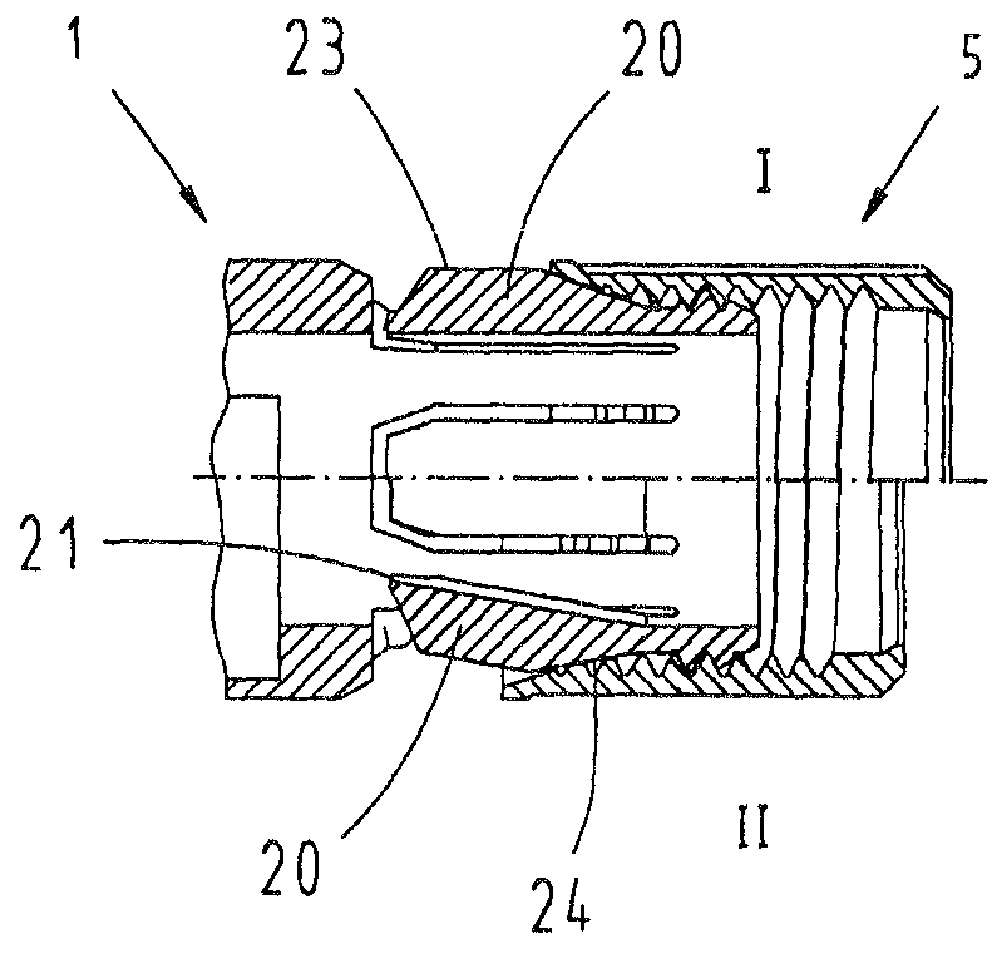

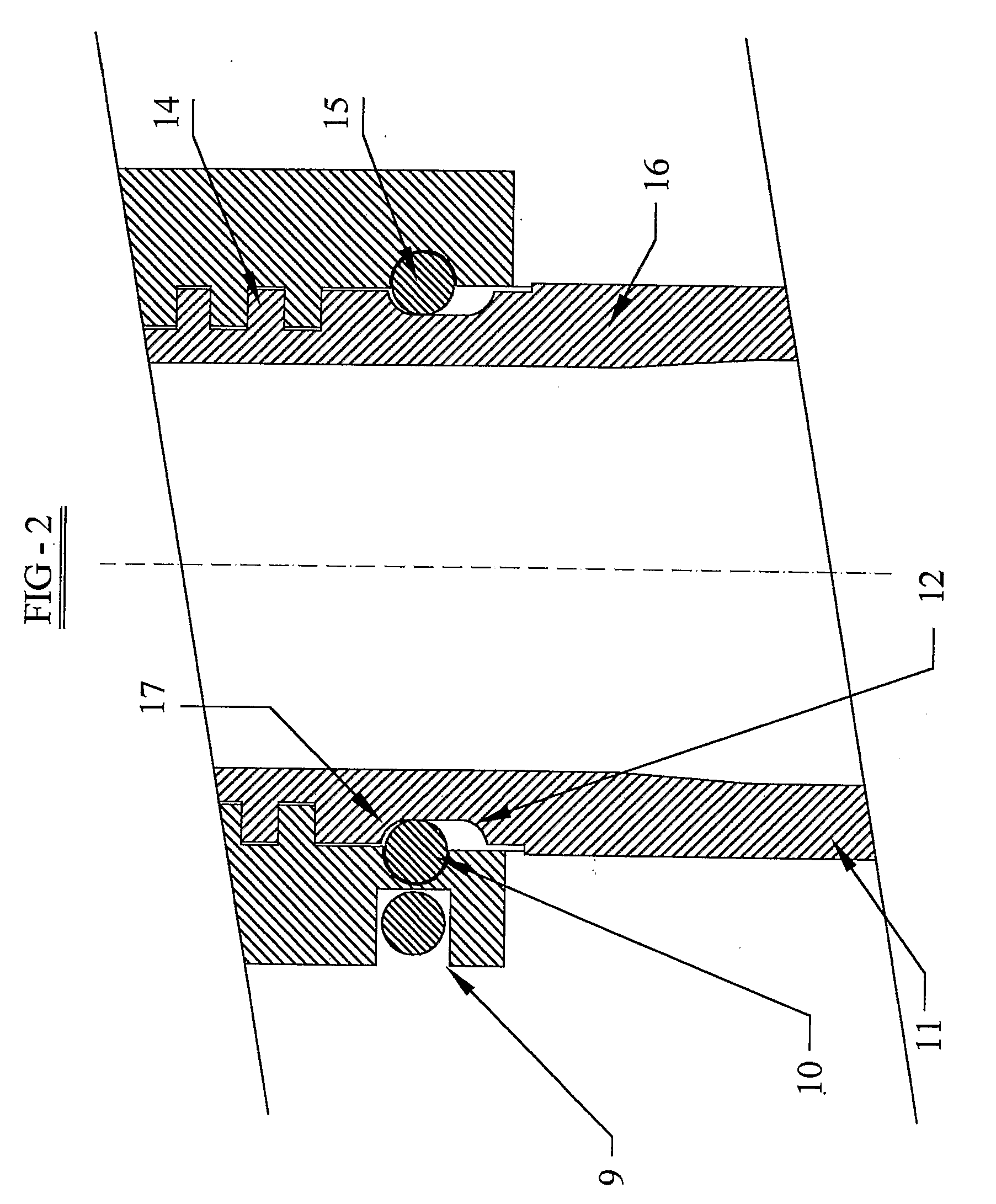

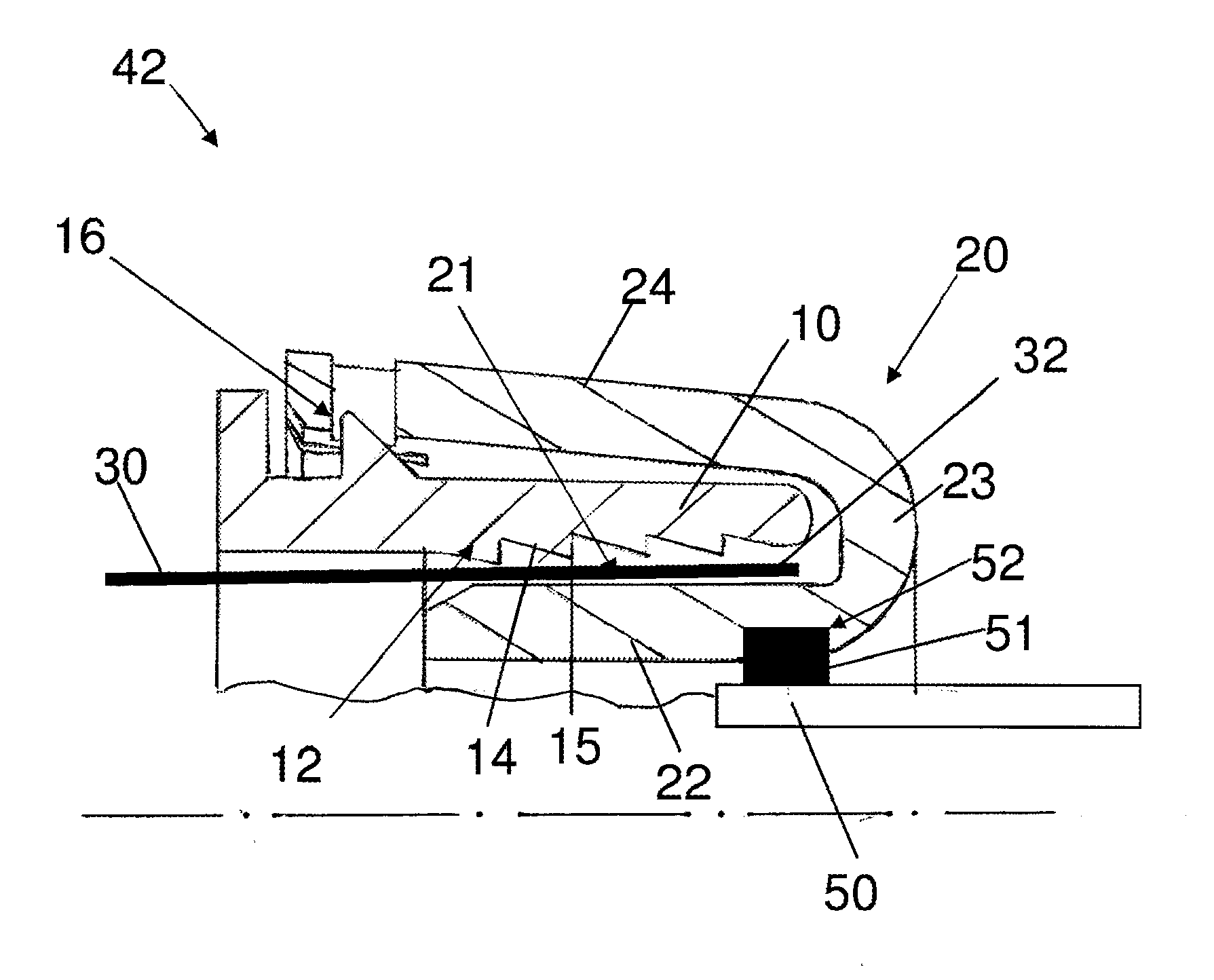

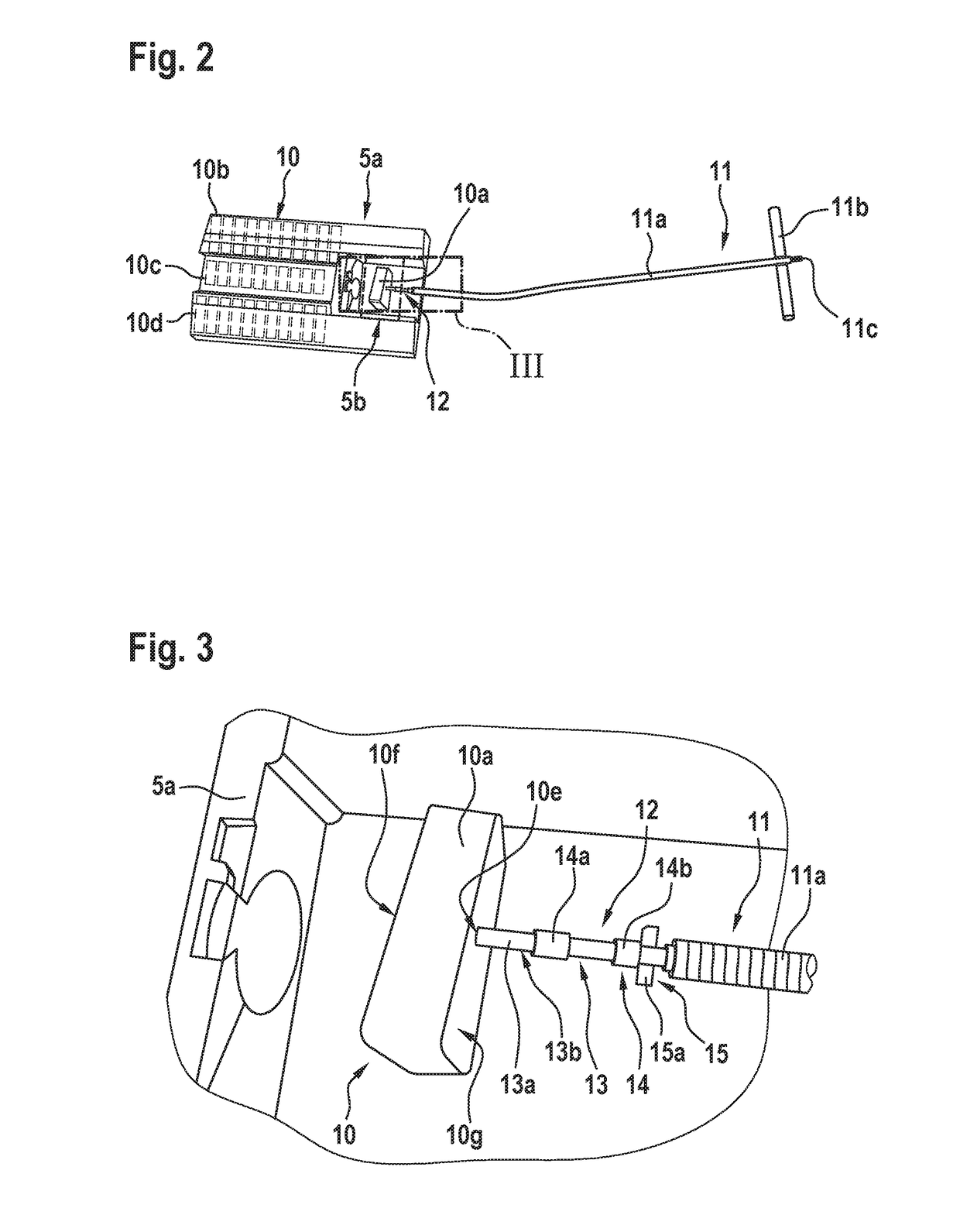

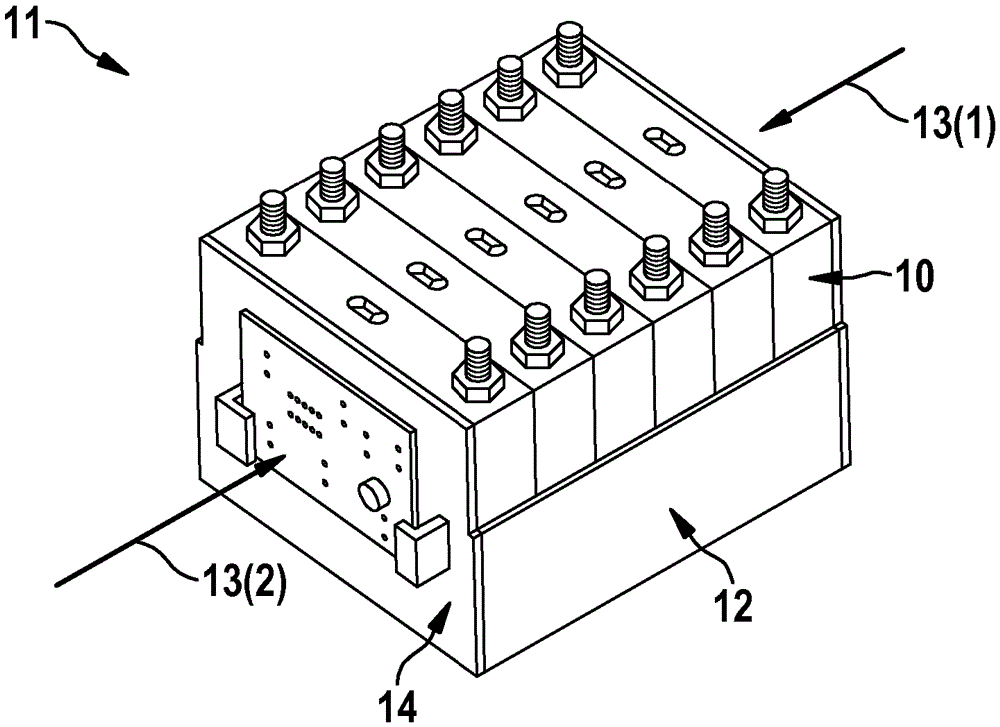

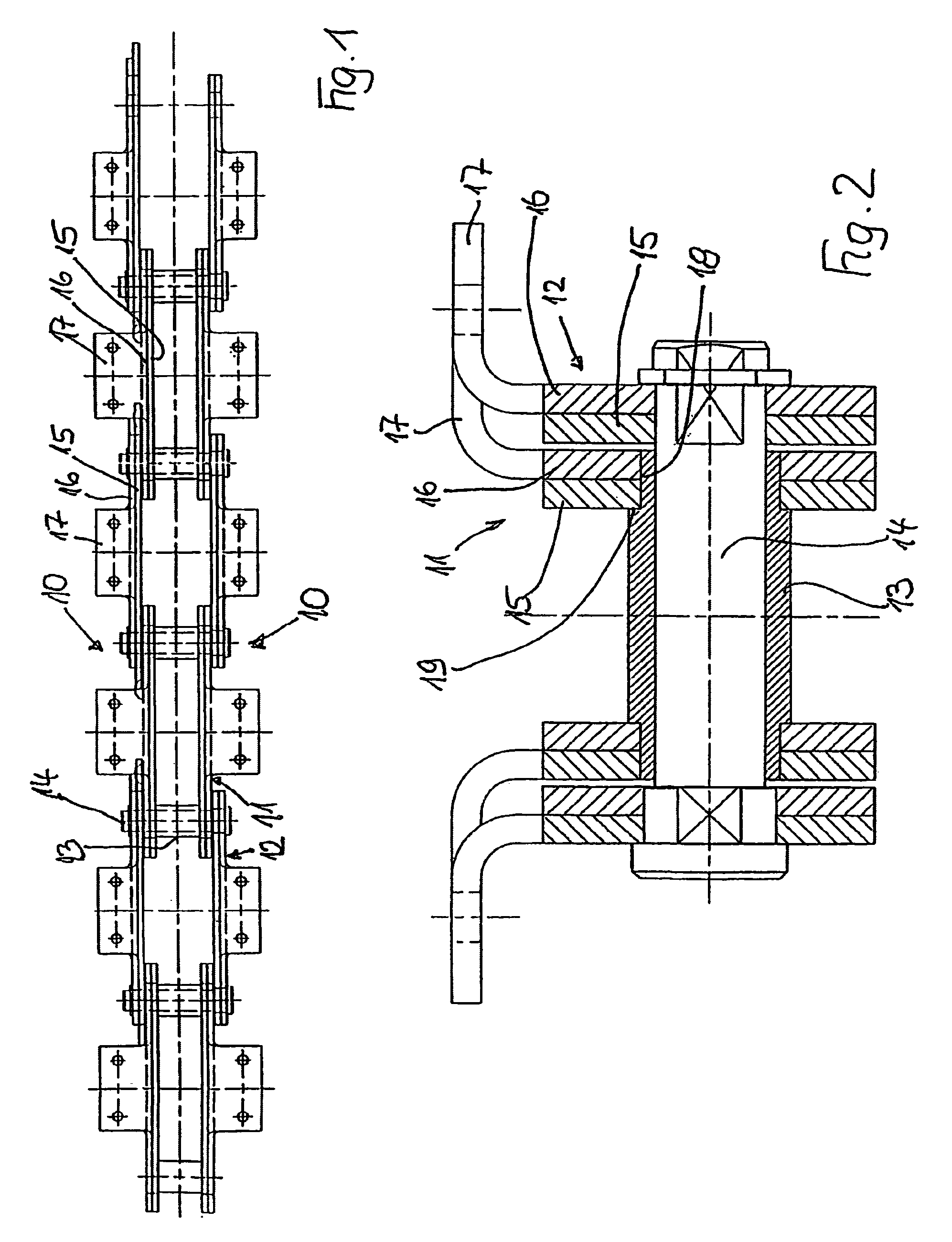

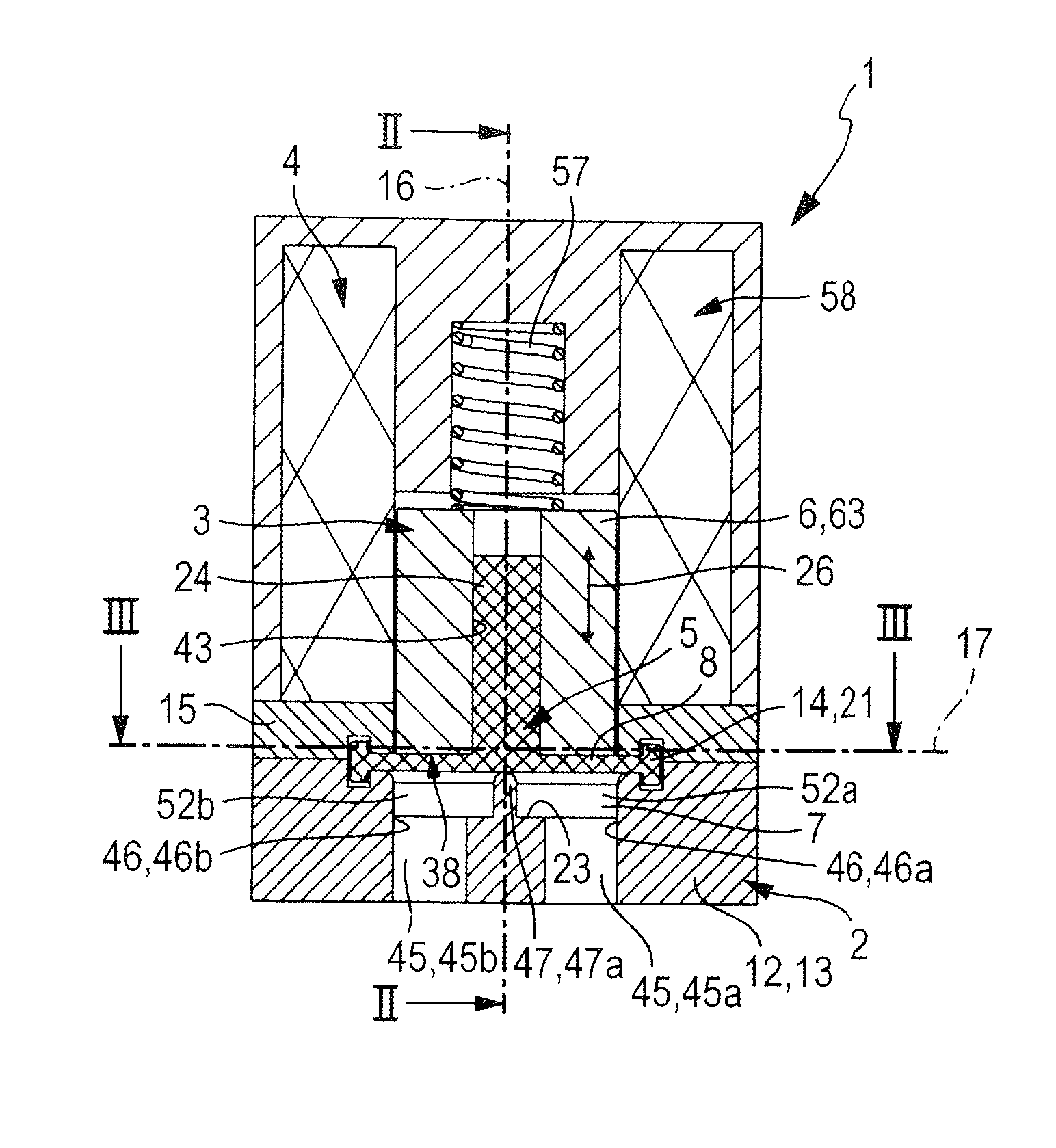

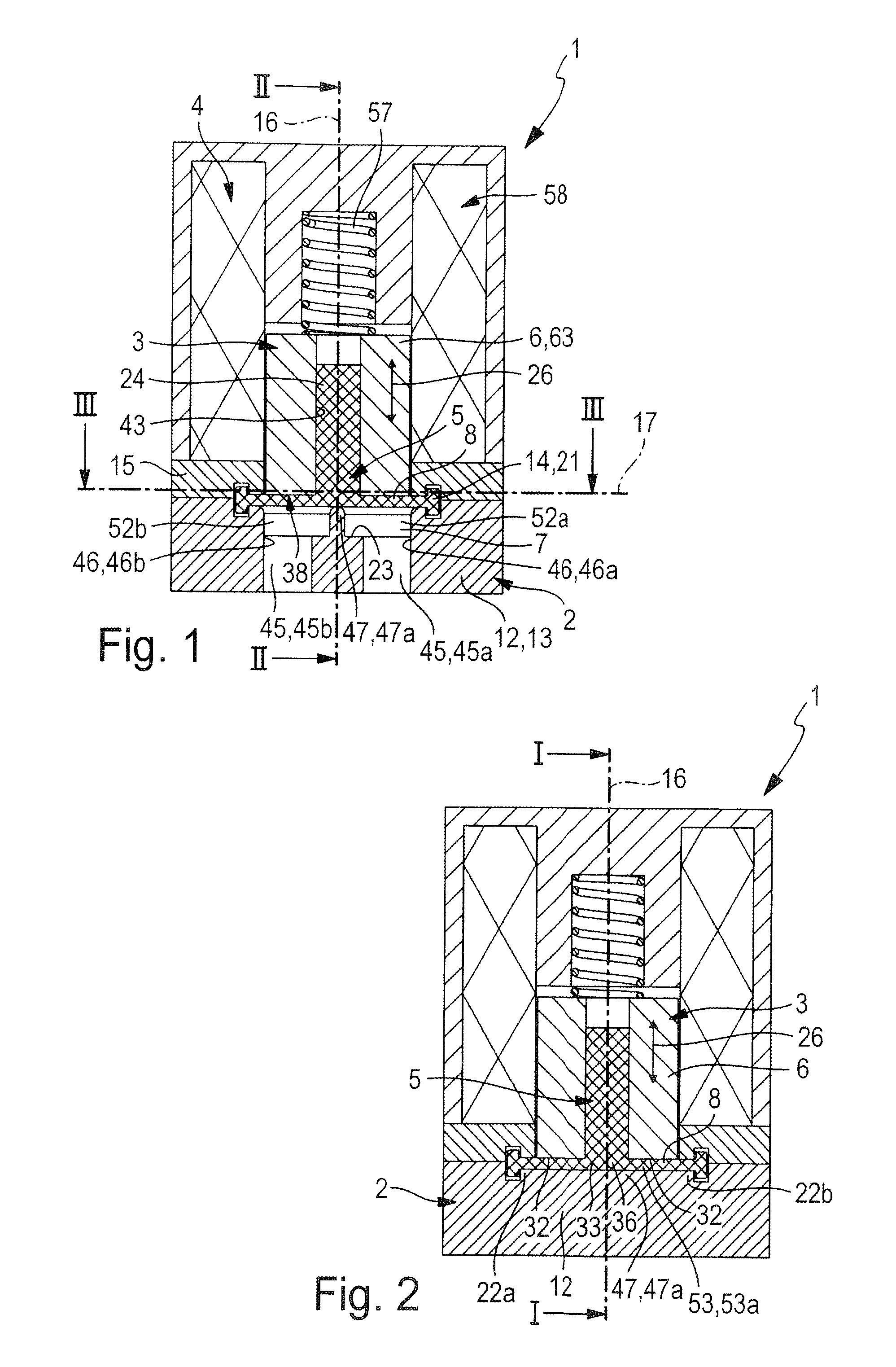

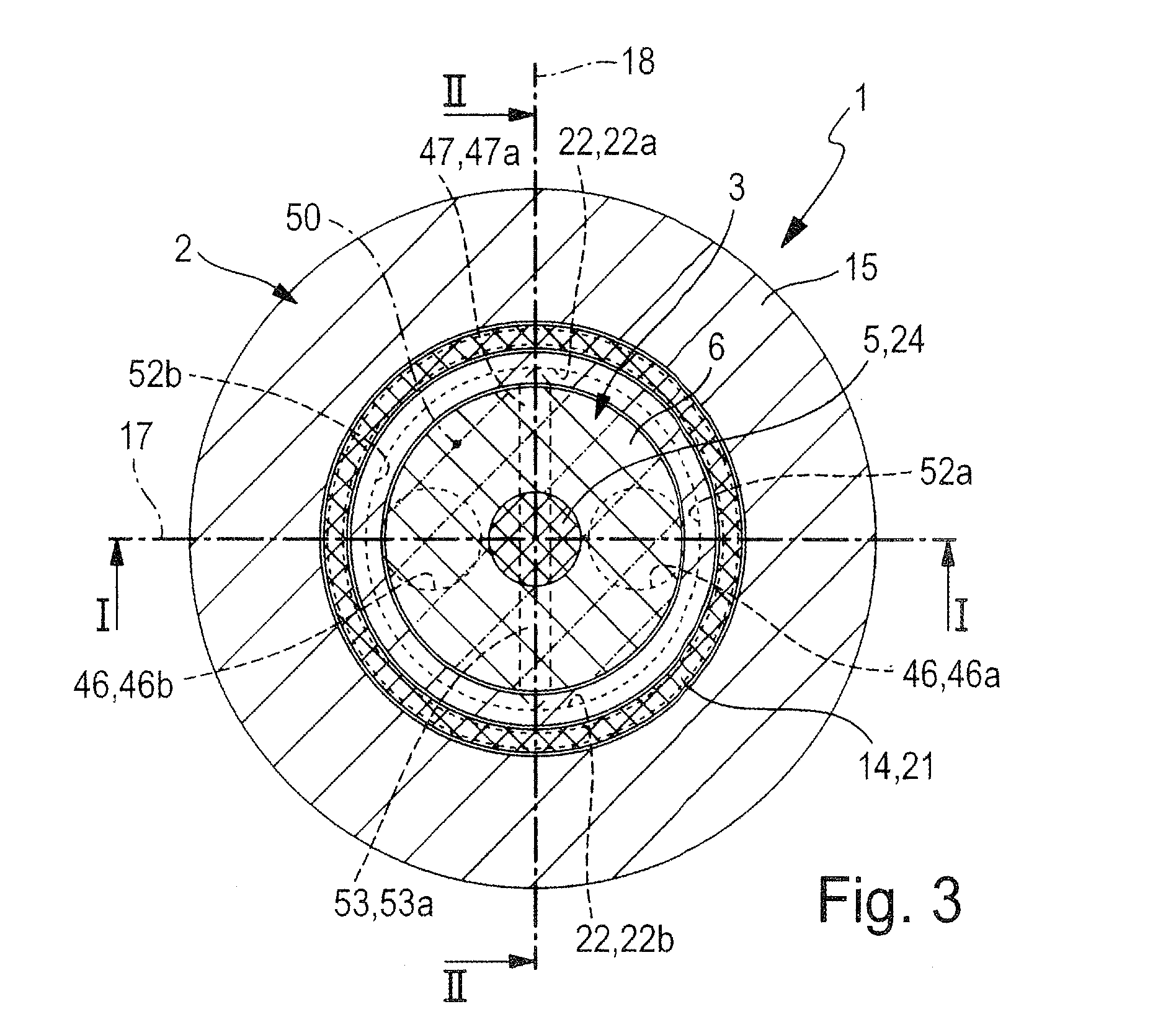

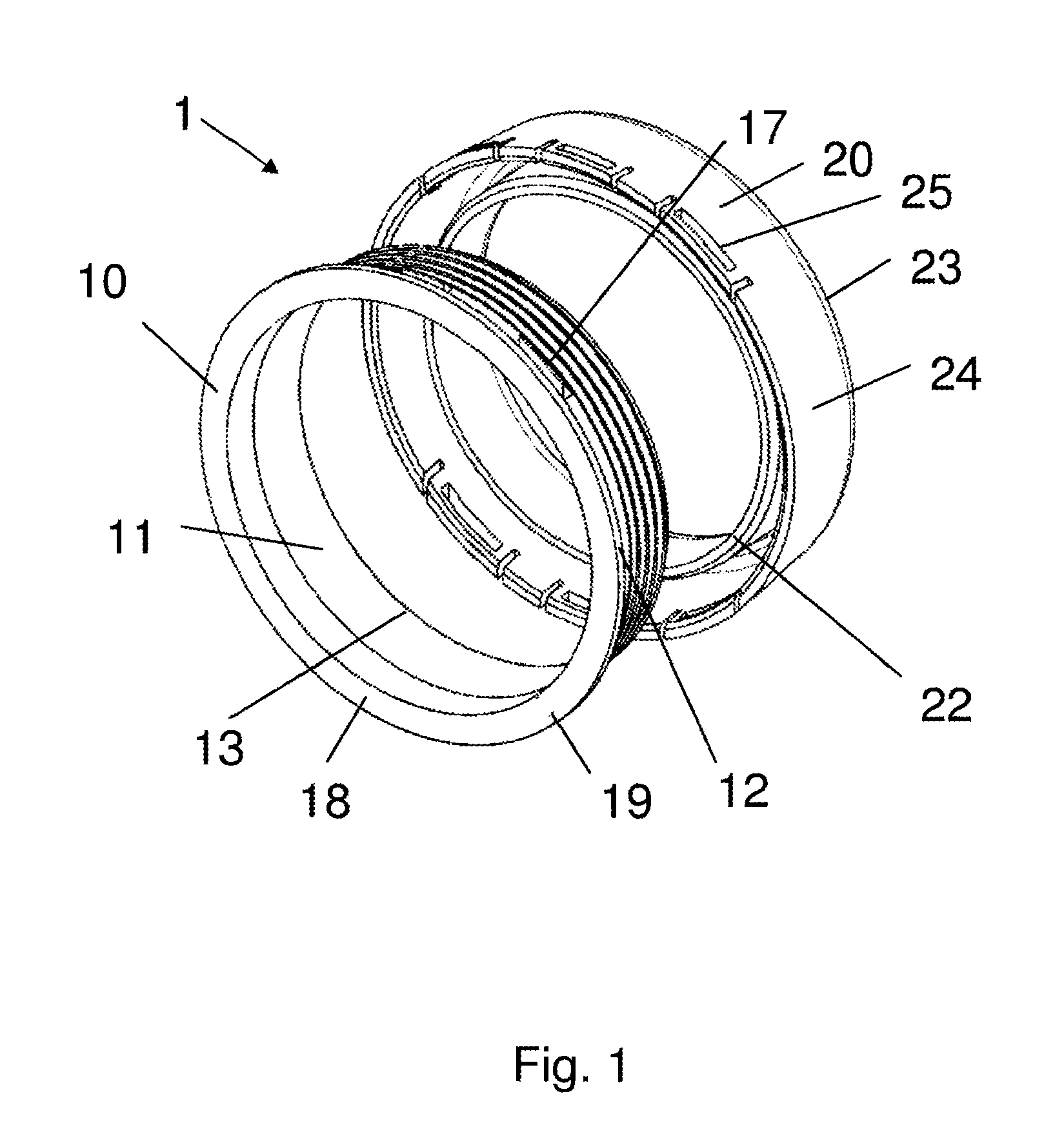

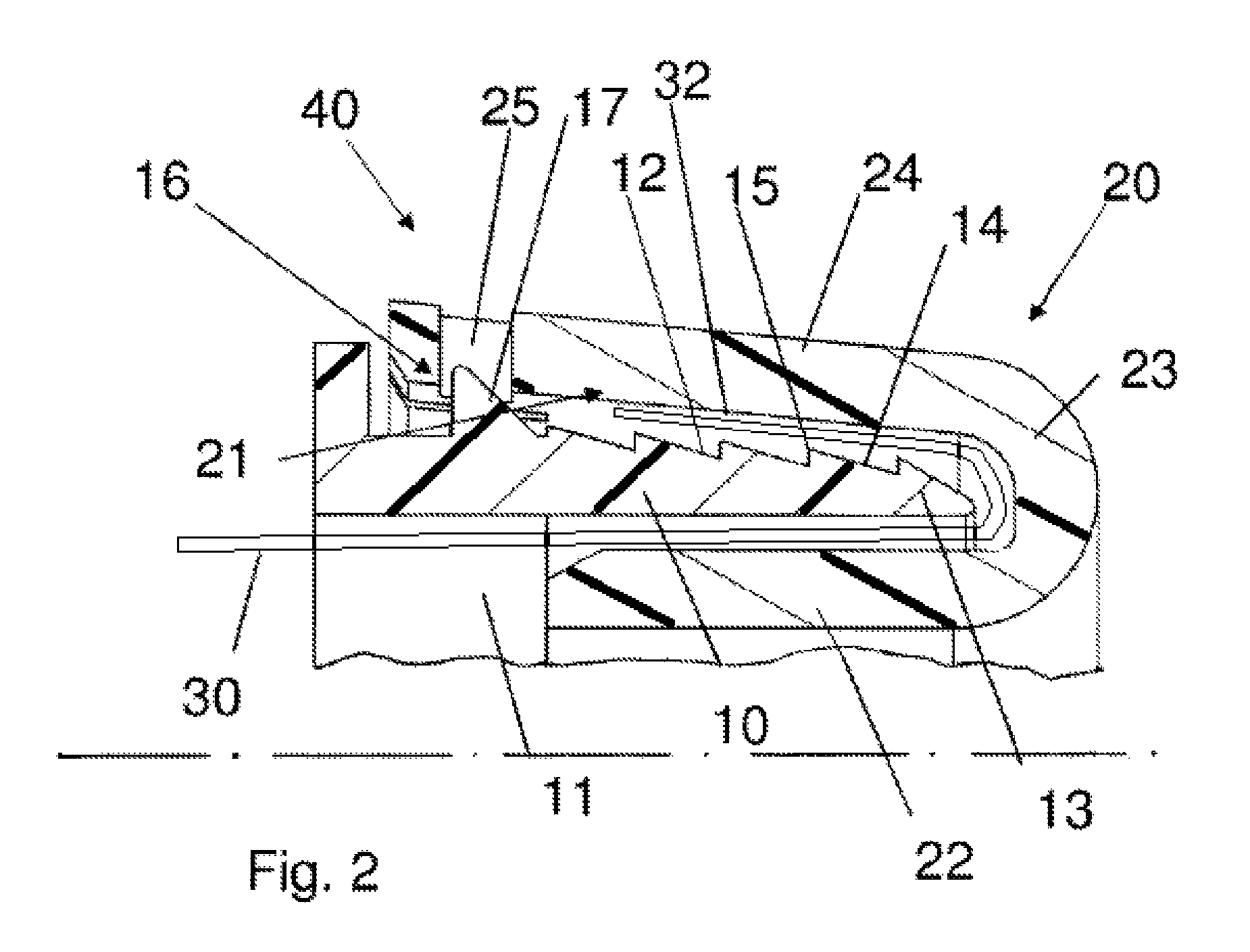

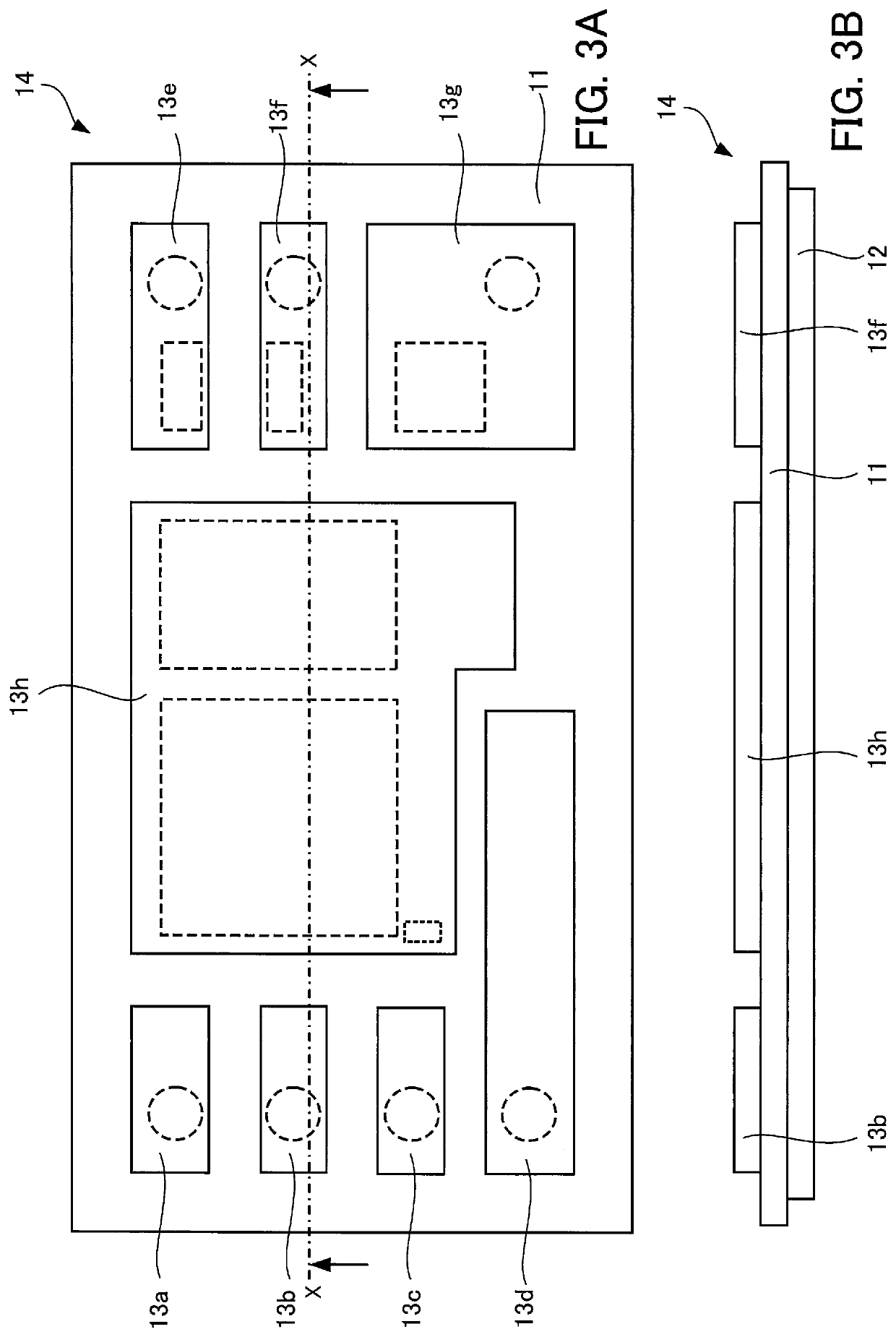

Clamping fixture including a chuck and a workpiece pallet releasably located thereon

ActiveUS20090051094A1Increase the tensile loadHandle high tensile loadRotary cutting toolsLarge fixed membersEngineeringPlunger

A clamping fixture comprises a chuck (1) and a workpiece pallet (22) releasably located thereon. The chuck (1) is provided with a clamping mechanism for locating the workpiece pallet (22). The clamping mechanism comprises a plurality of clamping members configured as plungers (10). The workpiece pallet (22) comprises a clamping surface (28a) running essentially along its shell surface (26) for surface contacting the plungers (10) by its front part (12) provided with a compression surface (13) during clamping.

Owner:EROWA

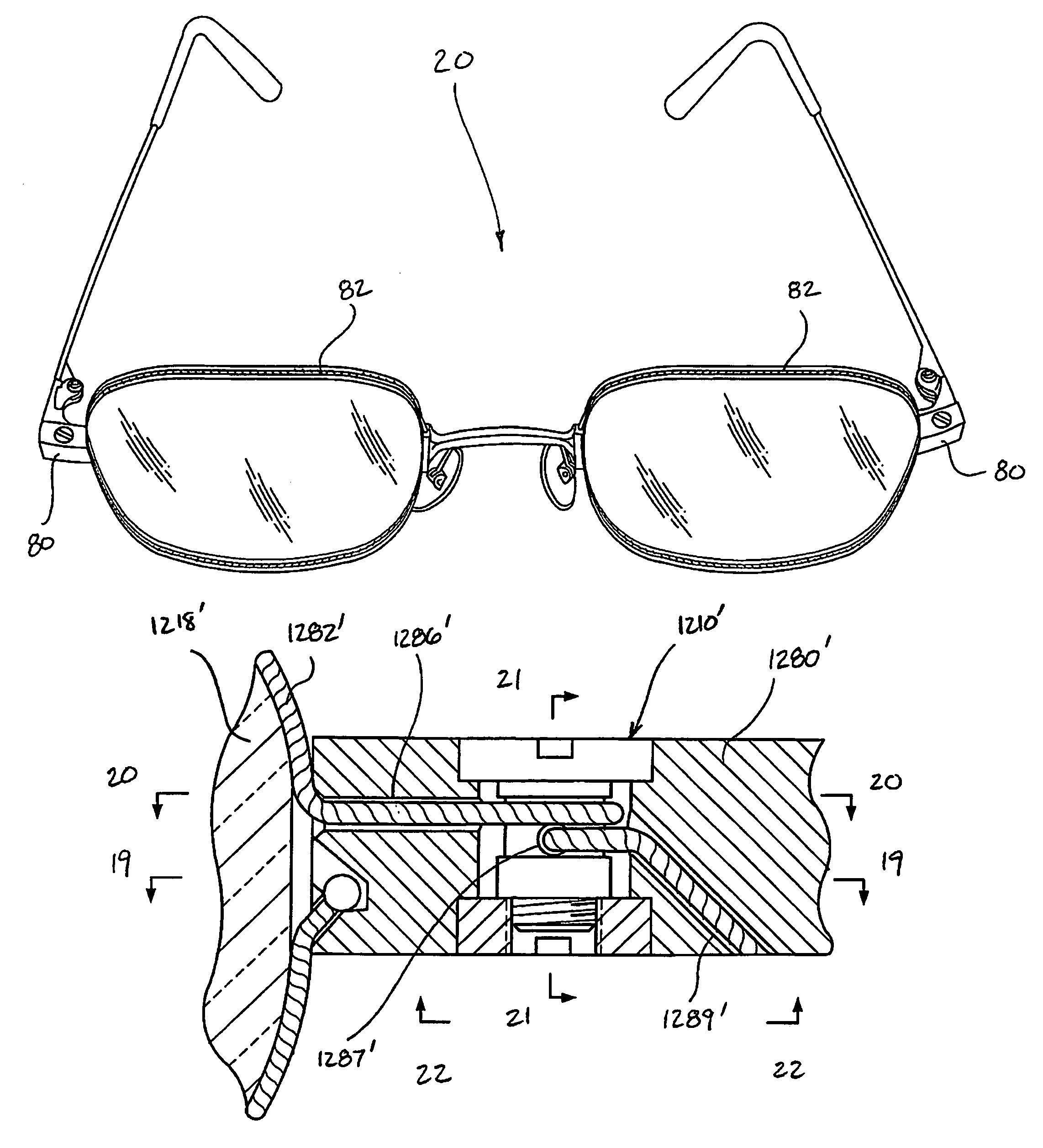

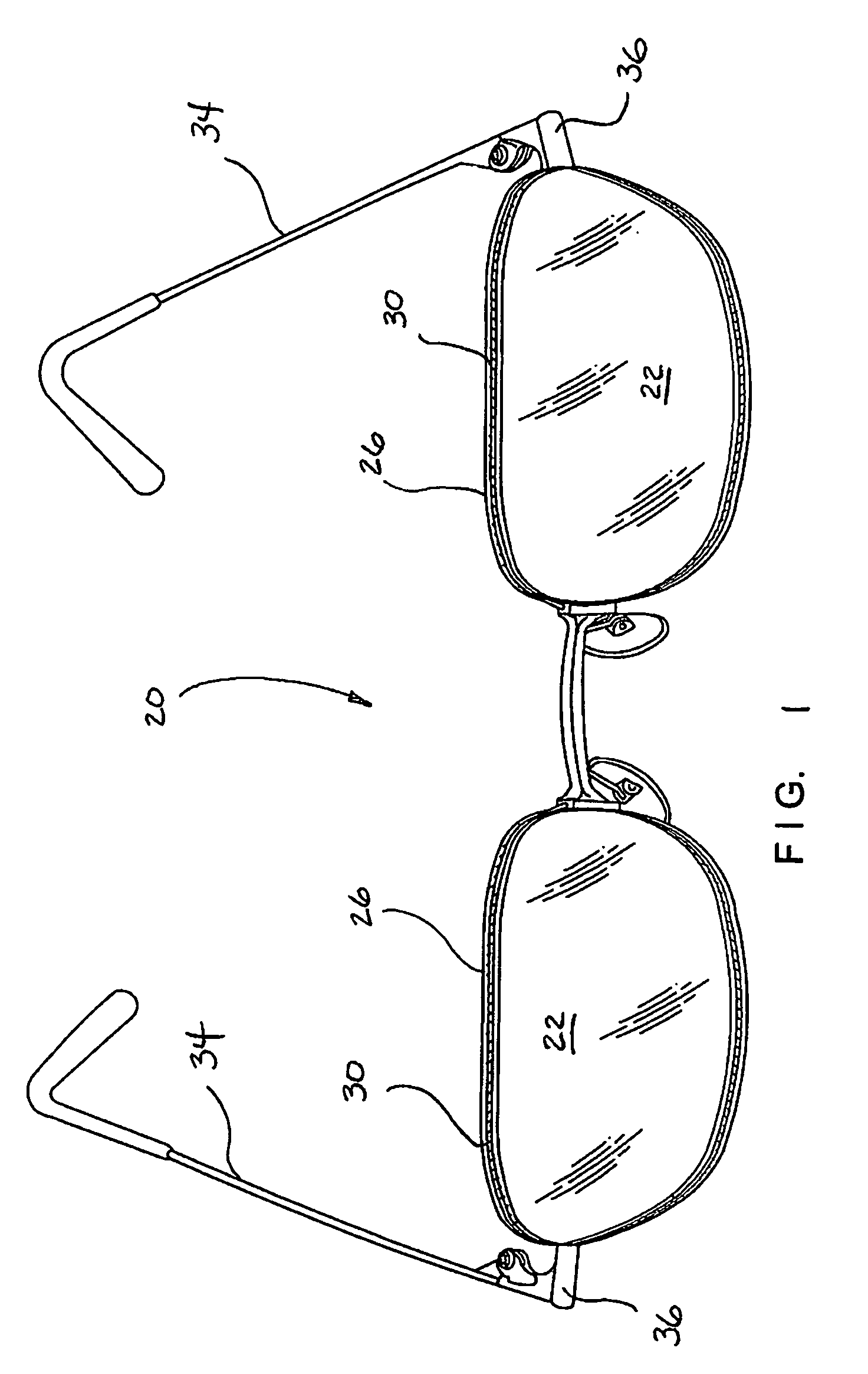

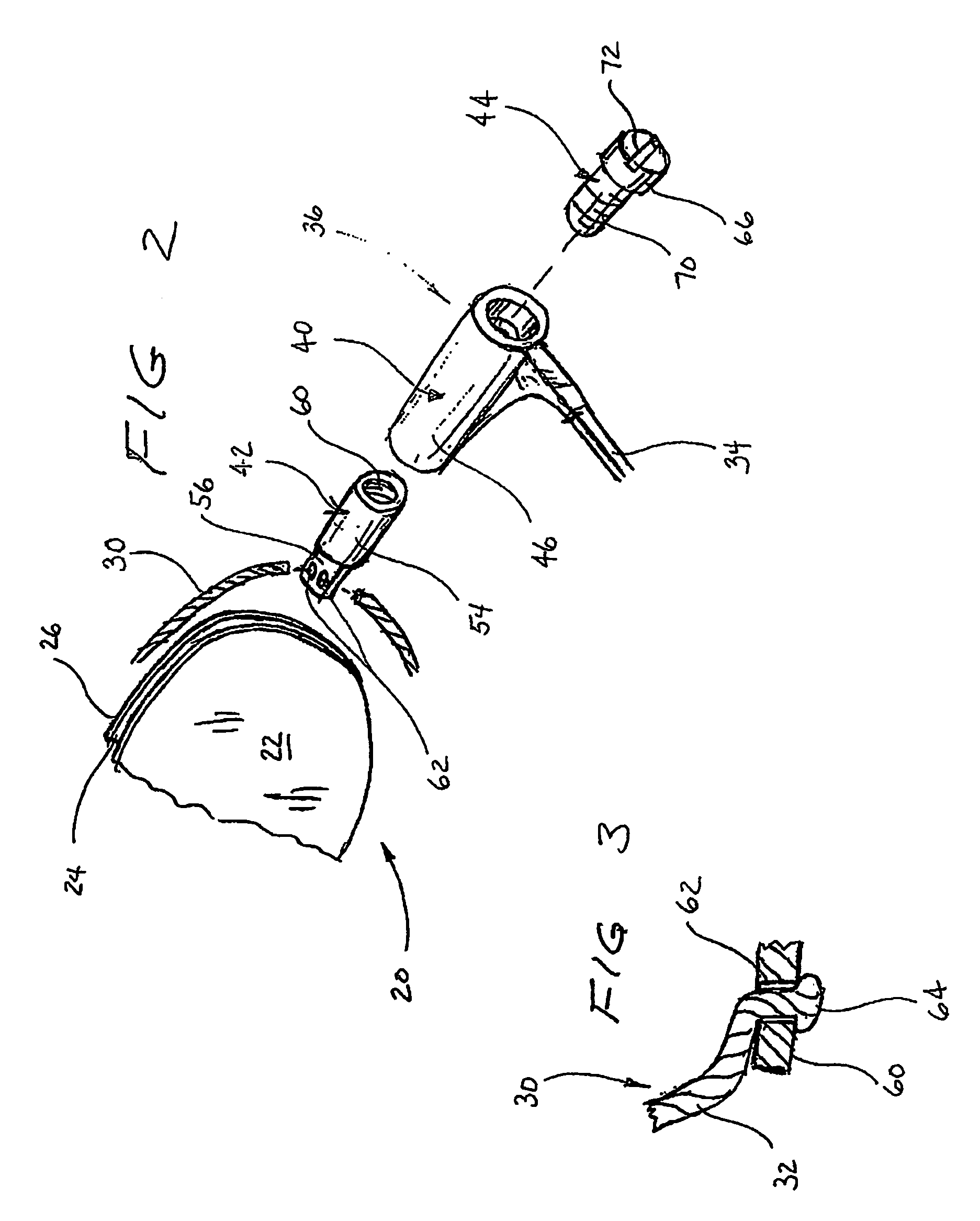

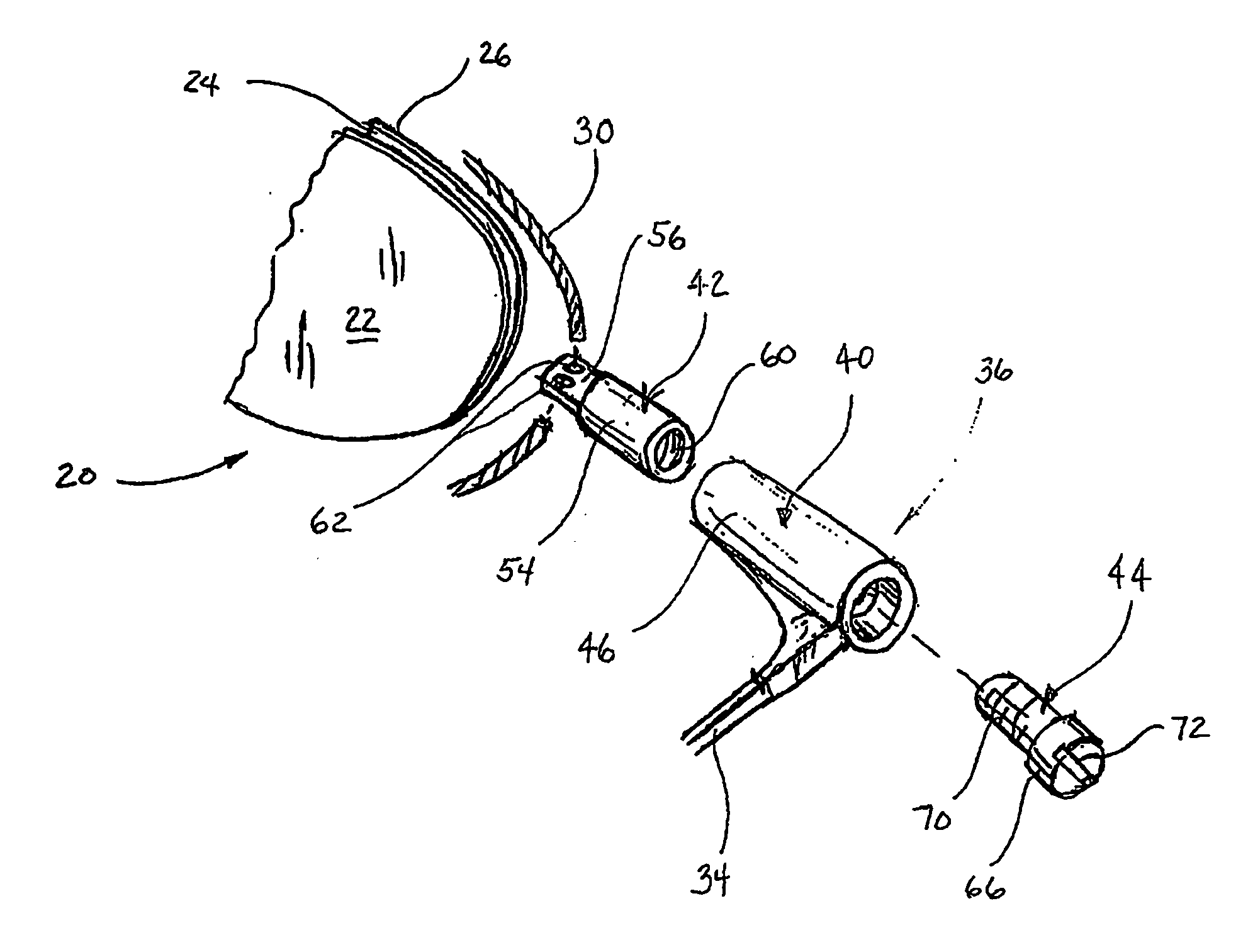

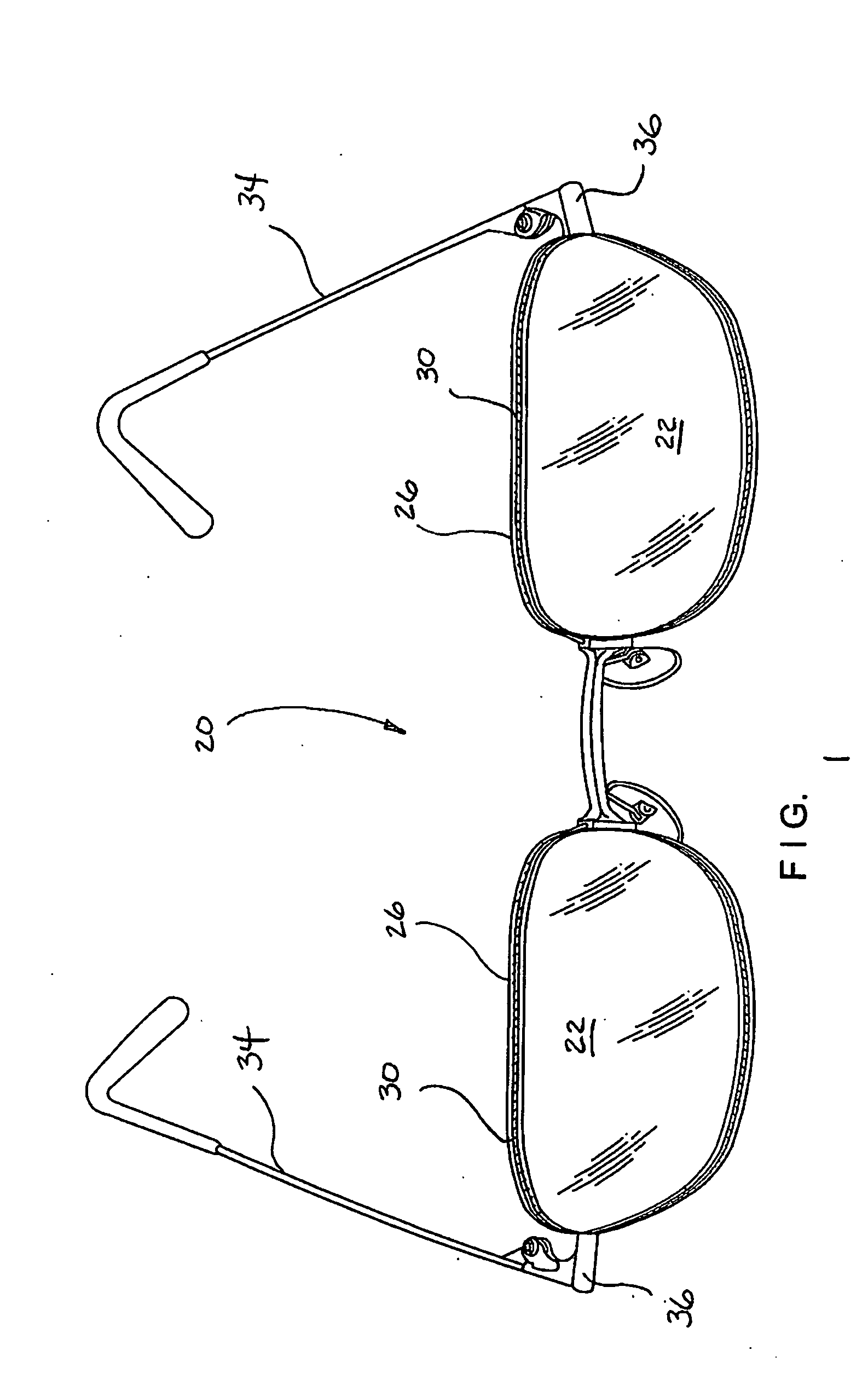

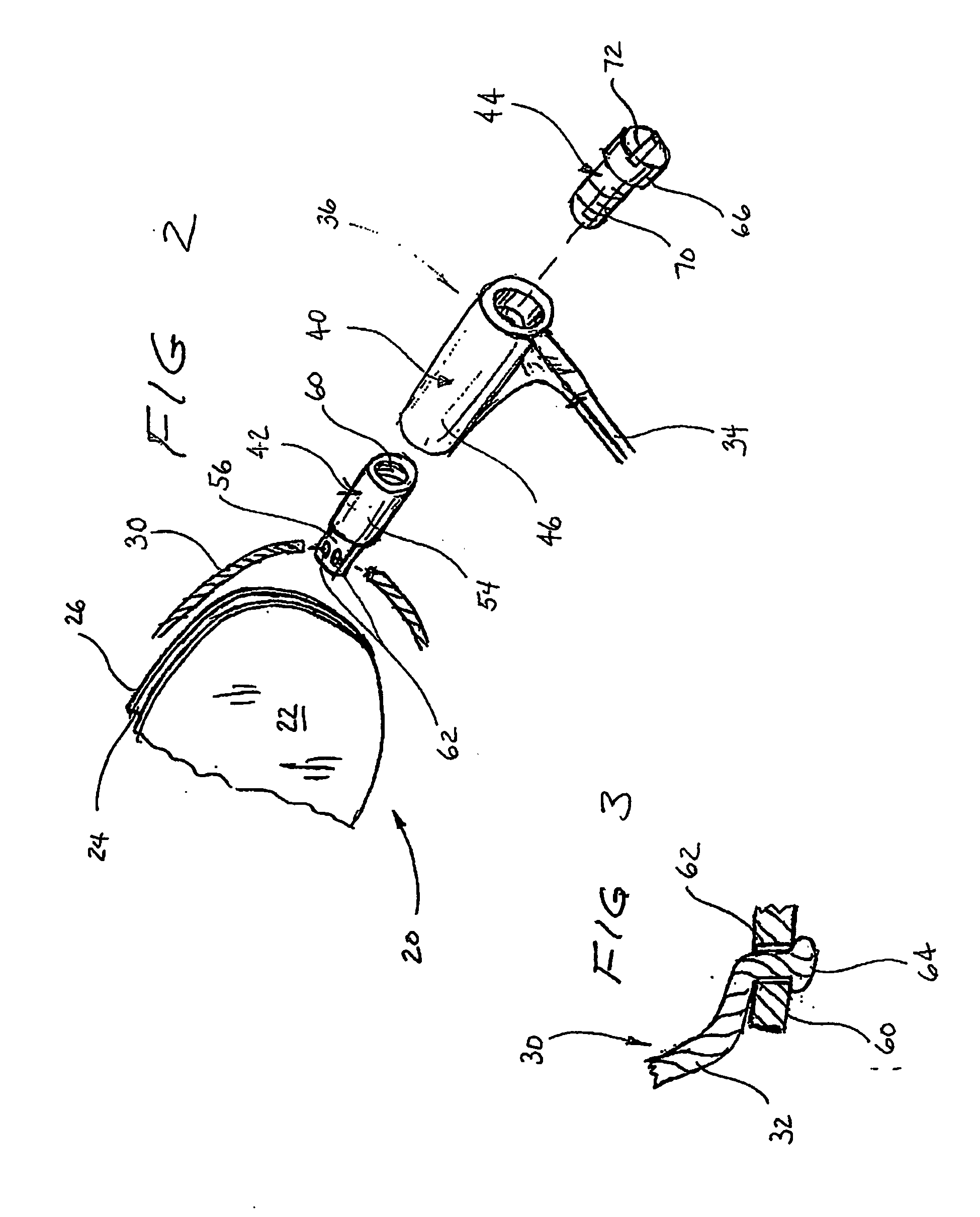

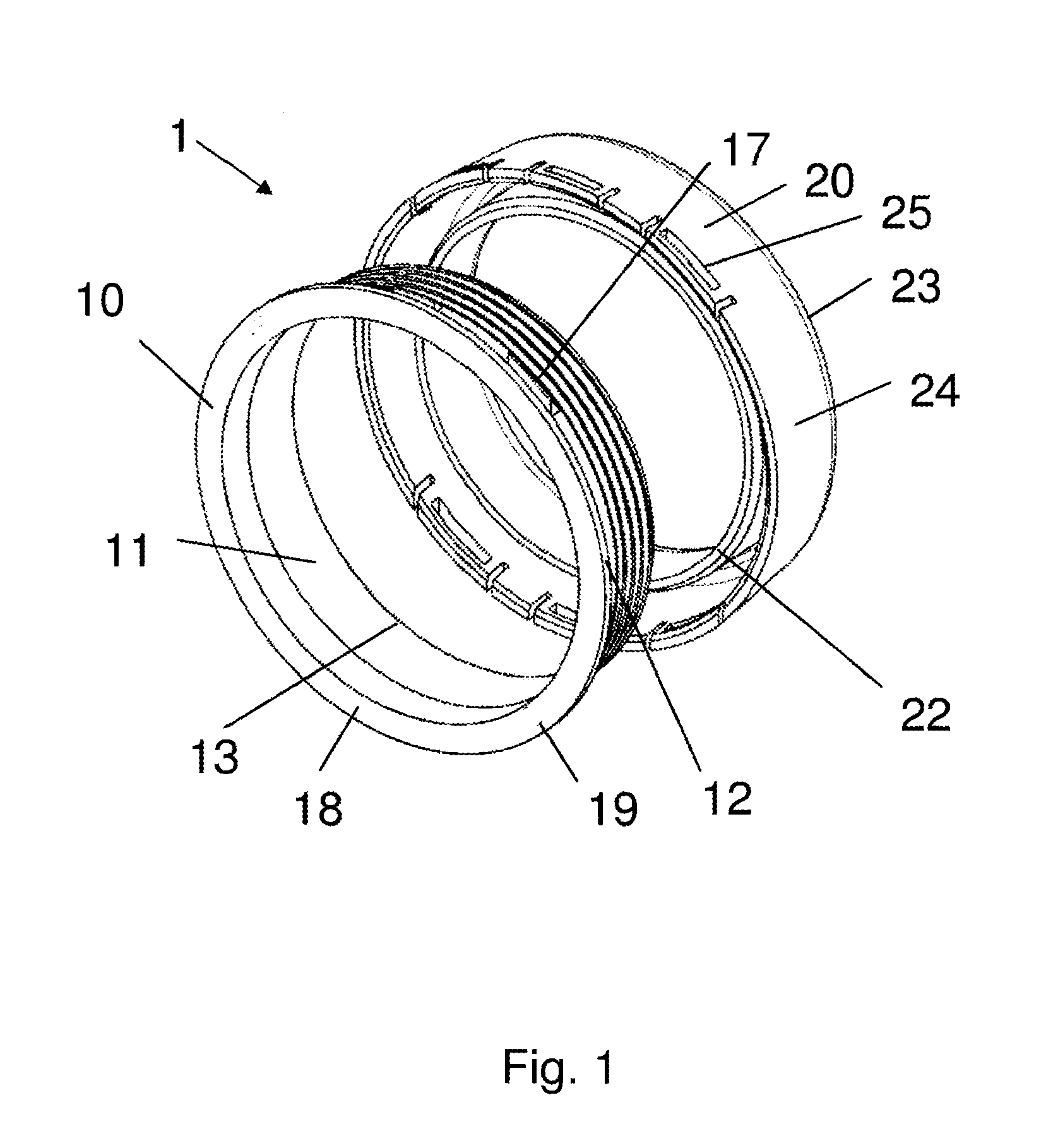

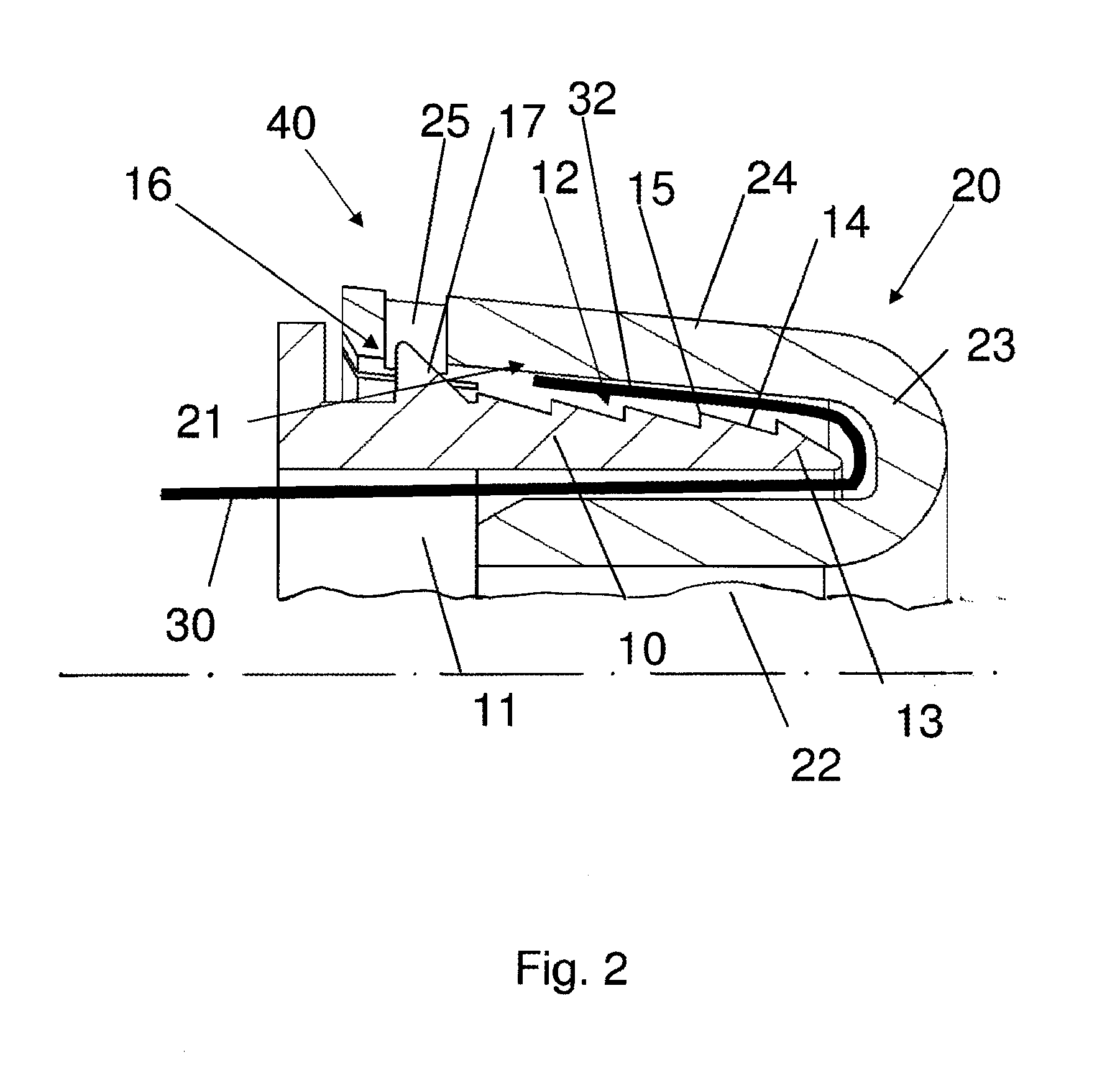

Adjustable tensioning system for rimless eyewear

InactiveUS7063420B2Minimize visual prominenceMinimize overlapSpectales/gogglesNon-optical partsEngineeringMechanical engineering

Eyewear has a wire that encircles each of a pair of lenses respectively. A tensioning assembly can adjust and tension the wire. Two variations of tensioning assemblies are shown. One tensioning assembly has a spool on which a portion of the wire is wound. Another tensioning assembly has an insert that pulls a portion of the wire inwardly within a projection that extends outward from the lens.

Owner:ISL TECH

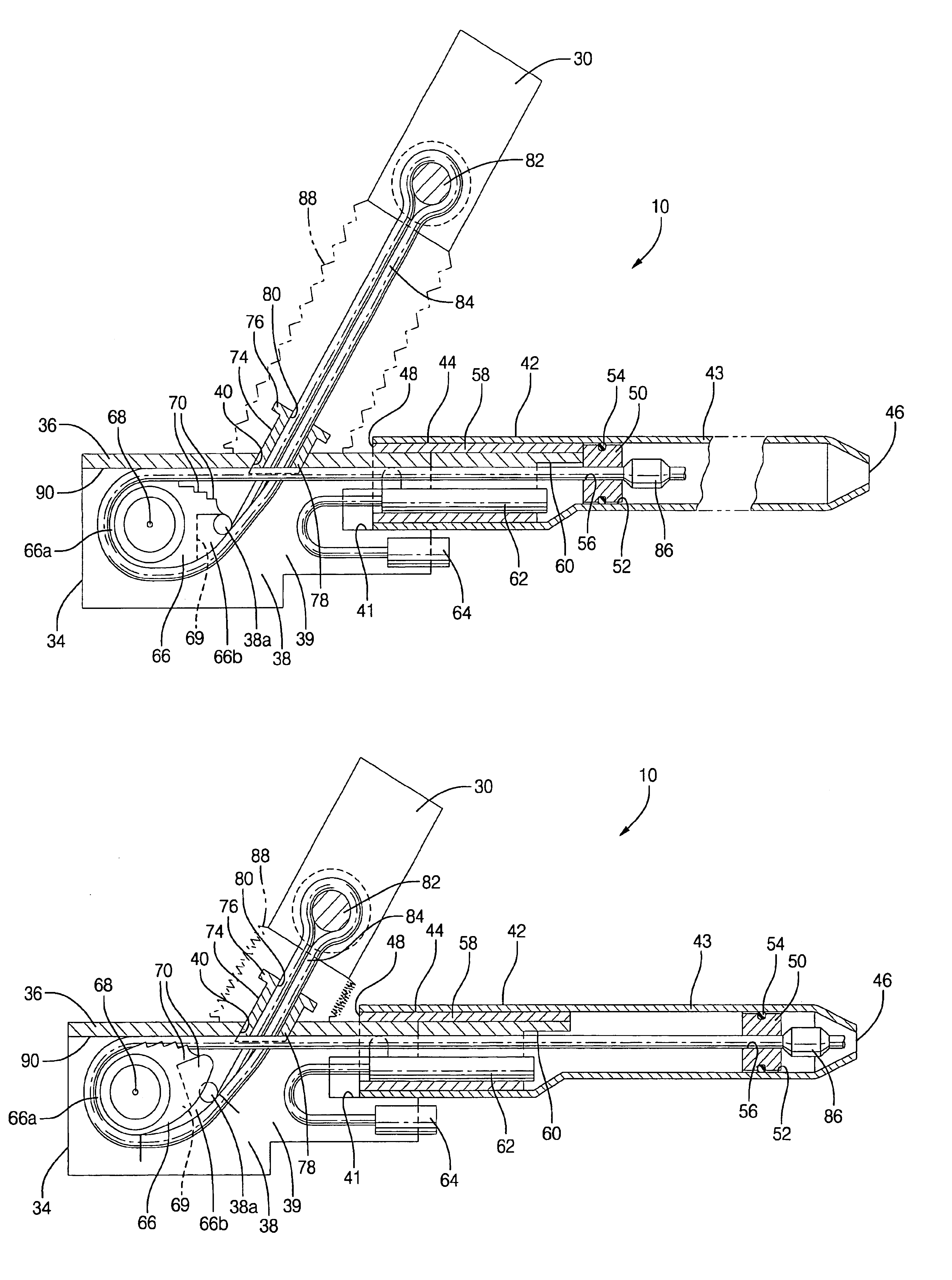

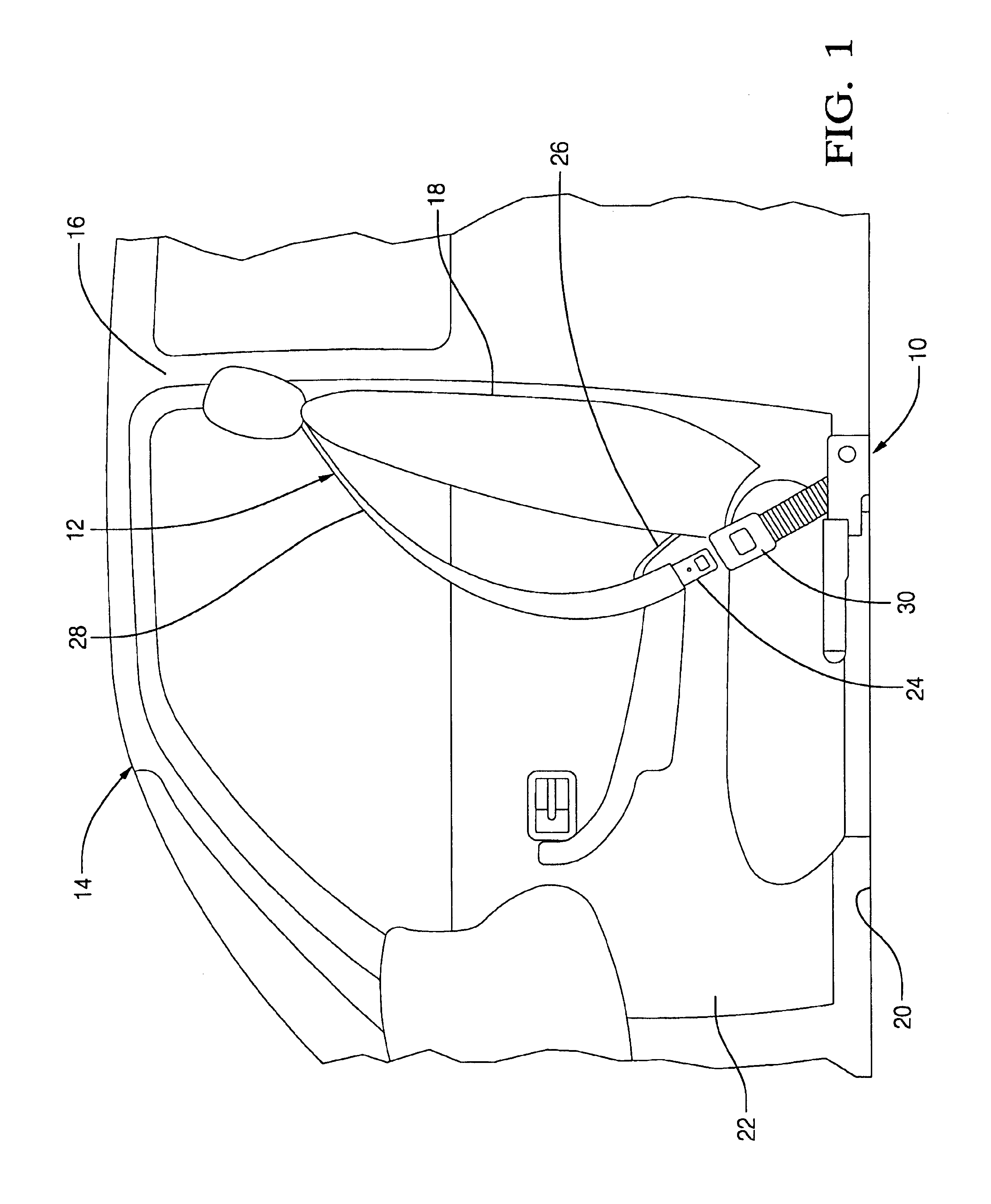

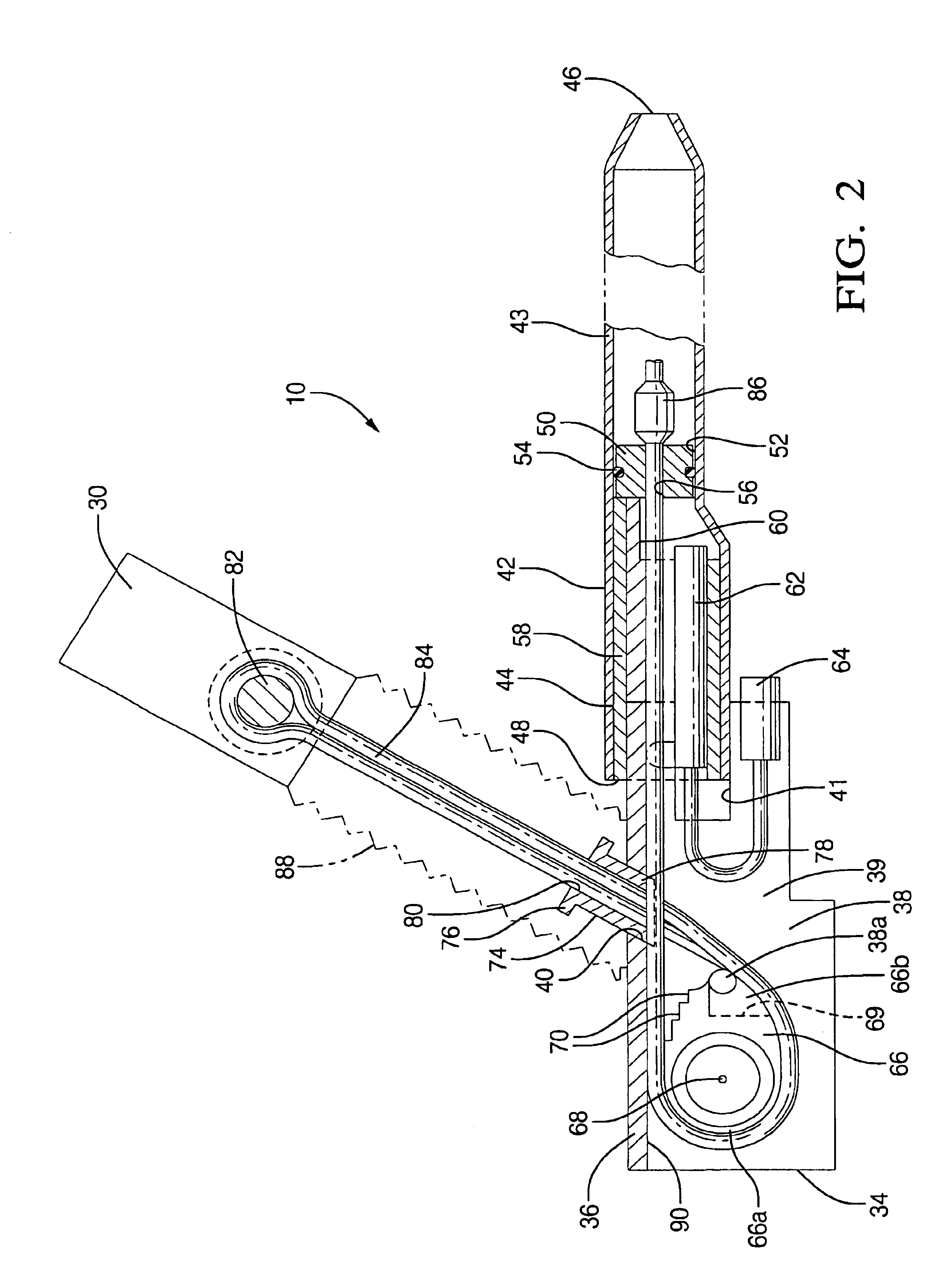

Seat restraint tensioner

A seat restraint tensioner for a seat restraint system in a vehicle includes a cable having a first end and a second end. The first end is operatively connected to a seat restraint of the seat restraint system. The seat restraint tensioner also includes a movable mechanism connected to the second end of the cable to apply a force for tightening the seat restraint when activated. The seat restraint tensioner further includes a rotatable cam cooperating with the cable to generate a clamping force toward the seat restraint to clamp the cable between the cam and a clamping surface to prevent reverse travel of the cable after tightening the seat restraint.

Owner:AUTOLIV DEV AB

Connector housing with integrated cable clamp

ActiveUS8246377B2Prevents the cable from turningIncrease the tensile loadRelieving strain on wire connectionMechanical engineeringEngineering

Owner:HARTING ELECTRIC GMBH & CO KG

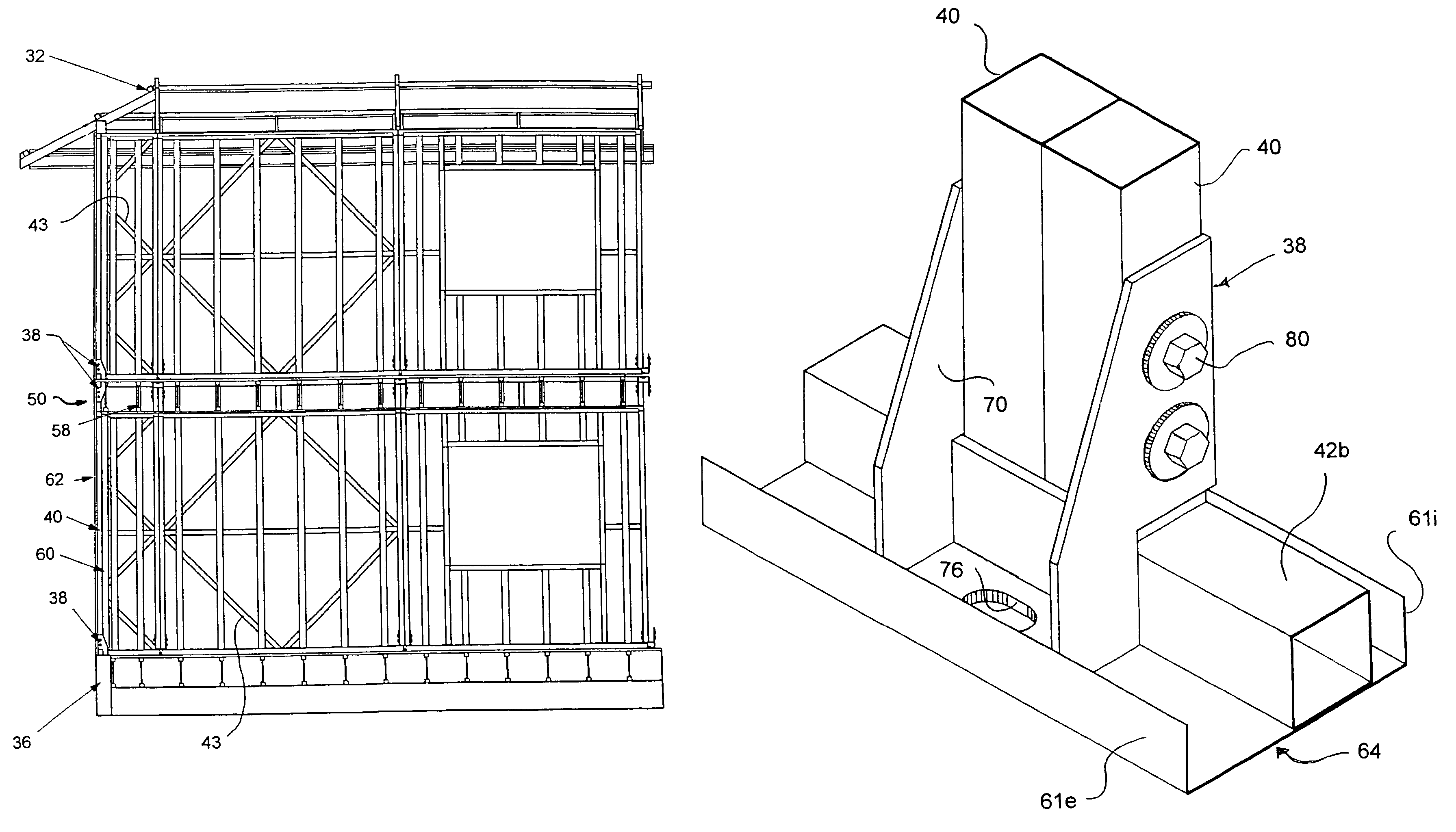

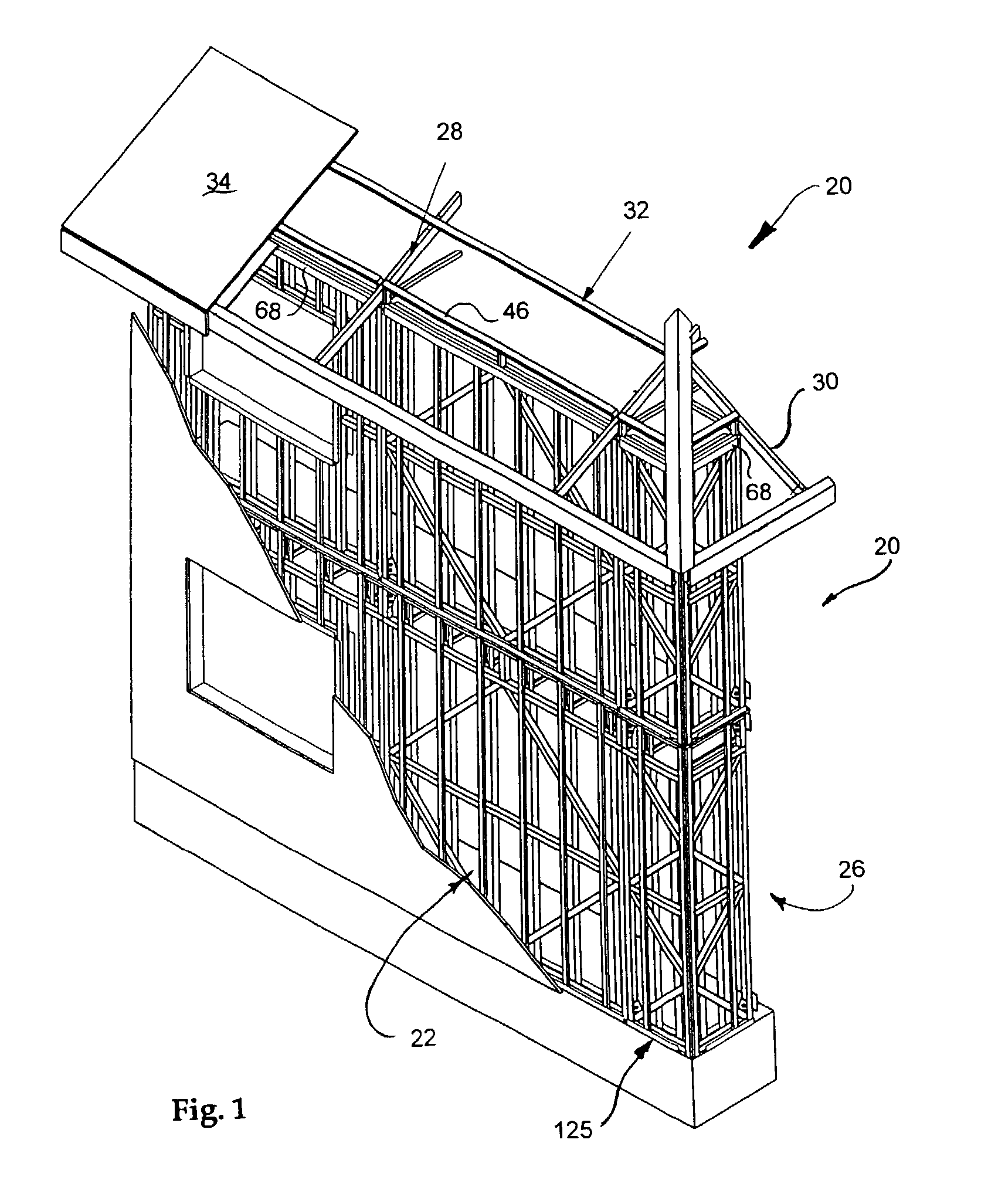

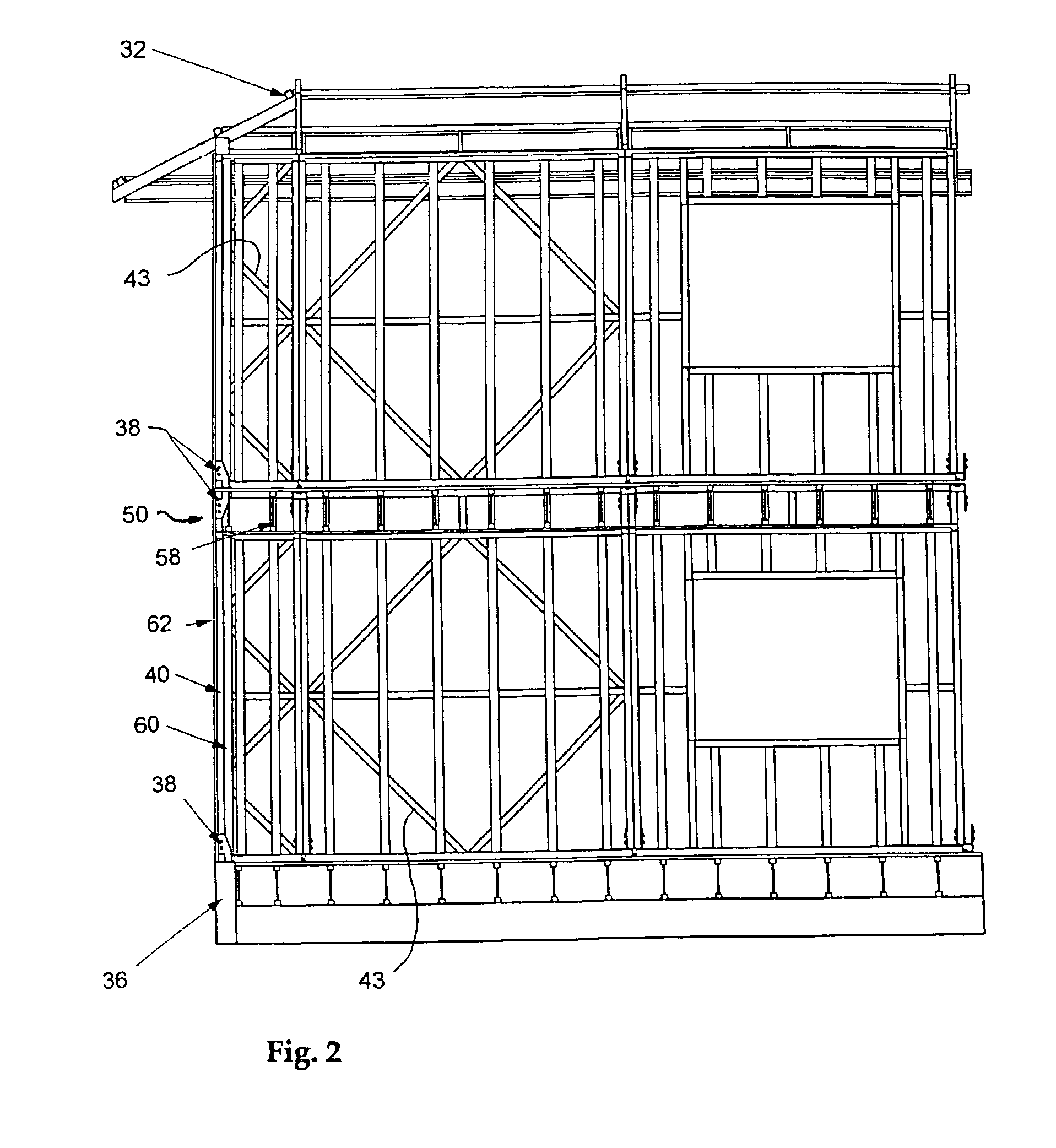

Modular building frame

ActiveUS7992352B2Simplify the finishing processLow costBuilding roofsPublic buildingsEngineeringWind force

A building frame resistant to earthquakes, gale-force wind loads, fire, insects and rot includes a peripheral frame wall constructed of rectangular steel tubing. Side wall frame modules and end wall modules bolted together along adjacent edges form the peripheral frame wall. Diagonal bracing is built into selected side and end wall modules as required for the desired degree of wind resistance. Trusses made of various size tube such as 2×3 inch rectangular steel tubing for supporting a roof, including a hip roof, on the peripheral wall, are assembled and welded in a welding shop and the prefabricated trusses and wall modules are trucked to the building site. Multiple stories may be erected and fastened together by anchor brackets arranged bottom-to-bottom above and below the second and higher floors. The building frame is secured to a foundation by attaching the anchor brackets to anchor bolts set in the foundation.

Owner:ALLIED TUBE CONDUIT +1

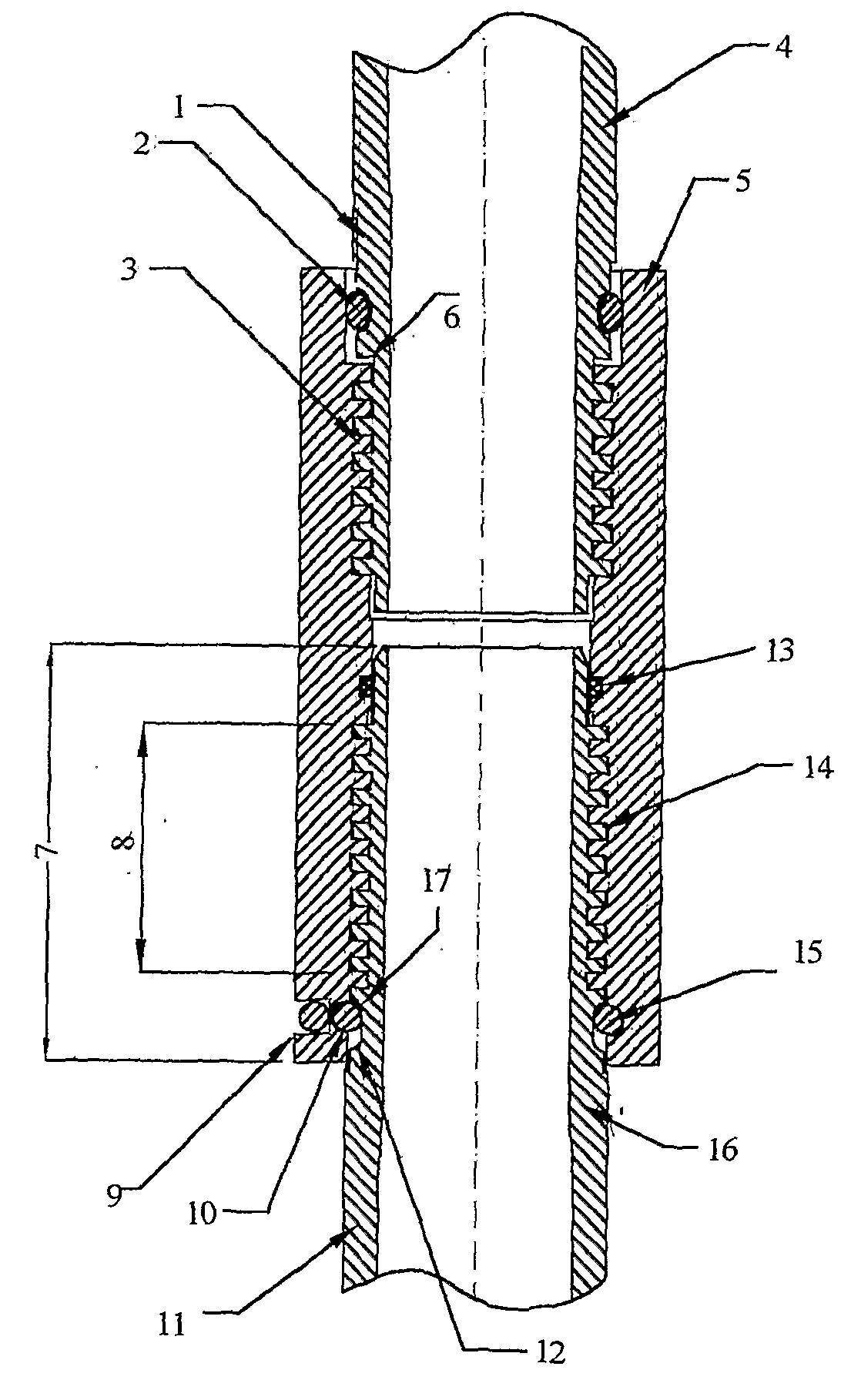

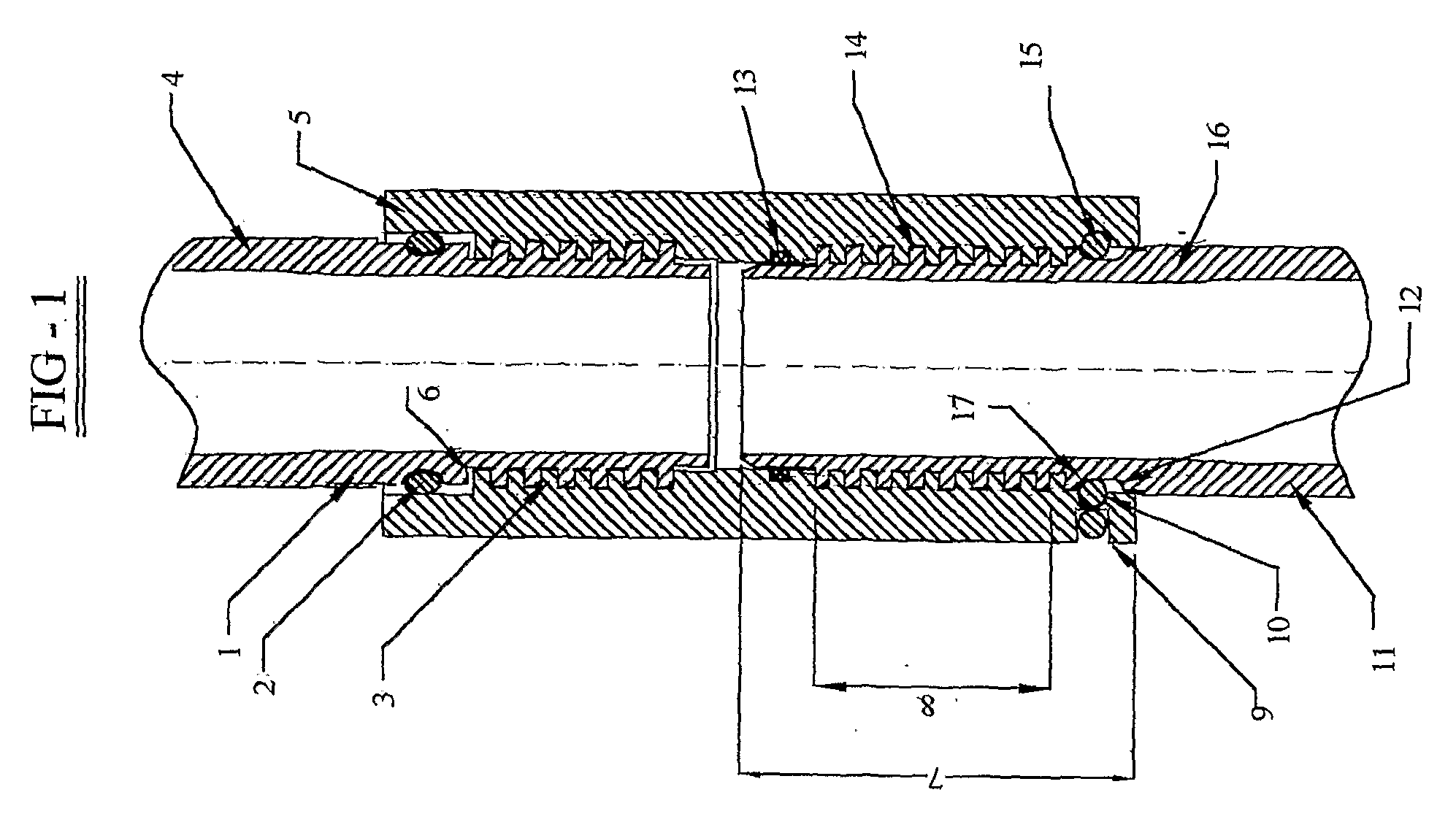

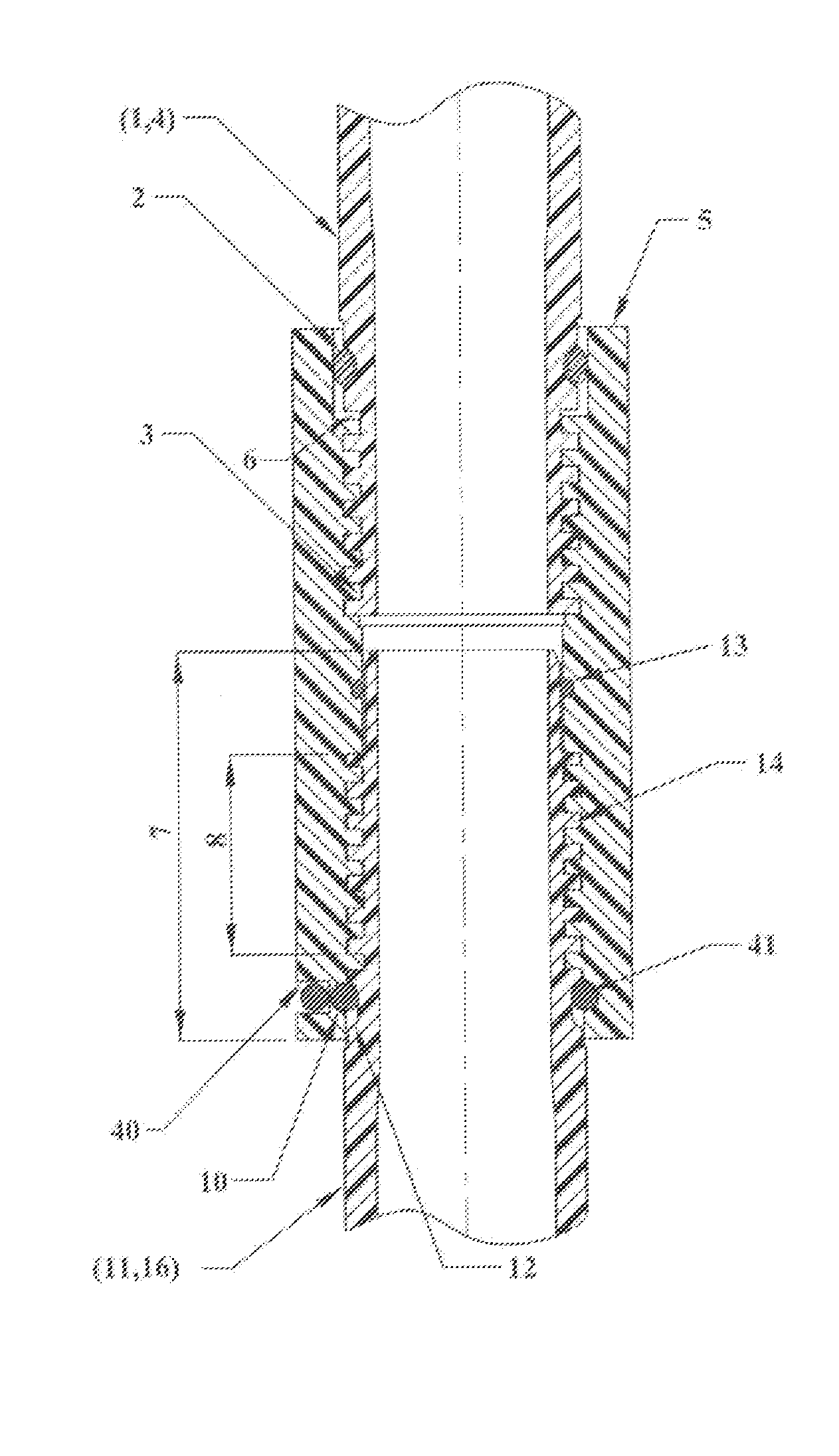

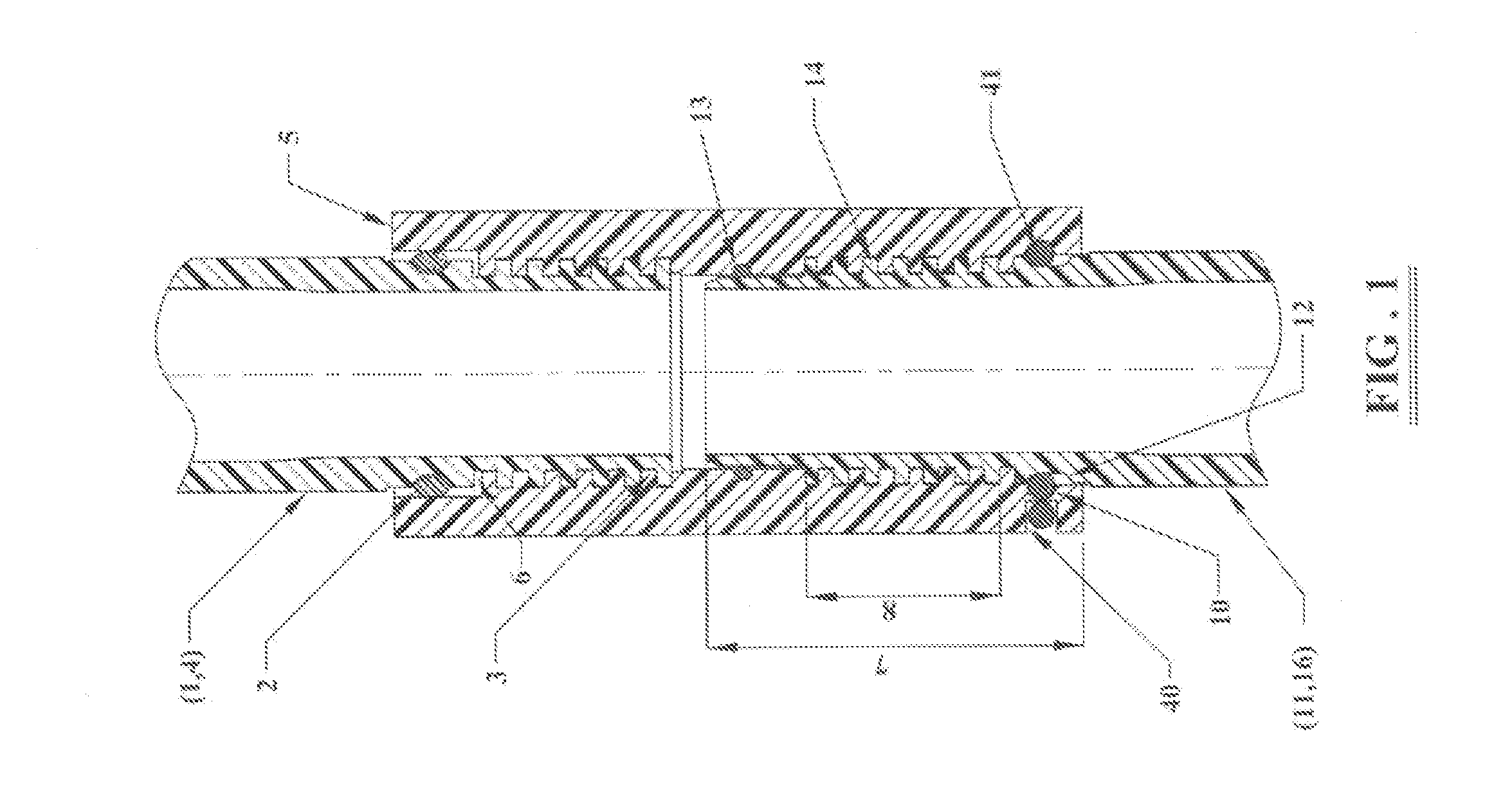

Threaded Pipe Joint Coupling With Wire Lock Device

InactiveUS20080067808A1Improve carrying capacityIncrease the tensile loadEngine sealsPipe elementsCouplingThreaded pipe

A Polyvinyl Chloride Threaded Pipe Joint System With Coupler & Wire Locking device comprising two pipe joining components, two sealing rings, including a wire lock, the said wire lock is component being inserted into the groove which locks the coupling with the one end of the pipe joint, the said coupling joining the both the ends using the threads, the said threads are made in the form of square type threads and the said sealing rings are fixed to the both the ends of the pipes and coupler.

Owner:ASHIRVAD PIPES PTV LTD

Adjustable tensioning system for rimless eyewear

InactiveUS20050253999A1Minimize visual prominenceMounting structure can be loweredSpectales/gogglesNon-optical partsWire rod

Eyewear has a wire that encircles each of a pair of lenses respectively. A tensioning assembly can adjust and tension the wire. Two variations of tensioning assemblies are shown. One tensioning assembly has a spool on which a portion of the wire is wound. Another tensioning assembly has an insert that pulls a portion of the wire inwardly within a projection that extends outward from the lens.

Owner:ISL TECH

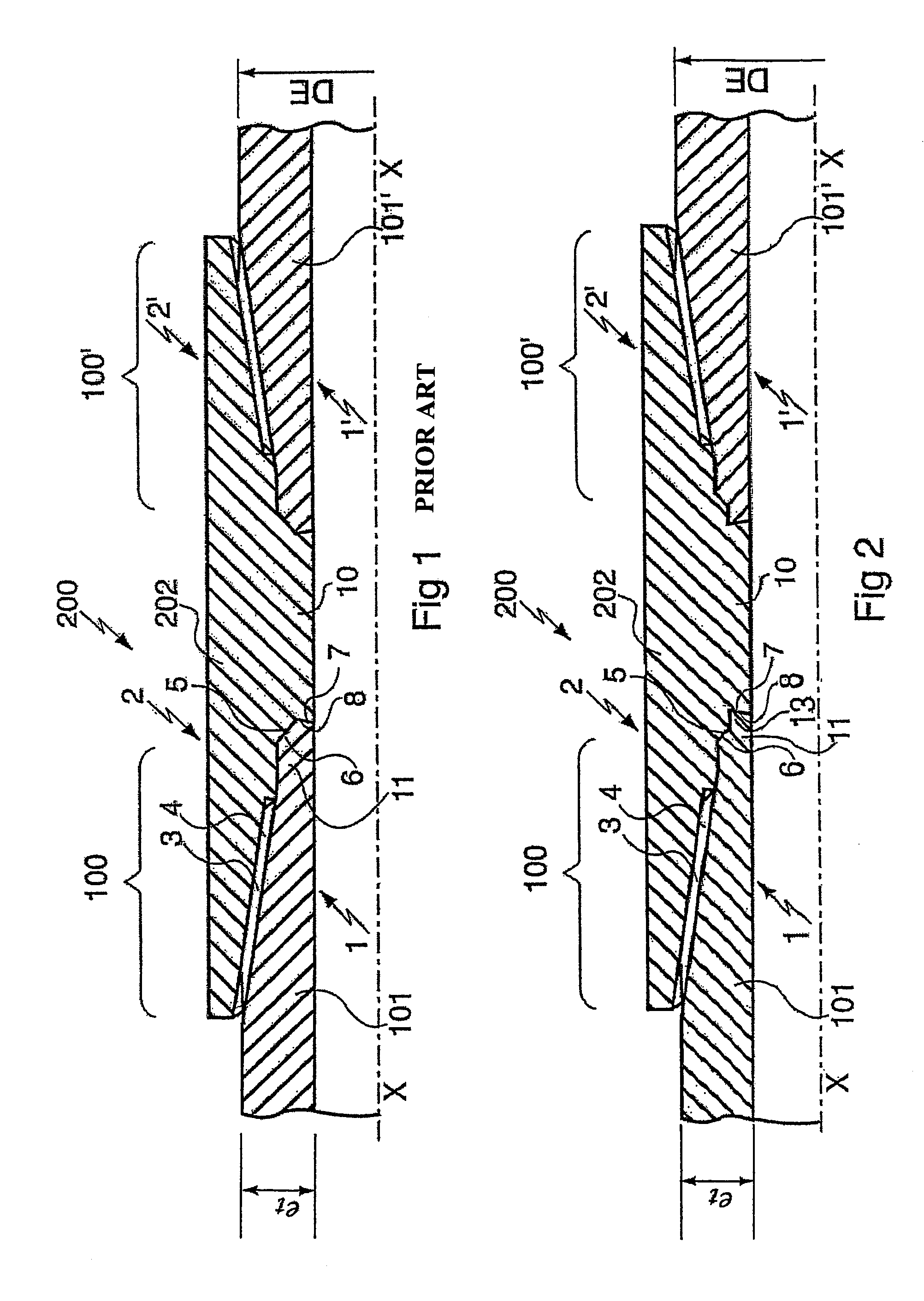

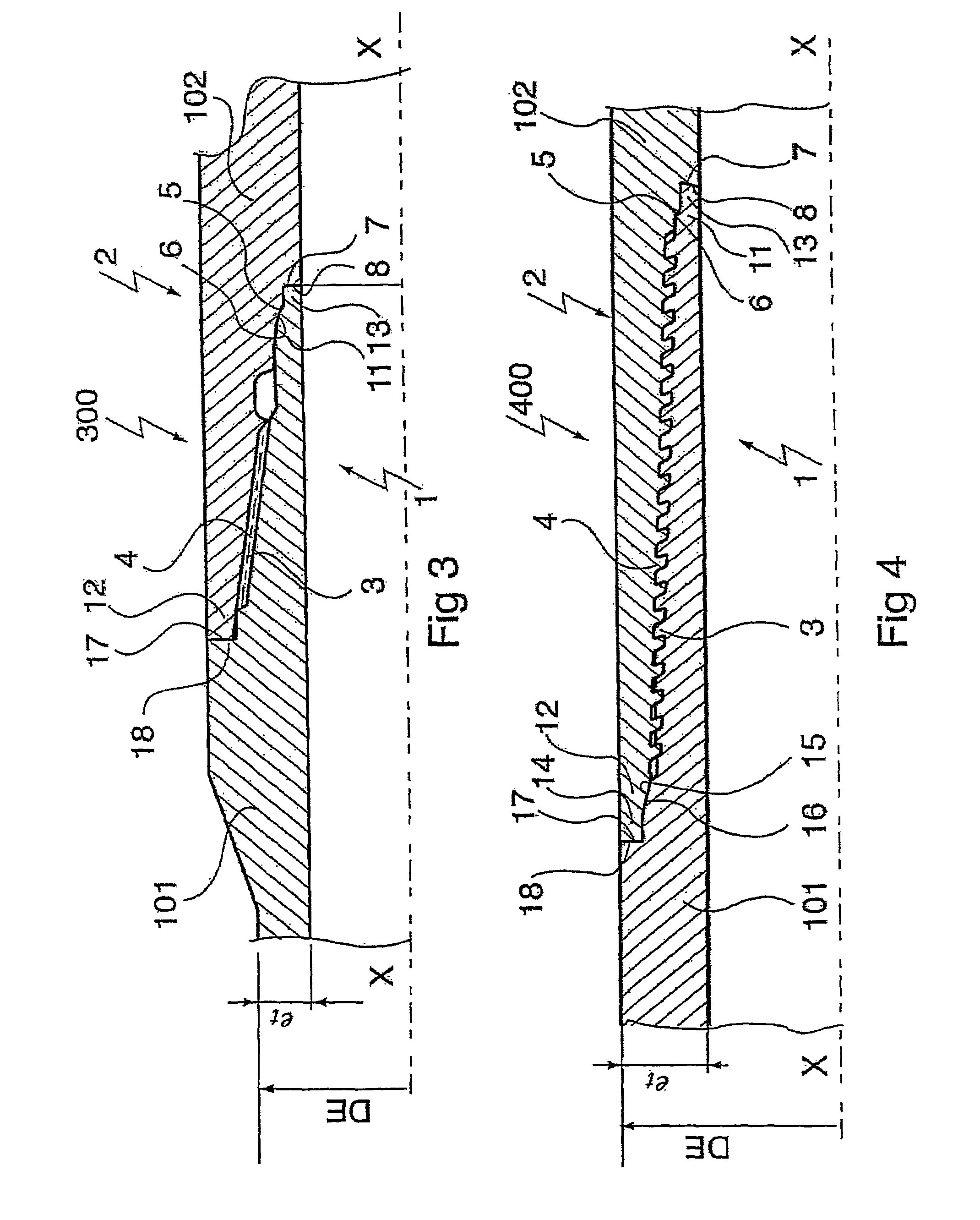

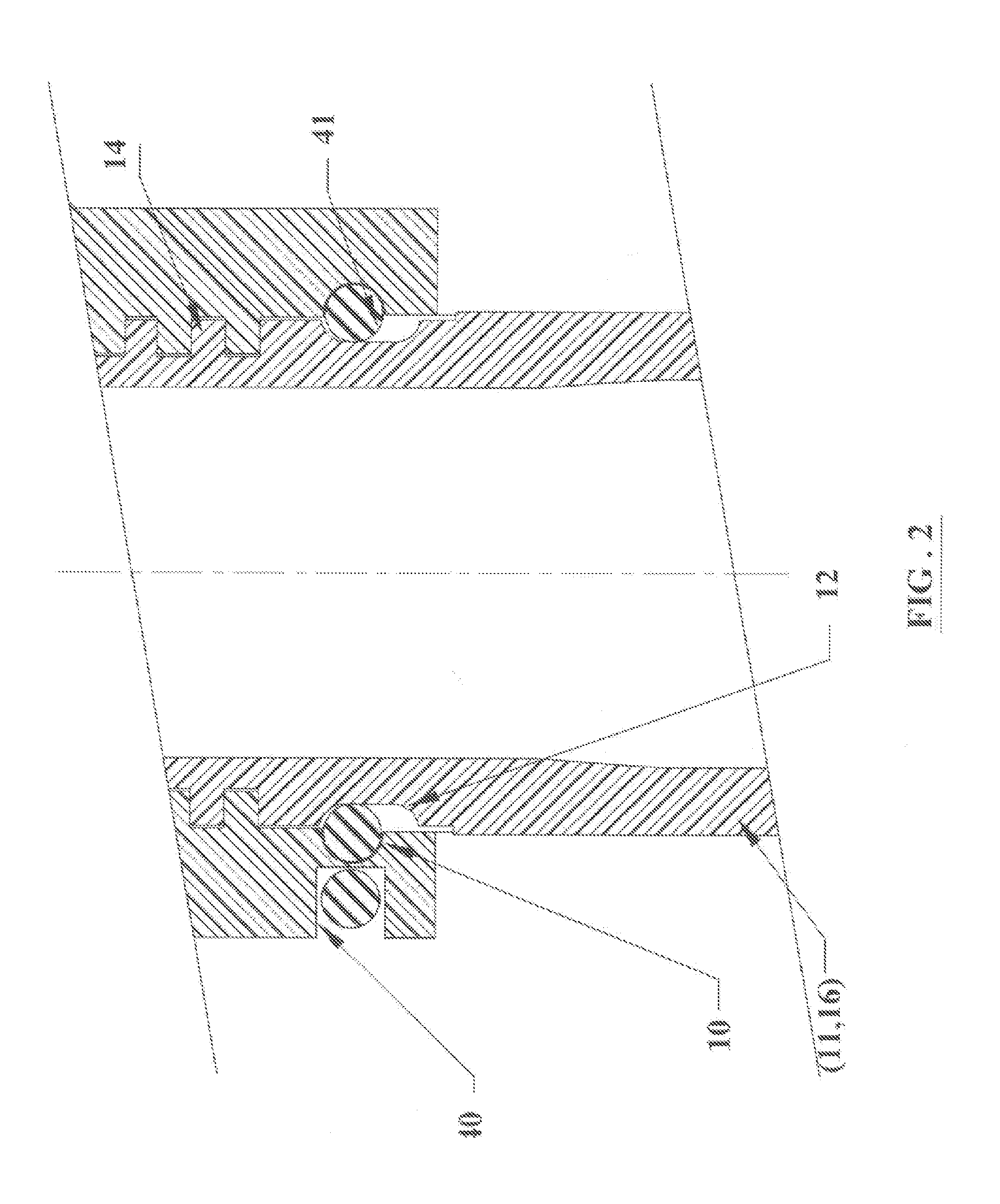

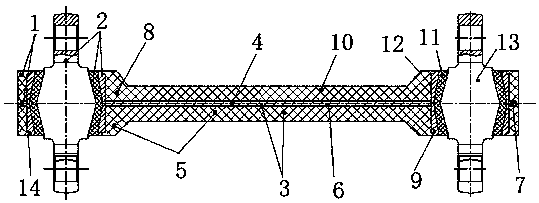

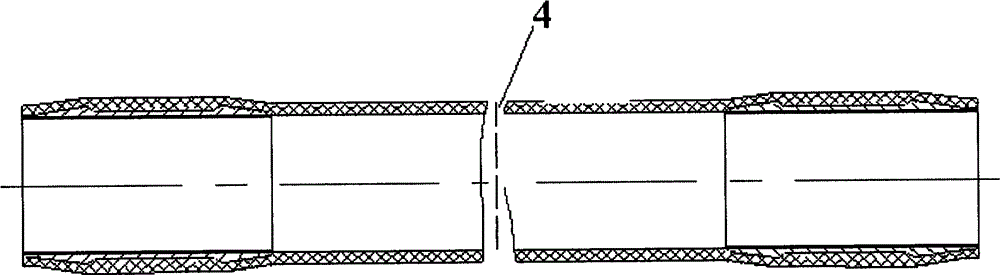

Threaded pipe joint coupling with wire lock device

InactiveUS8246084B2Increase the tensile loadSolve insufficient capacityPipe elementsCouplingsCouplingThreaded pipe

A threaded pipe (11) and coupler (5) made of polyvinyl chloride, the coupler (5) comprising two coupling ends having inner square-shaped threading (3, 14), each receiving a pipe end (4, 11) having an outer square-shaped threading, a sealing ring (2, 13) being provided between each coupling end of an inner surface of the coupler (5) and an outer surface of the corresponding pipe end (4, 11); a groove (10), being formed on the inner surface of the coupler (5), and co-operating with a part of the outer surface of the pipe end after the threading, when the pipe (11) is threadingly coupled in the coupler (5), to form a tangential hole (42) between the outer surface of the pipe (11) and the inner surface of the coupler (5) with the groove made on the outer surface of the coupler aligning with a groove of first pipe, wherein a wire lock (41) is inserted in the tangential hole (42) to lock the coupling of the coupler (5) with the end of the pipe (11).

Owner:ASHIRVAD PIPES PTV LTD

Connecting Socket for Filter Hoses

ActiveUS20120267891A1Low production costStable and connection of and connectingSleeve/socket jointsFluid pressure sealed jointsEngineeringMechanical engineering

Owner:MANN HUMMEL GMBH

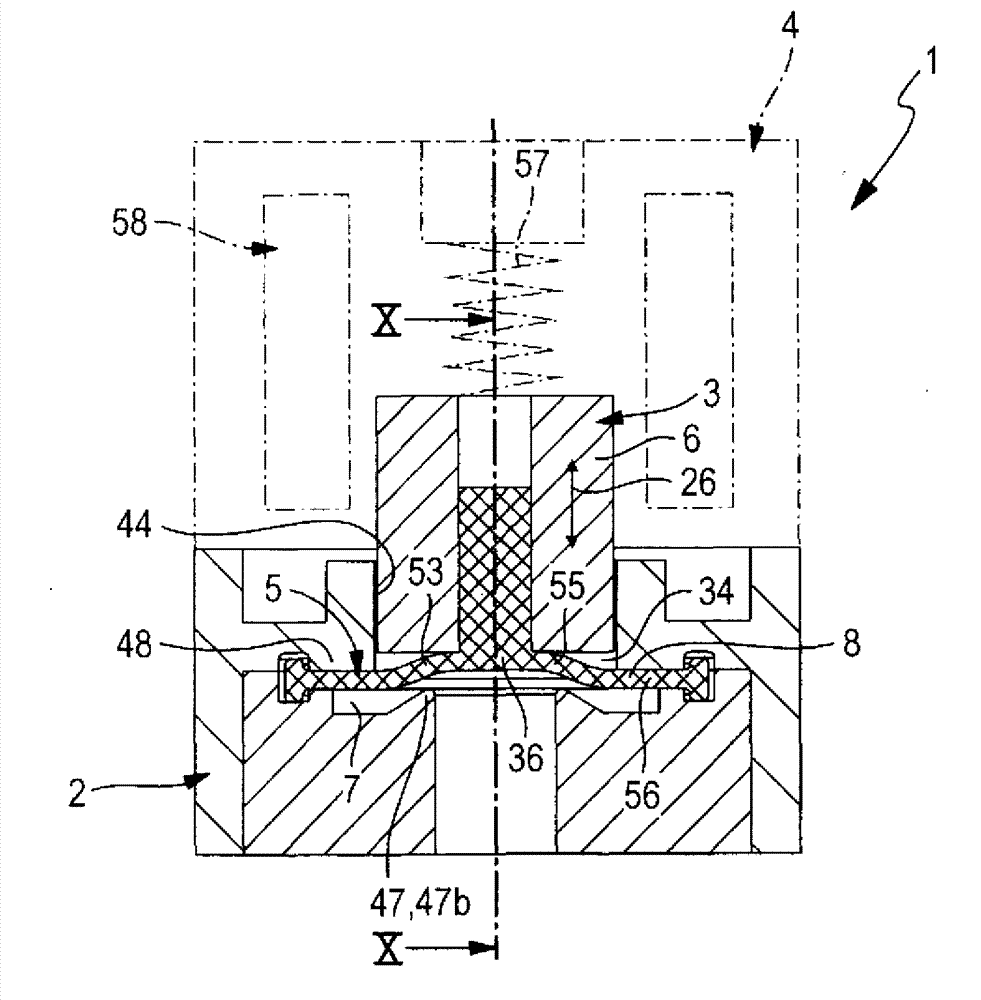

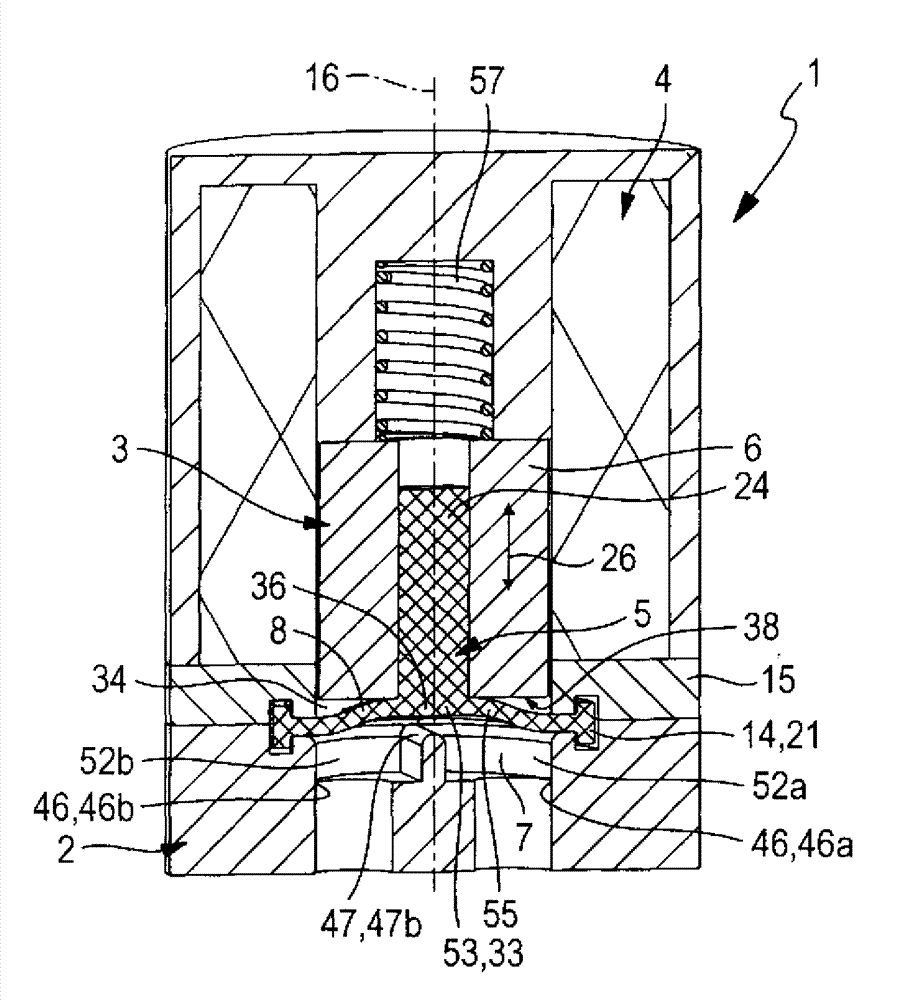

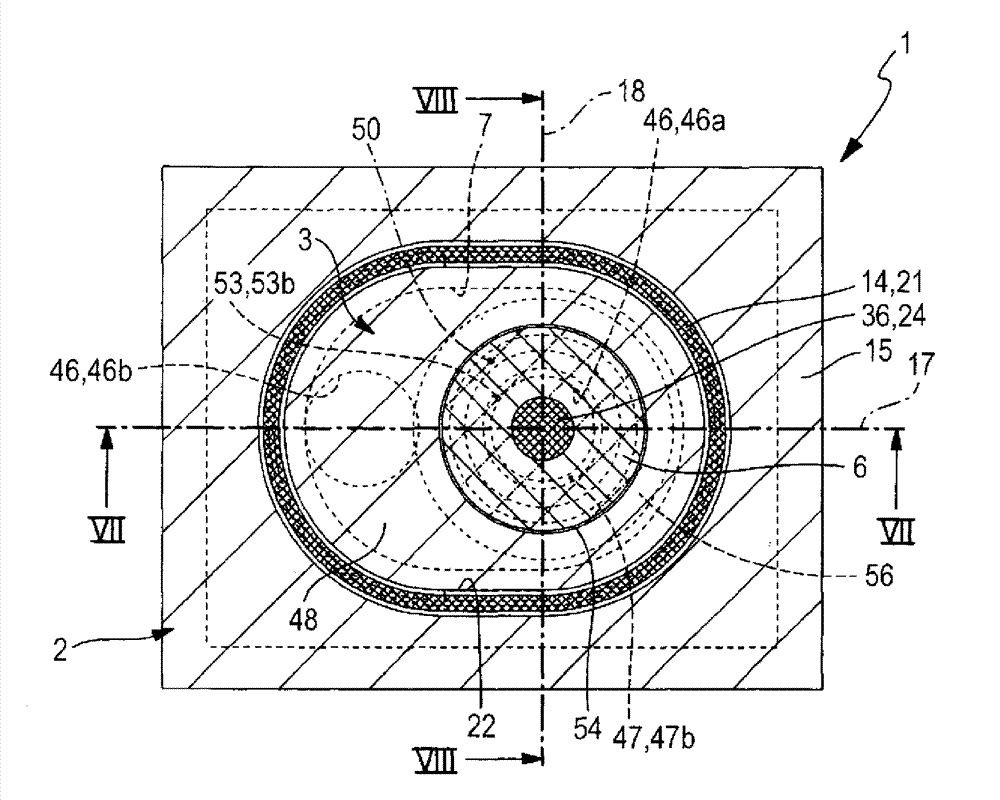

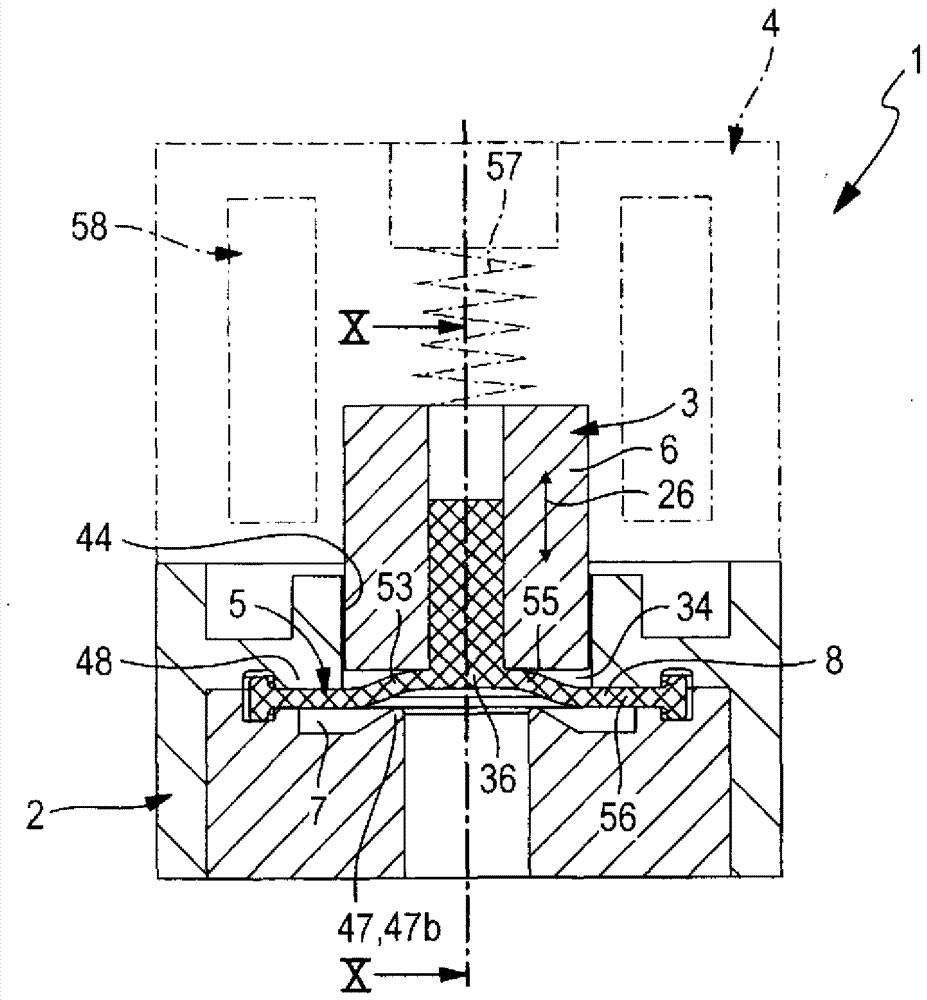

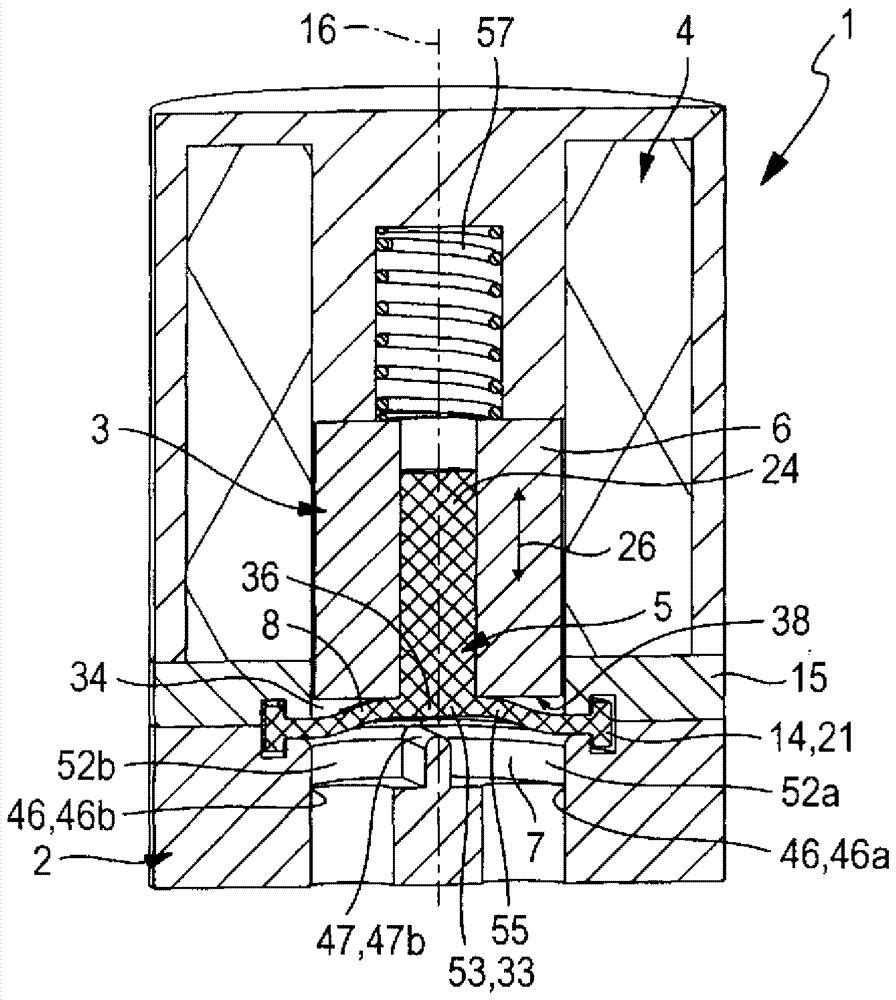

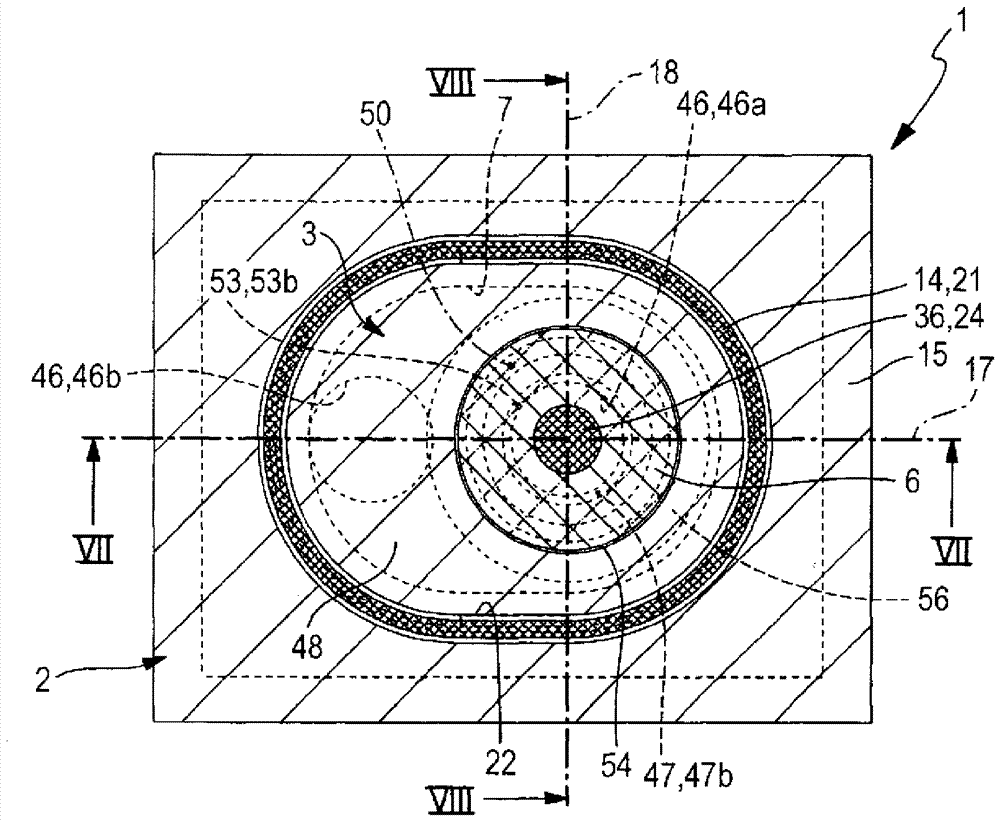

Diaphragm valve

ActiveCN104302957AExtend your lifeIncrease the tensile loadDiaphragm valvesOperating means/releasing devices for valvesDiaphragm valveEngineering

The invention relates to a diaphragm valve (1) having a valve housing (2) and a valve member (3) movable relative to said housing. The valve member (3) comprises a diaphragm carrier (6) that can be driven to execute a switchover motion (26) having a sealing diaphragm (8) mounted thereon, which delimits a valve chamber (7) in which a valve seat (47) is found. The sealing diaphragm (8) has a sealing section (53) opposite said valve seat (47) belonging at least partially to a loose diaphragm section (55) of the sealing diaphragm (8), which can lift from the diaphragm carrier (6) to reduce the stress on the sealing diaphragm (8) when said diaphragm carrier is removed from the valve seat (47) during switching.

Owner:FESTO AG & CO KG

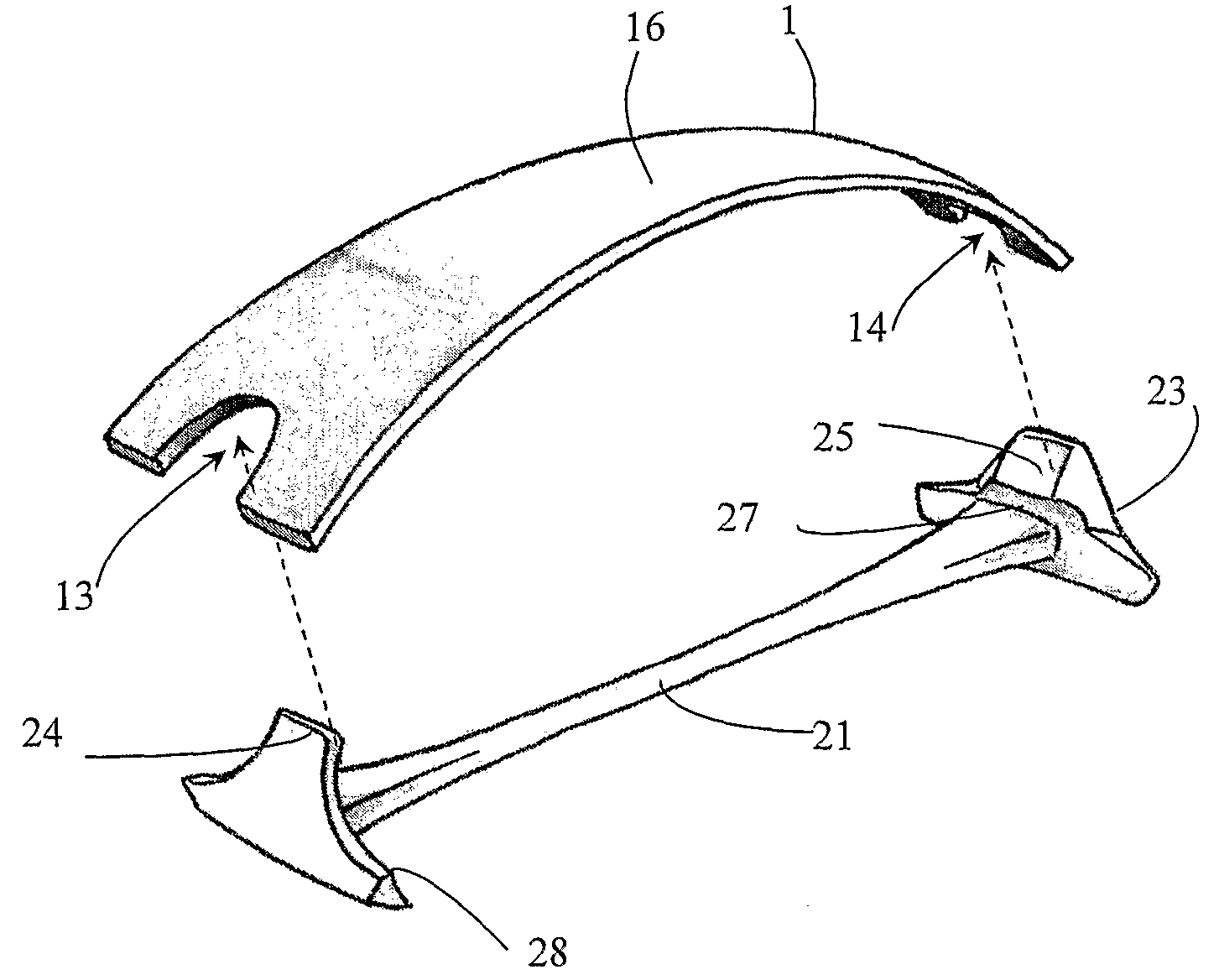

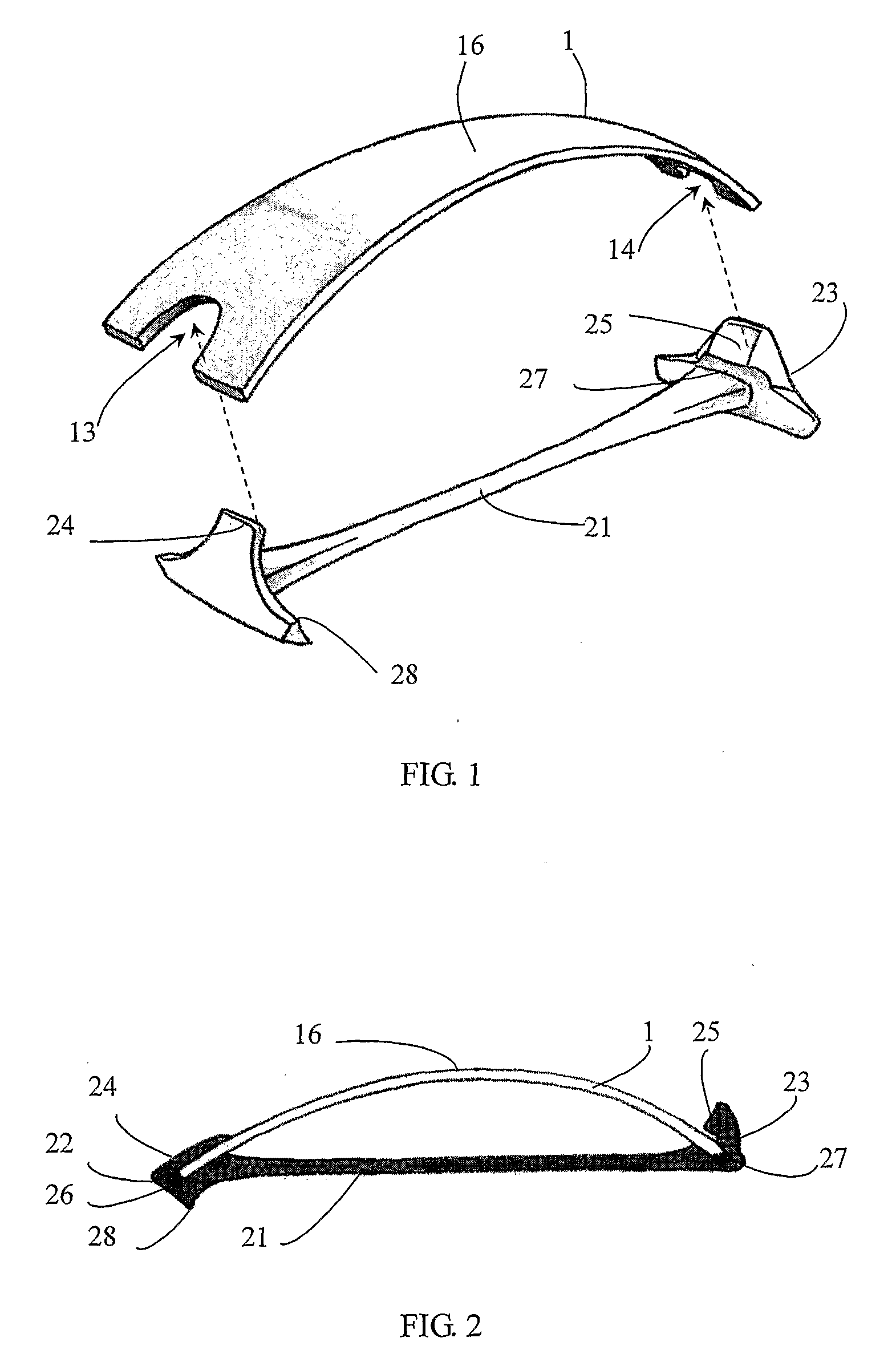

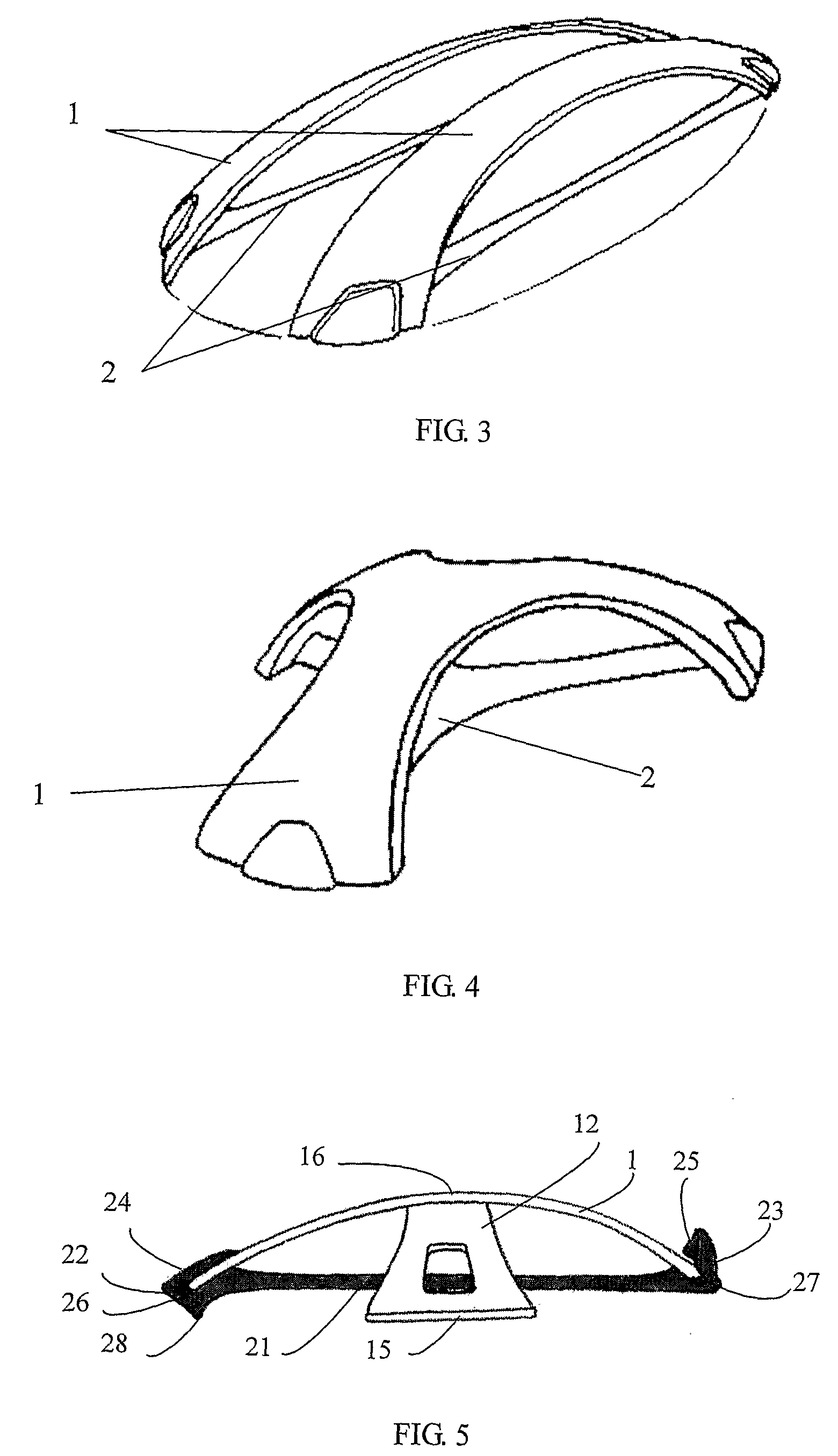

Adjustable Shock Attenuating Means for Footwear and Footwear Using the Same

An adjustable shock attenuating means comprises at least one arch element (1) and at least one tensile element (2) arranged between any two positions at a concave surface of the element (1) or between two ends of the arch element (1). This means further comprises at least one additional arch element (12) arranged intersecting with the arch element (1) or arranged with the arch element (1) side by side. The arch element (1) has a U-shaped cut-out (13, 14) at its two ends respectively and the tensile element (2) correspondingly has a connecting piece (23, 24) at its two ends respectively to be coupled with the U-shaped cut-outs (13, 14) of the arch element (1) with which the tensile element (2) is coupled with the arch element (1).

Owner:LI NING SPORTS SHANGHAI

Extraction device for extracting a trim weight from a rotor blade

InactiveUS20170305003A1Easy and safe and reliableEasy and uncomplicated accessSpannersWrenchesEngineeringScrew thread

An extraction device for extracting a trim weight from a rotor blade, comprising a supporting tube that is at least partly provided with a female thread, and a threaded rod that is at least partially arranged in the supporting tube, wherein the threaded rod is coupled to a fixing element that is adapted for being detachably fixed to the trim weight and that is at least partially provided with a male thread which engages at least partially the female thread of the supporting tube, and wherein the threaded rod is at least partly plastically deformable.

Owner:AIRBUS HELICOPTERS DEUT GMBH

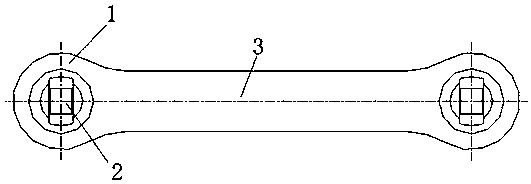

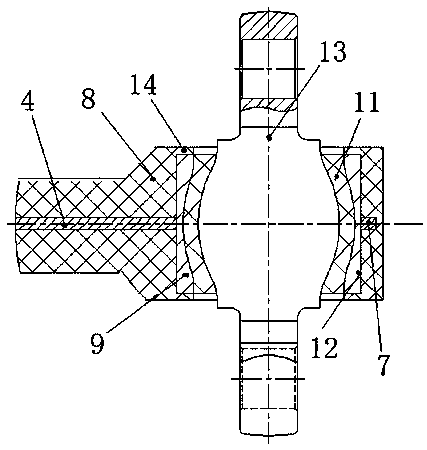

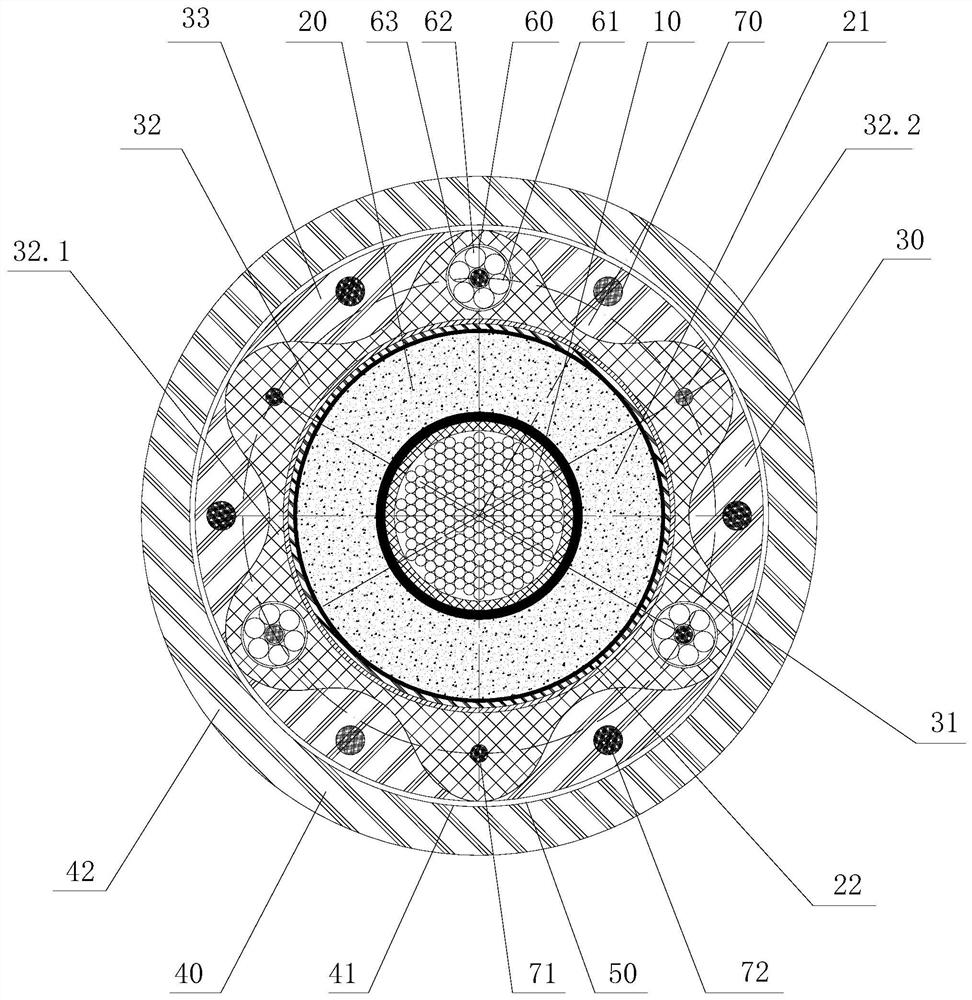

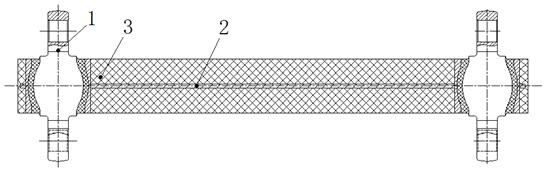

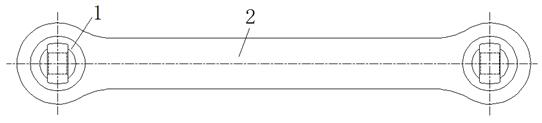

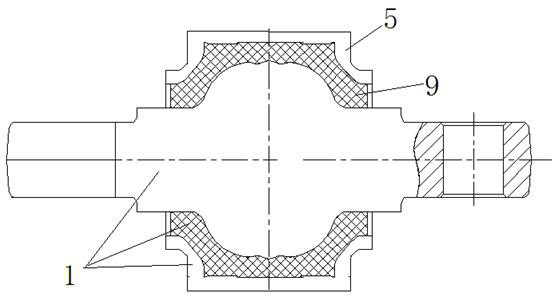

Light-weight method of elastic connecting rod with rubber metal ball hinge

InactiveCN110594329AImprove carrying capacityIncrease the scope of applicationSuspensionsConnecting rodsMolecular materialsUltimate tensile strength

The invention discloses a light-weight method of a connecting rod with a rubber metal ball hinge. The rubber metal ball hinge is mounted in a joint at one end or two ends of the connecting rod, and the joint of the connecting rod is wrapped around the rubber metal ball hinge; a connecting rod body and the joint are made from a light-weight high-molecular material, a reinforcing body which is higher in strength than a light-weight base body material of the connecting rod body and the joint are embedded into the connecting rod body and a joint base body which are made from the light-weight high-molecular material, the light-weight connecting rod body and the joint which are manufactured in a composite mode by adopting the reinforcing body and the light-weight high-molecular material is wrapped around the rubber metal ball hinge, the reinforcing body bears the tensile load in the direction of the rod body, and the connecting rod body and the joint base body which are manufactured from thelight-weight high-molecular material bear the compressive load and the tensile load in the direction of the rod body, so that the overall tensile strength of the connecting rod is enhanced. Accordingto the light-weight method, two materials are compounded to manufacture the light-weight joint and the connecting rod body, so that the bearing capacity of a product in the main bearing direction isimproved, and the bearing and application range of a thrust rod is improved.

Owner:BOGE RUBBER&PLASTICS ZHUZHOU CO LTD

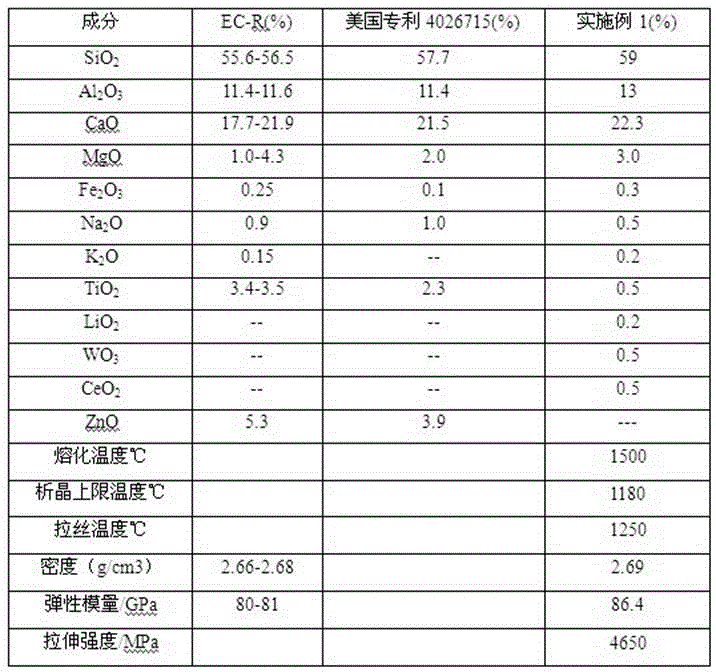

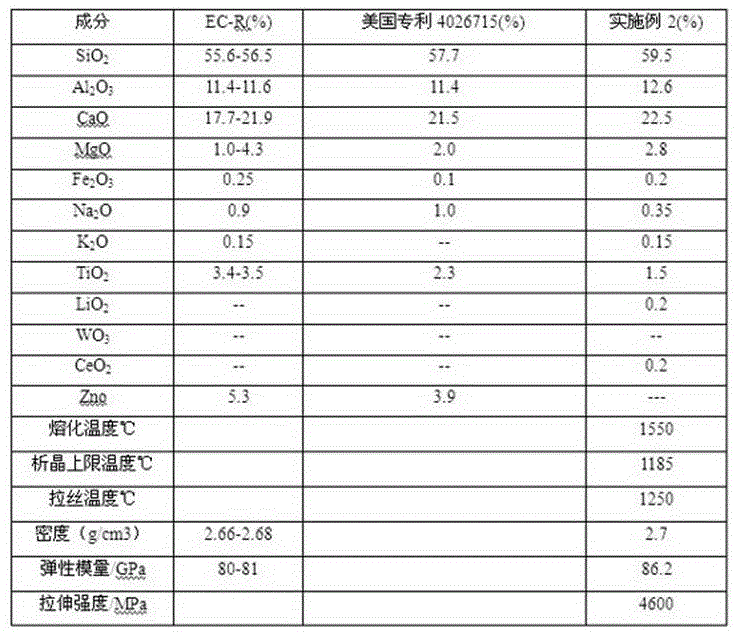

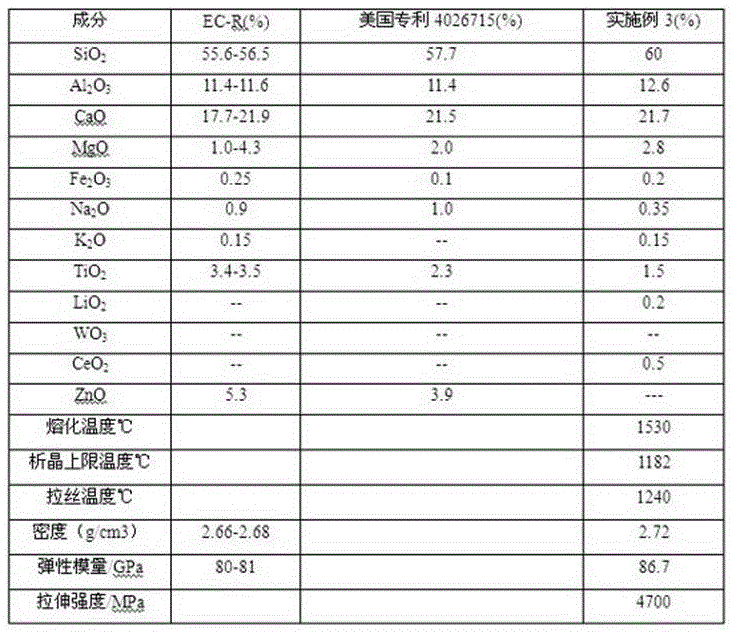

A kind of production process of high modulus non-alkali glass fiber

Owner:江苏九鼎特种纤维有限公司

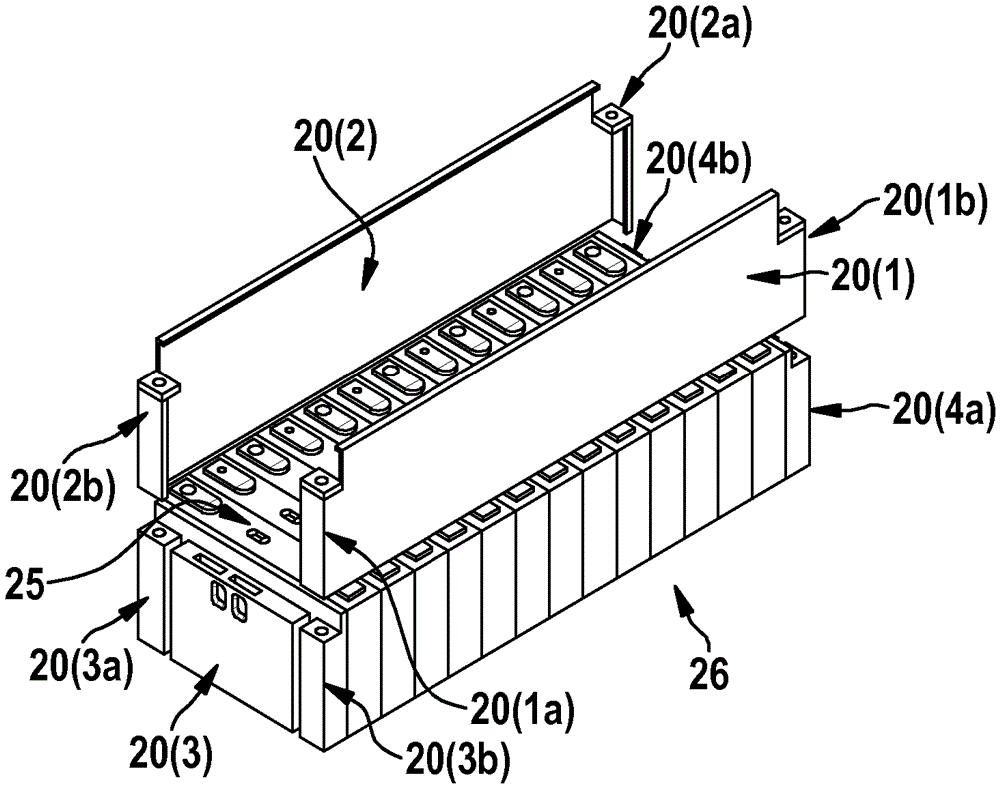

Retaining device for at least one battery cell

InactiveCN105431963APrevent slippingReduce weightCell component detailsBatteriesBattery cellElectrical and Electronics engineering

The invention relates to a retaining device for at least one battery cell, wherein the retaining device comprises at least two retaining elements, each retaining element comprises at least one fastening means, and the at least two retaining elements are mechanically detachably connected by means of the fastening means.

Owner:ROBERT BOSCH GMBH

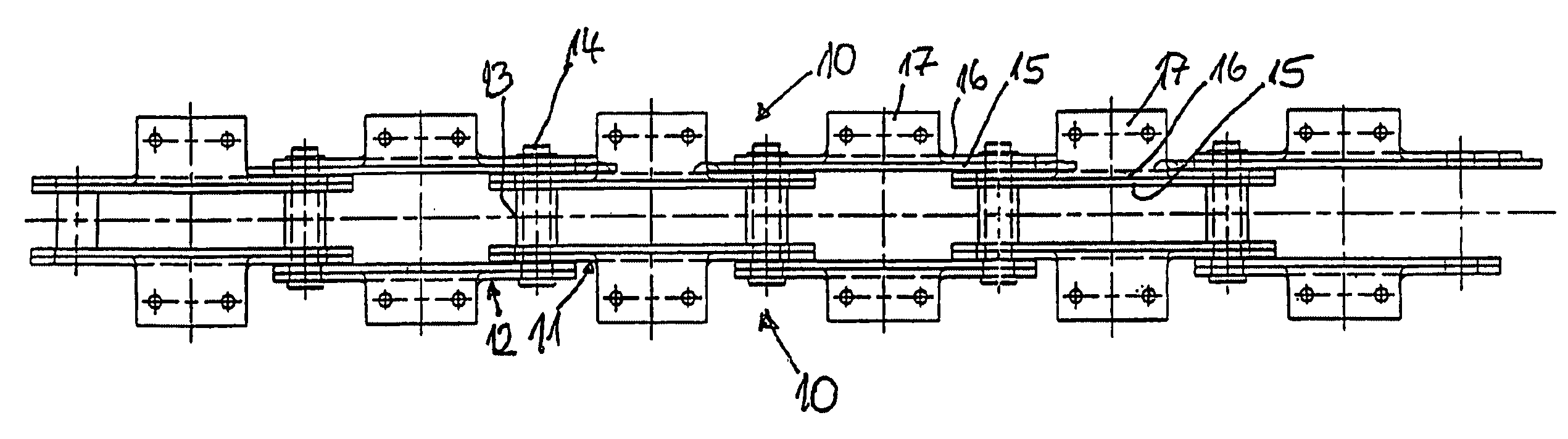

Plate link chain having inner and outer plate members

ActiveUS7293643B2Facilitate manufacturingThickness of material be therefore limitedConveyorsDriving chainsEngineeringMechanical engineering

Owner:AUMUND FORDERTECHN

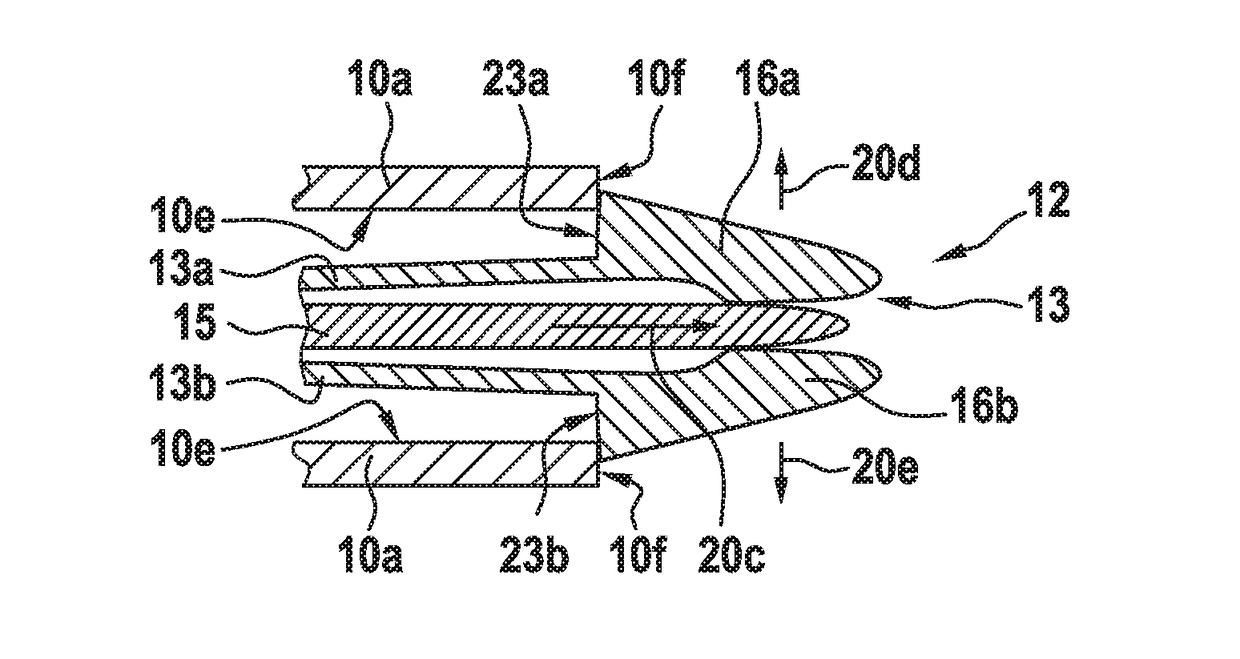

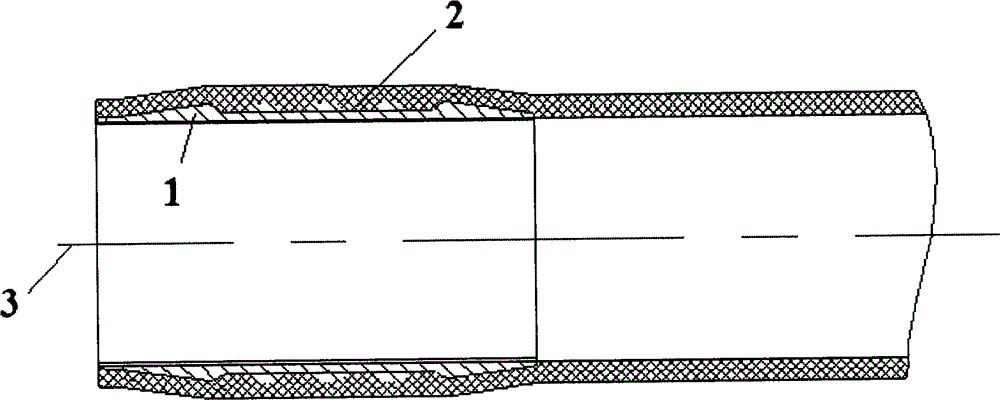

A kind of high tensile load composite material pipe fitting and its preparation method

ActiveCN102913744BReduced tendency to early failureIncrease the tensile loadElongated constructional elementsPipe fittingEngineering

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

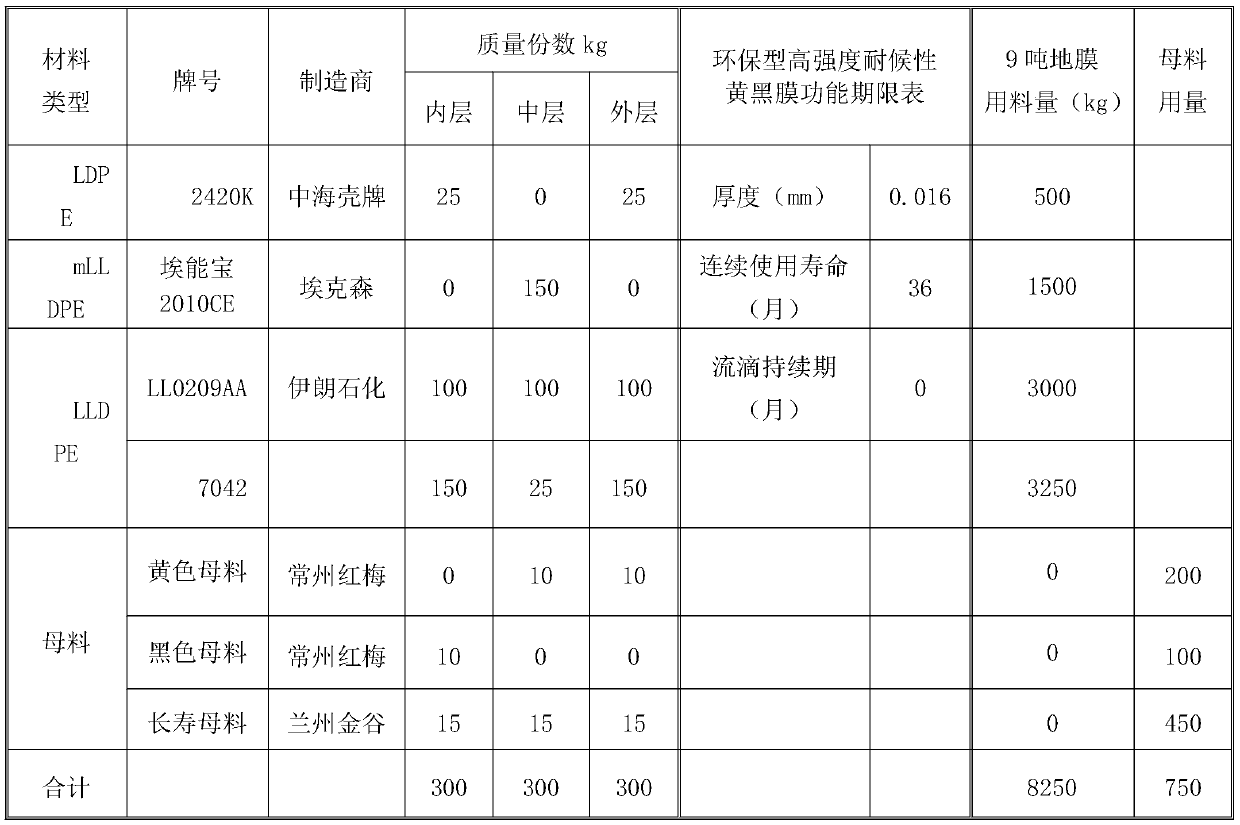

Plastic woven bag with high tensile load

InactiveCN109111638AIncrease the tensile loadHigh breaking strengthConjugated synthetic polymer artificial filamentsArtifical filament manufactureLinear low-density polyethyleneDecabromodiphenyl ether

The invention discloses a plastic woven bag with high tensile load. The plastic woven bag is prepared from the following components in parts by weight: 50-70 parts of linear low-density polyethylene,22-25 parts of phenolic resin, 20-25 parts of polyoxymethylene, 2-5 parts of clay, 1-3 parts of alums, 2-3 parts of hexanediol diacrylate, 4-5 parts of actinolite, 1.5-3 parts of ferrocene, 1.5-2.5 parts of vanadium diboride, 0.5-1.5 parts of decabromodiphenyl ether, 1-3 parts of butyl tin oxide, 4.3-4.5 parts of dimethyl aminoethyl acrylate, 2-4 parts of montmorillonite, 2-2.5 parts of modified kaolin, 1.5-2 parts of mica, 1.5-2 parts of quartz powder, 2-5 parts of auxiliaries and 2-5 parts of added master batch. The plastic woven bag has high tensile load and high breaking strength, and effectively inhibits damages which are generated in processing and storage processes.

Owner:桐城市华猫软膜有限公司

Diaphragm valve

ActiveUS9476510B2Easy to driveImprove life expectancyDiaphragm valvesOperating means/releasing devices for valvesDiaphragm valveDiaphragm seal

A diaphragm valve has a valve housing and a valve member movable relative to said housing. The valve member includes a diaphragm carrier that can be driven to execute a switchover motion having a sealing diaphragm mounted thereon, which delimits a valve chamber in which a valve seat is found. The sealing diaphragm has a sealing section opposite said valve seat belonging at least partially to a loose diaphragm section of the sealing diaphragm, which can lift from the diaphragm carrier to reduce the stress on the sealing diaphragm when said diaphragm carrier is removed from the valve seat during switching.

Owner:FESTO AG & CO KG

Connecting socket for filter hoses

InactiveUS9151423B2Stable and connection of and connectingLow production costSleeve/socket jointsFluid pressure sealed jointsEngineeringMechanical engineering

Owner:MANN HUMMEL GMBH

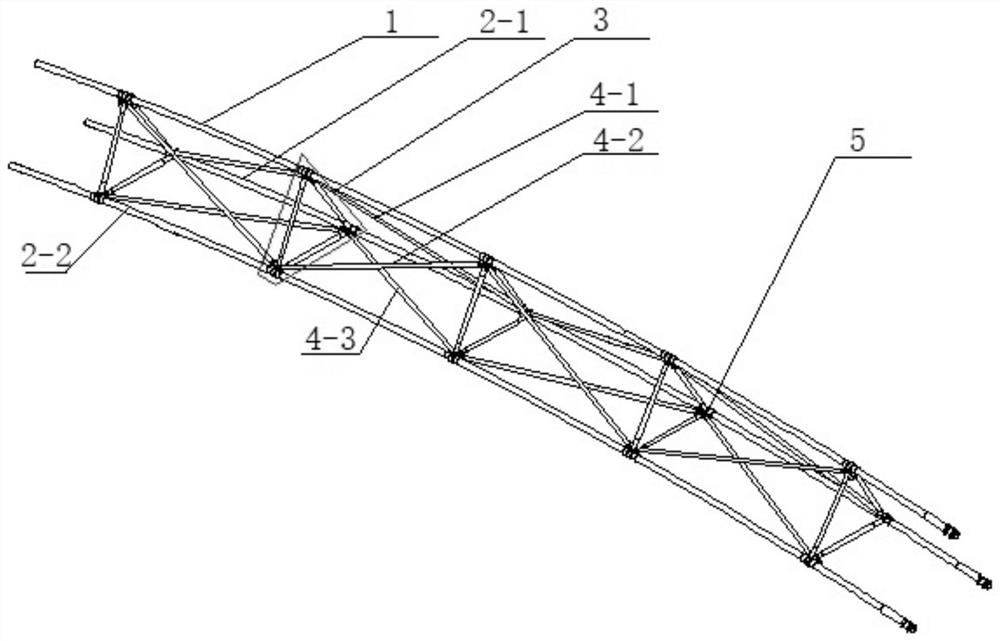

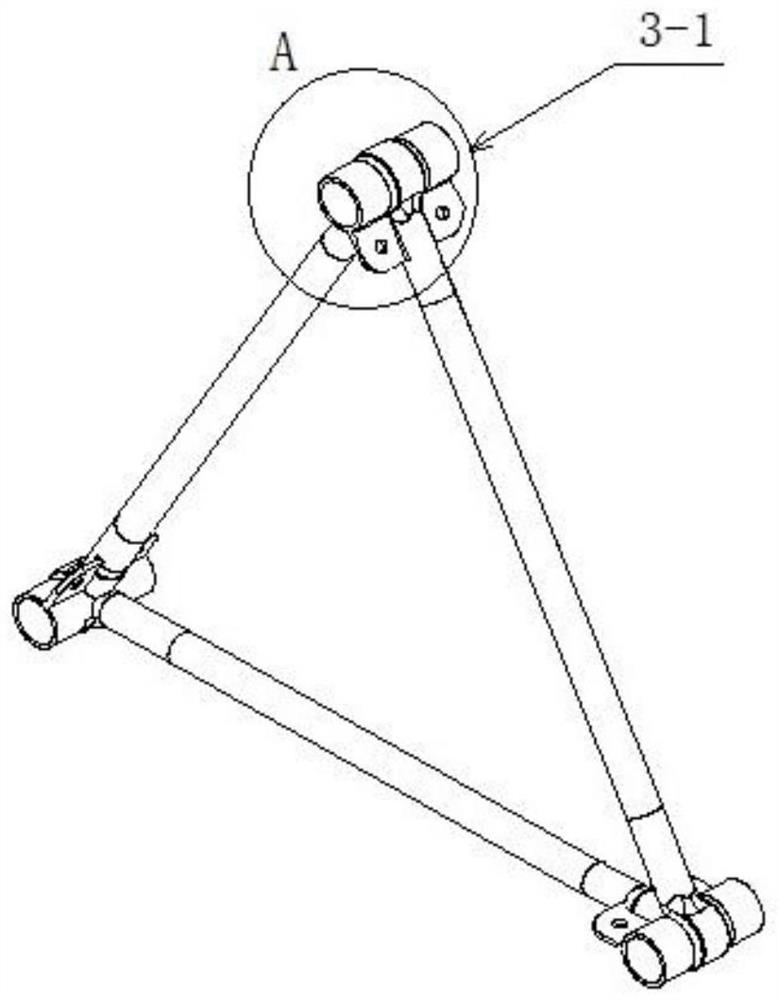

Triangular-section arc-shaped composite truss and preparation method thereof

ActiveCN112722232ALarge connection cross sectionImprove overall structural rigidityFuselage framesCosmonautic vehiclesCarbon fiber compositeDimensional precision

The invention discloses a triangular-section arc-shaped composite truss which is of an arc-shaped three-dimensional structure formed by connecting an outer chord member, a first inner chord member and a second inner chord member which are parallel to one another through a triangular-section web member assembly. A first outer diagonal web member, a second outer diagonal web member and an inner diagonal web member are diagonally arranged on the outer chord member, the first inner chord member and the second inner chord member between the adjacent triangular section web member assemblies respectively and are fixedly connected with the four-way joint, and each member is made of a carbon fiber composite material; the invention further discloses a preparation method of the triangular-section arc-shaped composite material truss. The large-radian composite material truss structure with the curvature is formed by connecting the web member assemblies with the triangular sections, the size precision is high, the loading performance is good, the truss structure achieves ultra-light weight, and modular connection of large composite material pipe trusses is achieved; the self-heating mold is adopted for preparation, curing equipment does not need to enter or exit, the quality stability of the arc rod piece is improved, and the size precision is high.

Owner:XIAN KANGBEN MATERIAL

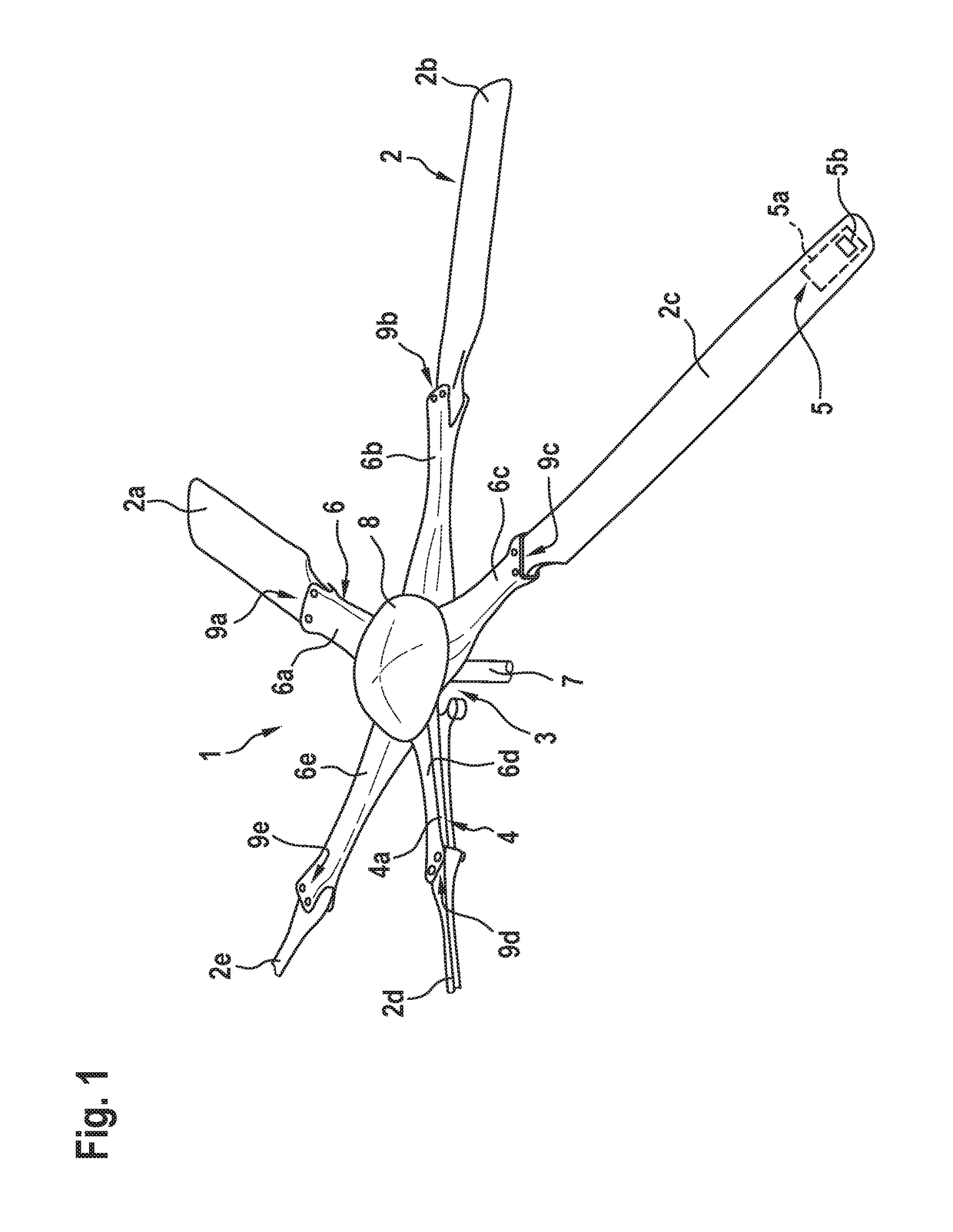

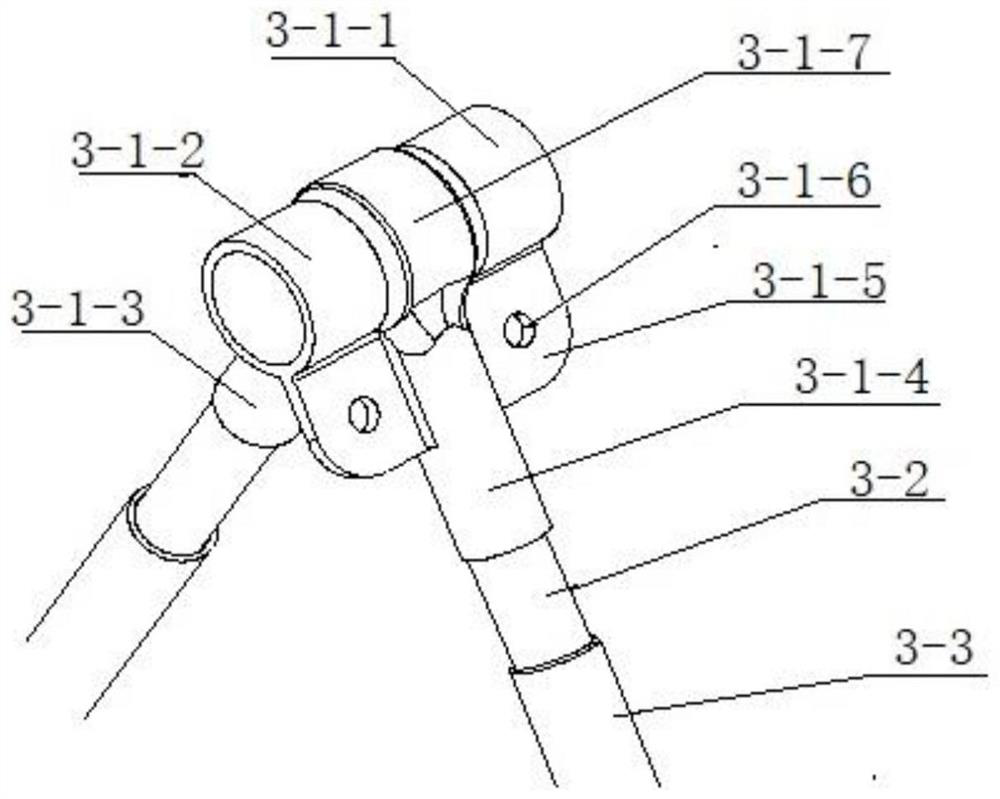

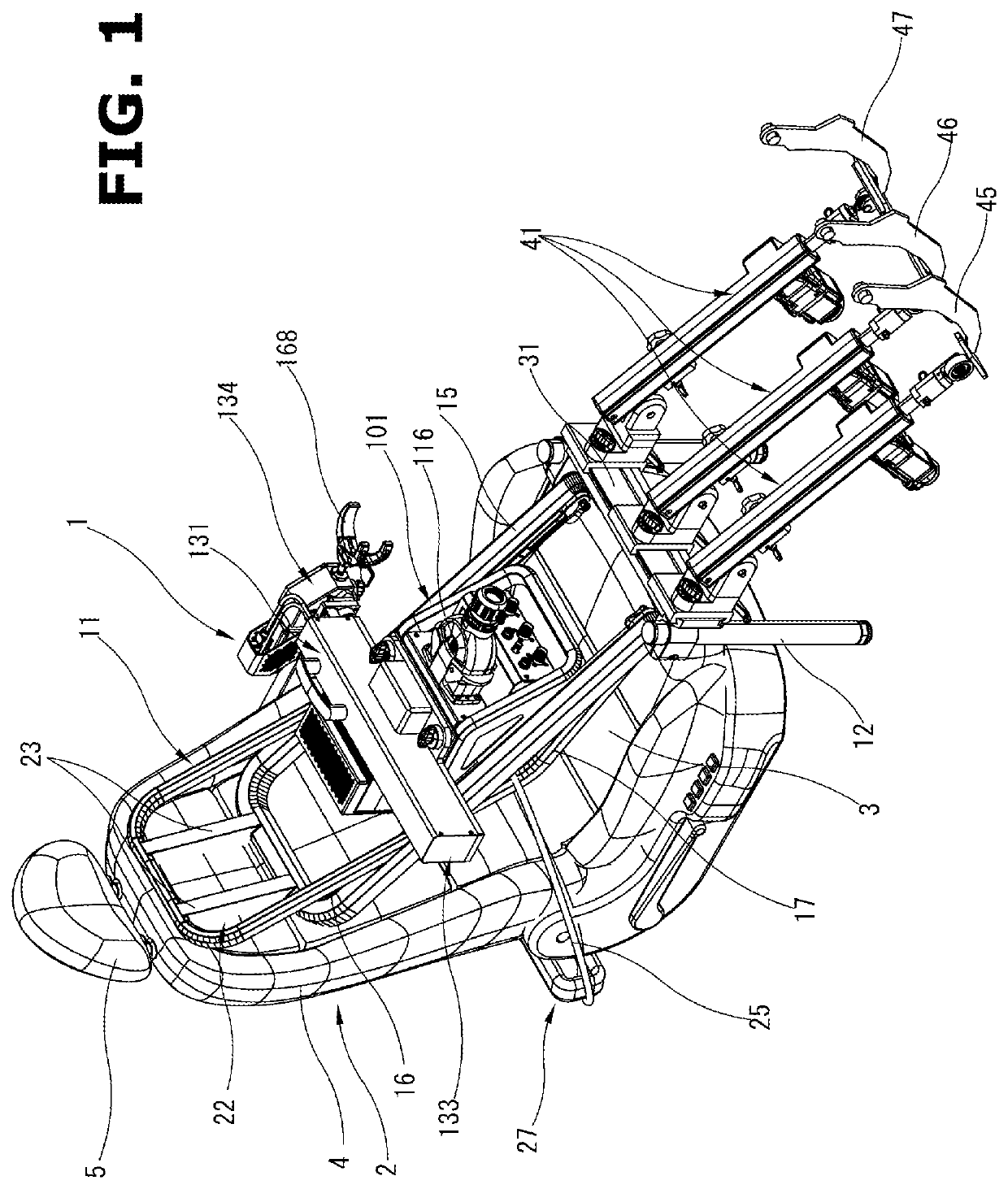

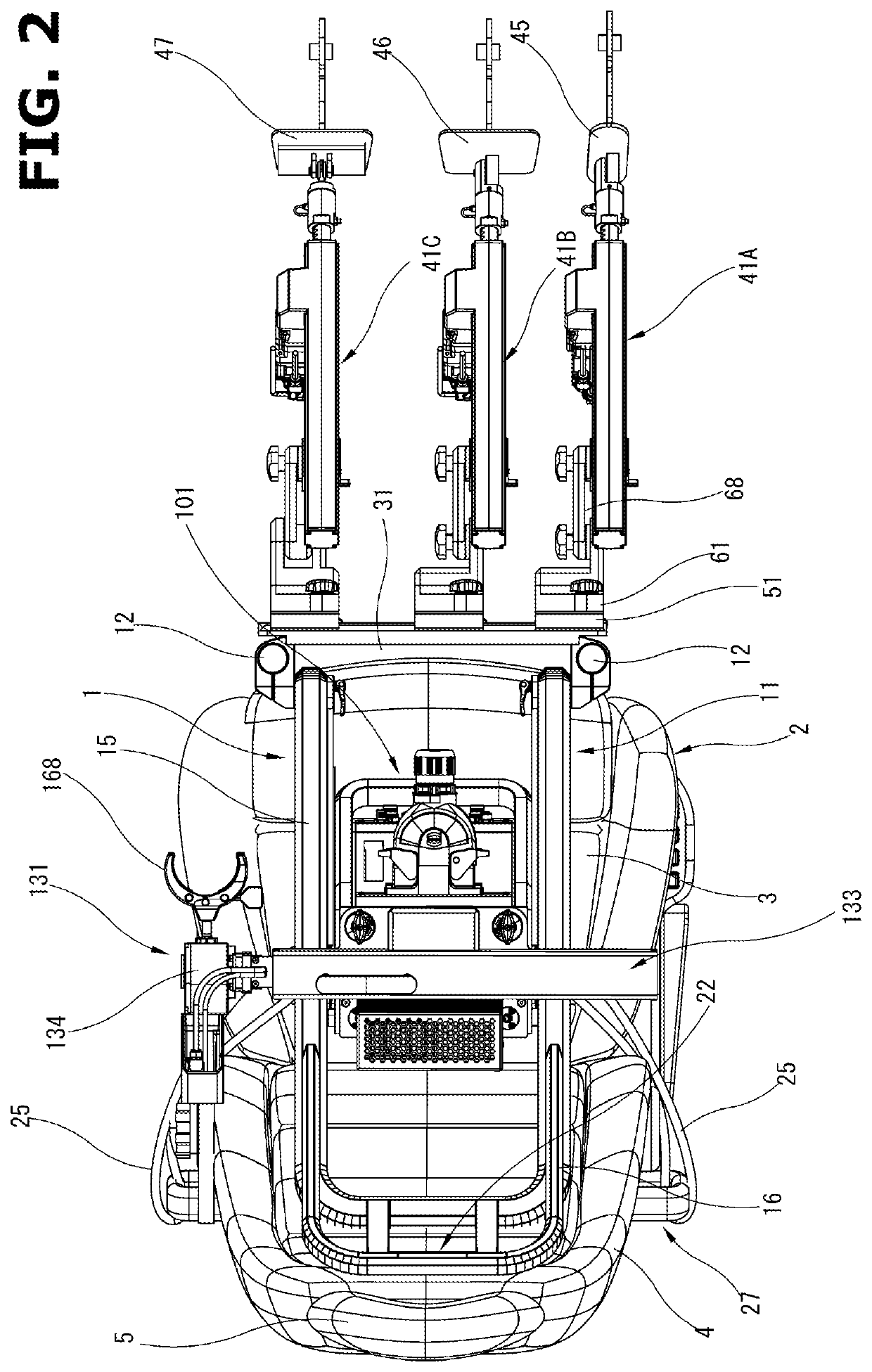

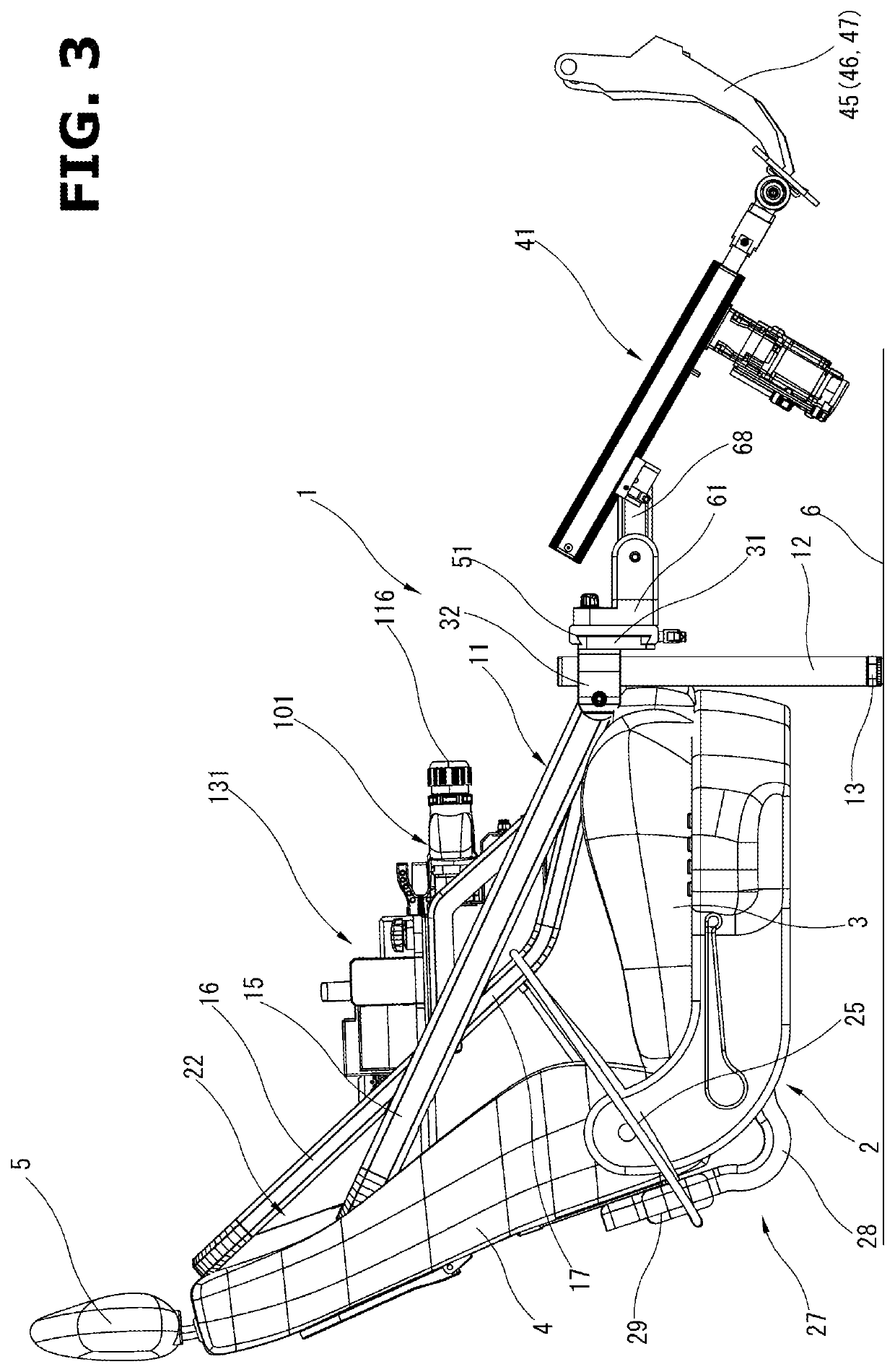

Support structure for automatic vehicle driving device

ActiveUS11453350B2Flexible structureLoad largeVehicle testingVehicle arrangementsVehicle drivingActuator

An automatic vehicle driving device (1) including a transmission actuator unit (131) and pedal actuators (41) is supported as a whole by a frame (11) and legs (12). The frame (11) extends obliquely downward from a seat back abutting part (22) located at an upper end of the frame (11) toward a vehicle front side. The frame (11) is provided with the pair of legs (12) at a top end of the frame (11). The legs (12) extend downward along a front end of a seat cushion (3) and abut against the vehicle body floor (6). By tightening a belt (25) between the frame (11) and a seat support (27), the frame (11) is pulled obliquely downward and is firmly fixed. Since a flexible seat cushion (3) does not bear a load of the device (1), vibrations of the device (1) during a running test do not easily occur.

Owner:MEIDENSHA ELECTRIC MFG CO LTD

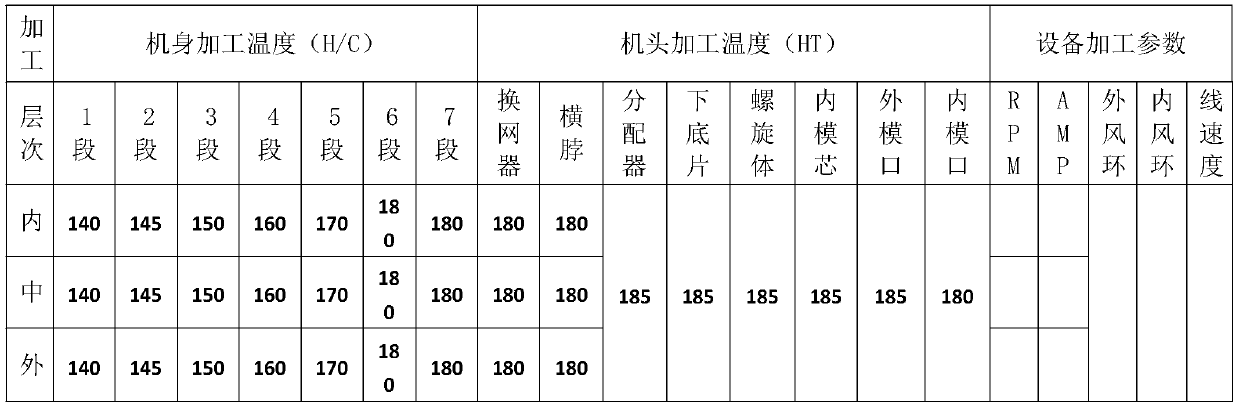

Environment-friendly, high-strength and weather-resistant yellow and black mulch film and preparation method

InactiveCN110741855AEasy to recycleGood tensile propertiesSynthetic resin layered productsFlat articlesWeather resistanceSoil science

The invention relates to the technical field of agricultural plastic products and aims to provide an environment-friendly, high-strength and weather-resistant yellow and black mulch film and a preparation method. The yellow and black mulch film is in a three-layer composite structure including an inner layer, a middle layer and an outer layer. The inner layer is mainly prepared from low-density polyethylene, linear low-density polyethylene, black masterbatch and long-lived masterbatch. The middle layer is mainly prepared from metallocene polyethylene, linear low-density polyethylene, yellow masterbatch and long-lived masterbatch. The outer layer is mainly prepared from low-density polyethylene, linear low-density polyethylene, yellow masterbatch and long-lived masterbatch. The yellow and black mulch film has advantages that the yellow and black mulch film is a high-technology environment-friendly agricultural mulch film product specially designed for green non-pollution vegetable, melon and fruit planting and field crops, and the product with metallocene as a main material has advantages of high strength and ultralong service life and has functions of weeding, insect prevention andthe like by adoption of advanced three-layer co-extrusion equipment.

Owner:甘肃济洋塑料有限公司

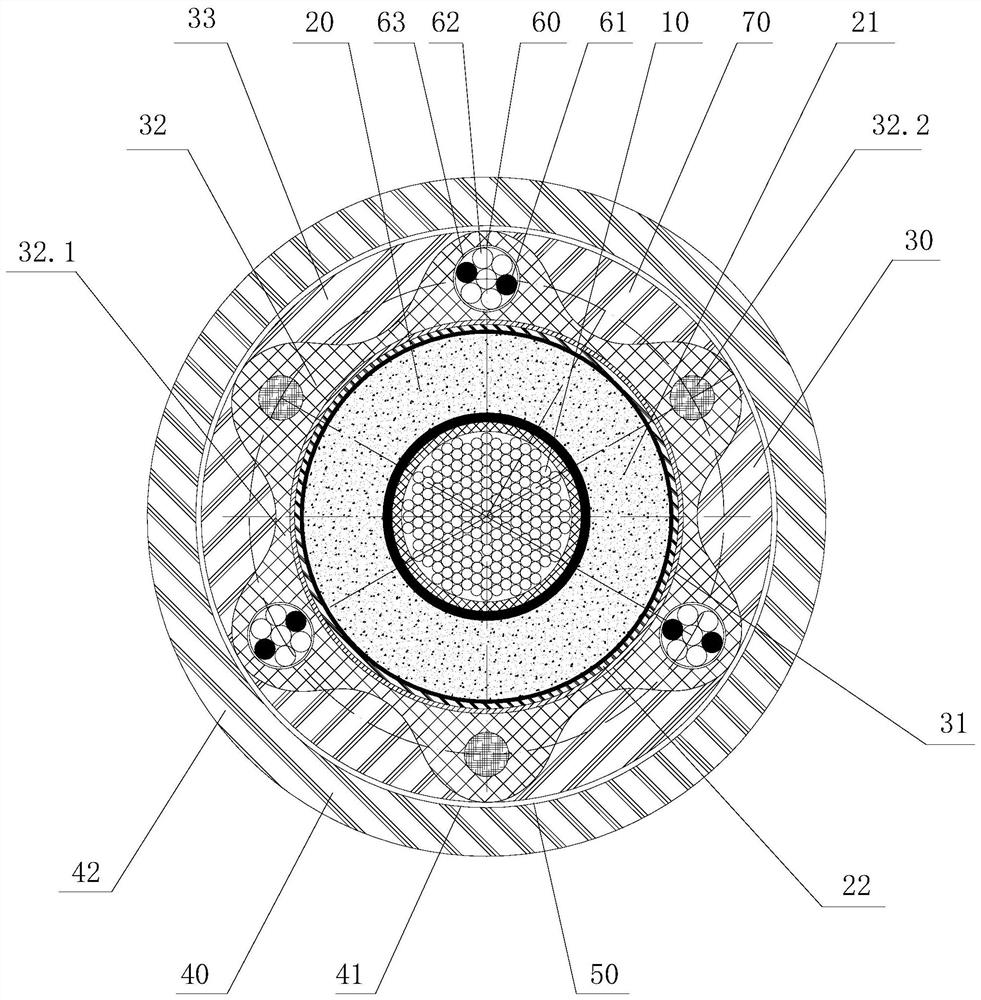

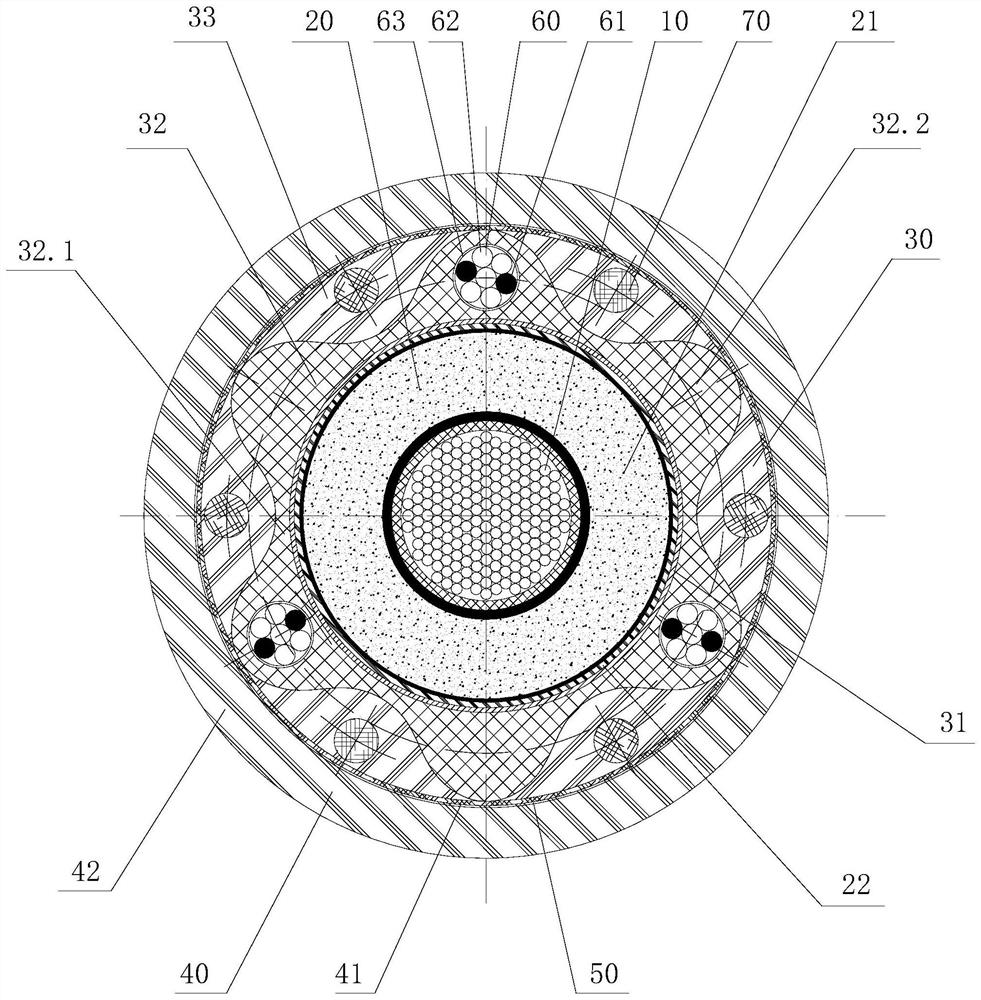

A high-voltage DC optical fiber power composite submarine cable

ActiveCN112509733BGood flexibilityIncrease the tensile loadSubmarine cablesPower cables including optical transmission elementsFiber bundleEngineering

Owner:FEIZHOU GRP

Manufacturing method of lightweight connecting rod with rubber-metal ball joint

A method for manufacturing a lightweight connecting rod with a rubber-metal ball joint, firstly making a rubber-metal ball joint and a reinforced body separately, then putting the rubber-metal ball joint into the reinforced body, and embedding the rubber-metal ball joint jacket into the reinforced body In the hole of the ball hinge, put the reinforced body embedded with the rubber-metal ball hinge into the molding mold, and wrap the lightweight polymer material on the outside of the rubber-metal ball hinge and the reinforcement body by injection molding and molding. Forms a lightweight linkage with rubber-to-metal ball joints. The invention puts the rubber-metal ball hinge into the reinforced body, and then composites lightweight polymer materials on the rubber-metal spherical hinge outer shell and the outside of the reinforced body to form a lightweight connecting rod composed of two materials, so that the product can be used in the main The load-bearing capacity in the load-bearing direction has been improved, increasing the load-bearing and application range of the thrust rod.

Owner:BOGE RUBBER&PLASTICS ZHUZHOU CO LTD

Modified fiber for wallpaper, and production method thereof

InactiveCN107904926AIncrease the tensile loadFibre treatmentInorganic compound additionFiberWater baths

The invention discloses a modified fiber for wallpaper, and a production method thereof. The production method comprises the following steps: 1, mixing sodium silicate with a dispersant in the presence of a solvent, and carrying out water bath heating at 35-45 DEG C to prepare a mixture M1; 2, dropwise adding an aqueous solution of ammonium chloride to the mixture M1 prepared in step 1 under a 35-45 DEG C water bath heating condition, abandoning the obtained supernatant, and taking the obtained precipitate; 3, drying the precipitate, and calcining the dried precipitate to prepare granules; and4, adding the granules prepared in step 3 and a coupling agent to a water slurry containing fibers, and stirring and mixing all above materials at 60-80 DEG C for 1-3 h to produce the modified fiberfor wallpaper. The modified fiber produced through the above materials and the method can effectively improve the tension load of wallpaper made of waste paper pulp.

Owner:ANHUI YINTU DECORATION MATERIALS CO LTD

Diaphragm valve

ActiveCN104302957BExtend your lifeIncrease the tensile loadDiaphragm valvesOperating means/releasing devices for valvesDiaphragm valveValve seat

A diaphragm valve (1) is proposed having a valve housing (2) and a valve part (3) movable relative to the valve housing. The valve part (3) comprises a diaphragm carrier (6) which can be driven to perform a switching movement (26), which carries a sealing diaphragm (8) fixed there, which delimits the valve chamber (7), the valve seat (47) is located in the valve cavity (7). The sealing diaphragm (8) has a sealing section (53) lying opposite the valve seat (47), which at least partially belongs to the loose diaphragm section (55) of the sealing diaphragm (8), when the diaphragm carrier is in the When removed from the valve seat (47) in the case of switching, the loose diaphragm section (55) can be lifted from the diaphragm carrier (6) in order to reduce the stress on the sealing diaphragm (8).

Owner:FESTO AG & CO KG

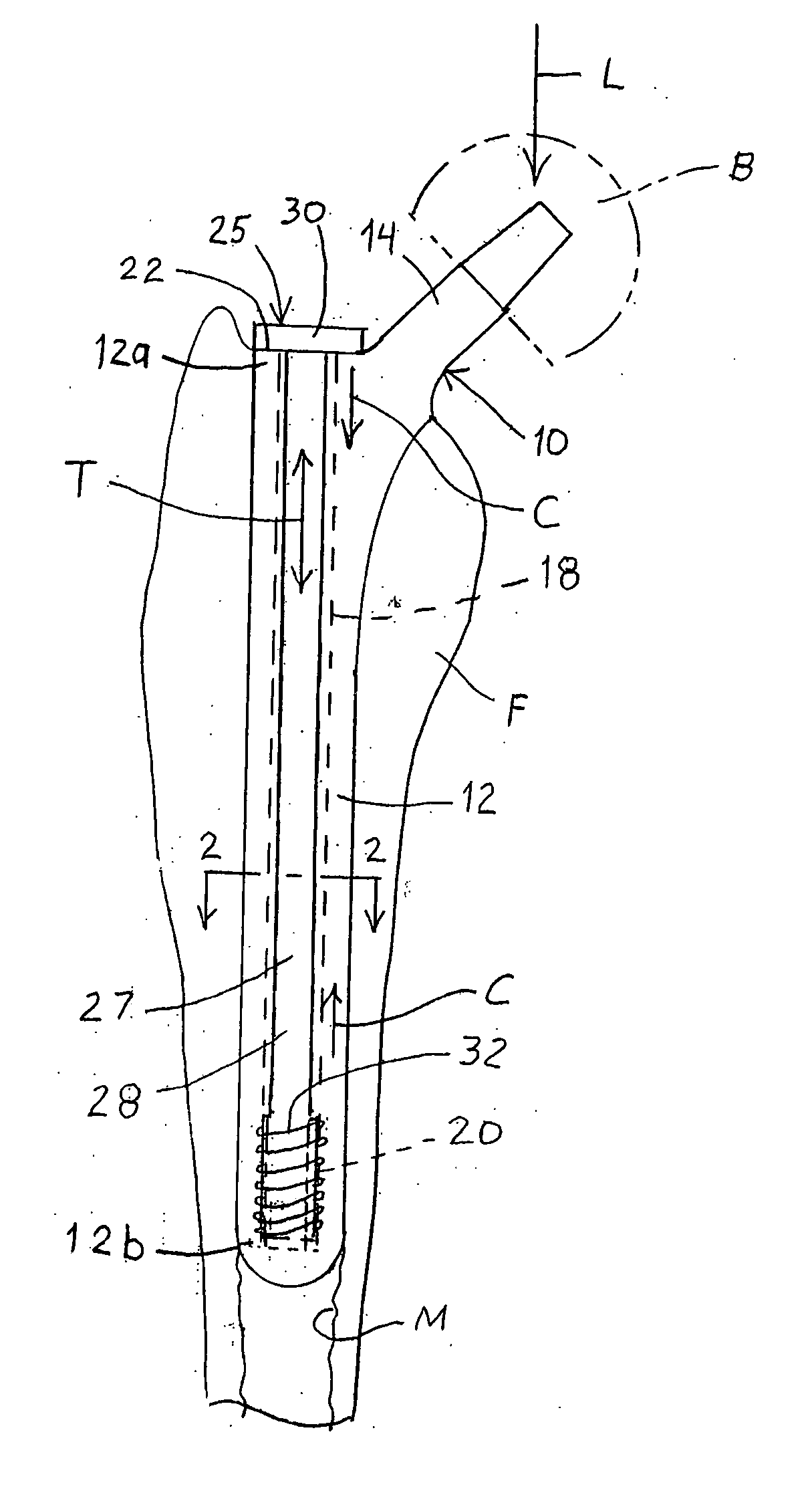

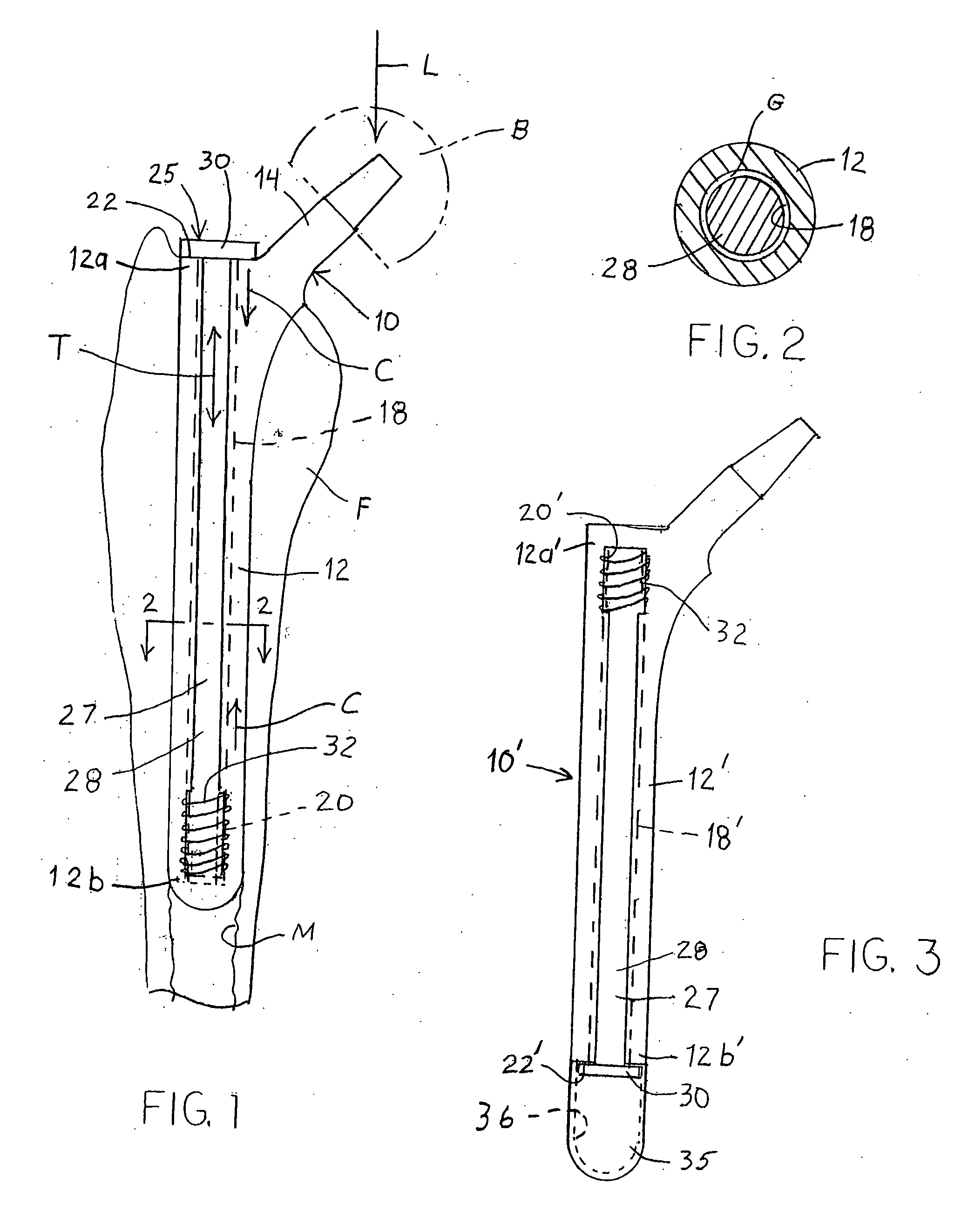

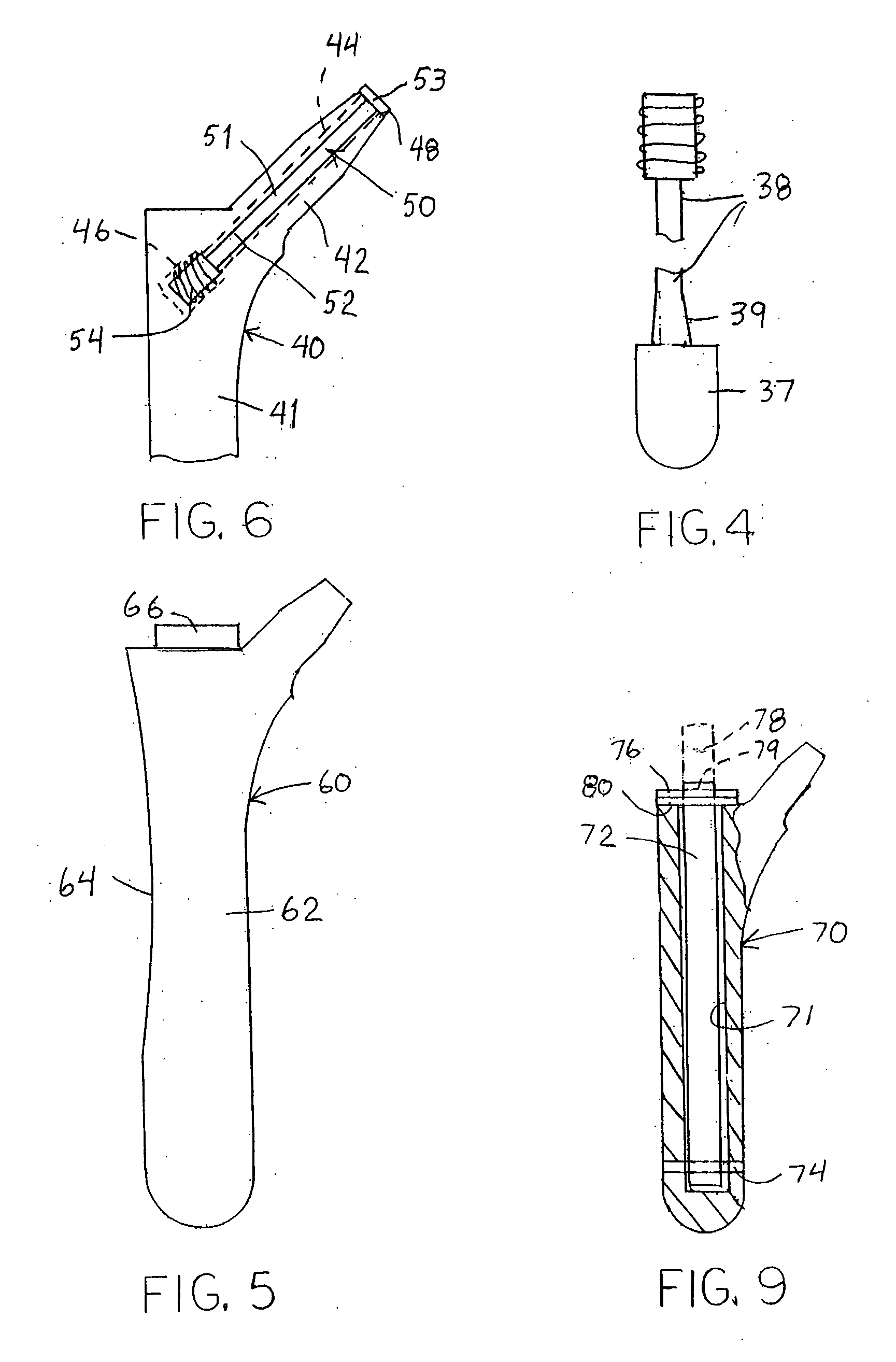

Pre-stressed implant

InactiveUS20060259152A1Readily withstand compressive loadStrong and durable implantBone implantJoint implantsPre stressPre stressing

A pre-stressed orthopaedic implant includes a tension member extending through a bore in the implant. The tension member can include a bolt that is tightened into threads at the closed end of the bore, thereby compressing the implant between the bolt head and the threaded engagement. The implant is fixed within a bone while the implant is maintained in compression to improve the implant's ability to withstand tensile loads.

Owner:DEPUY PROD INC

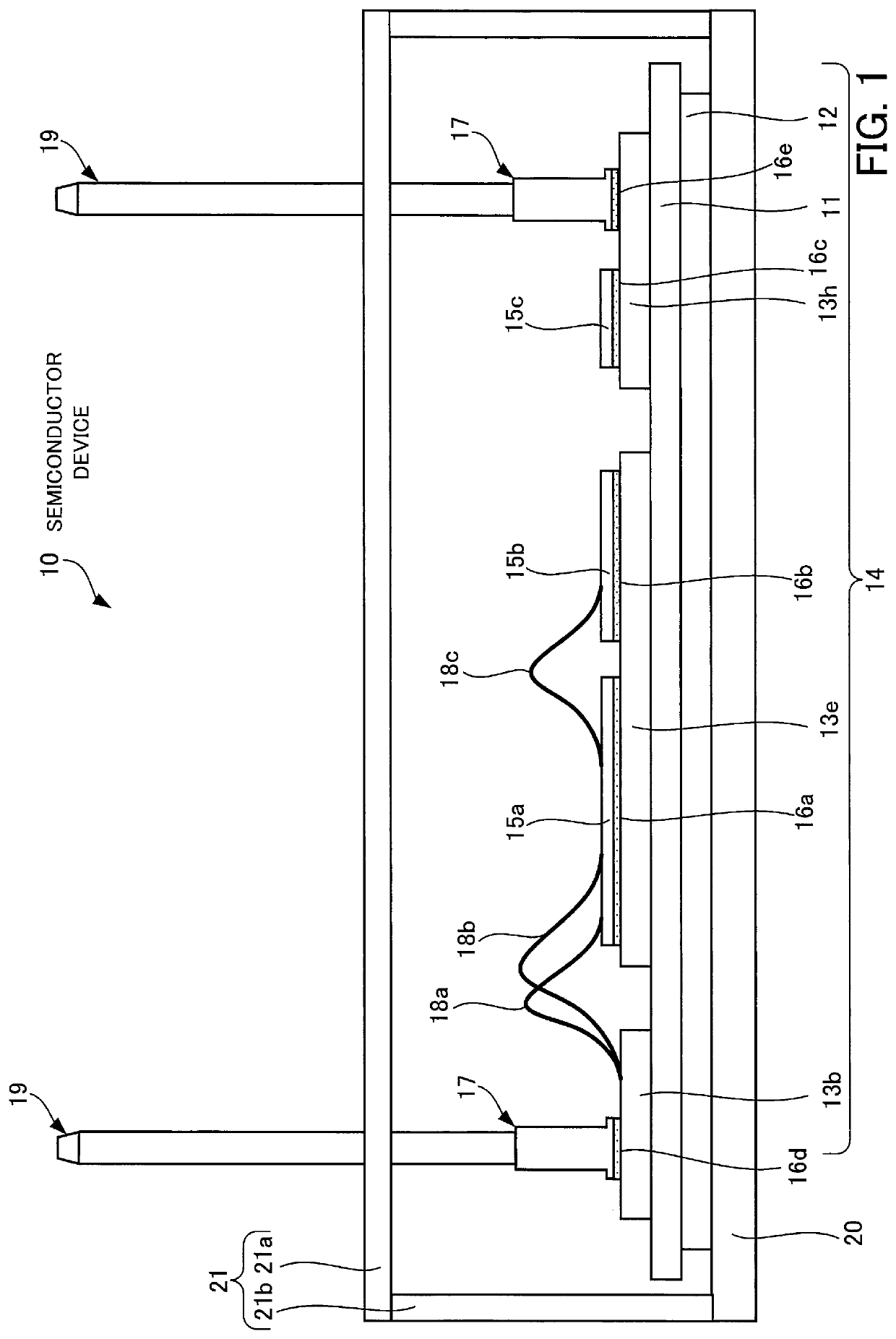

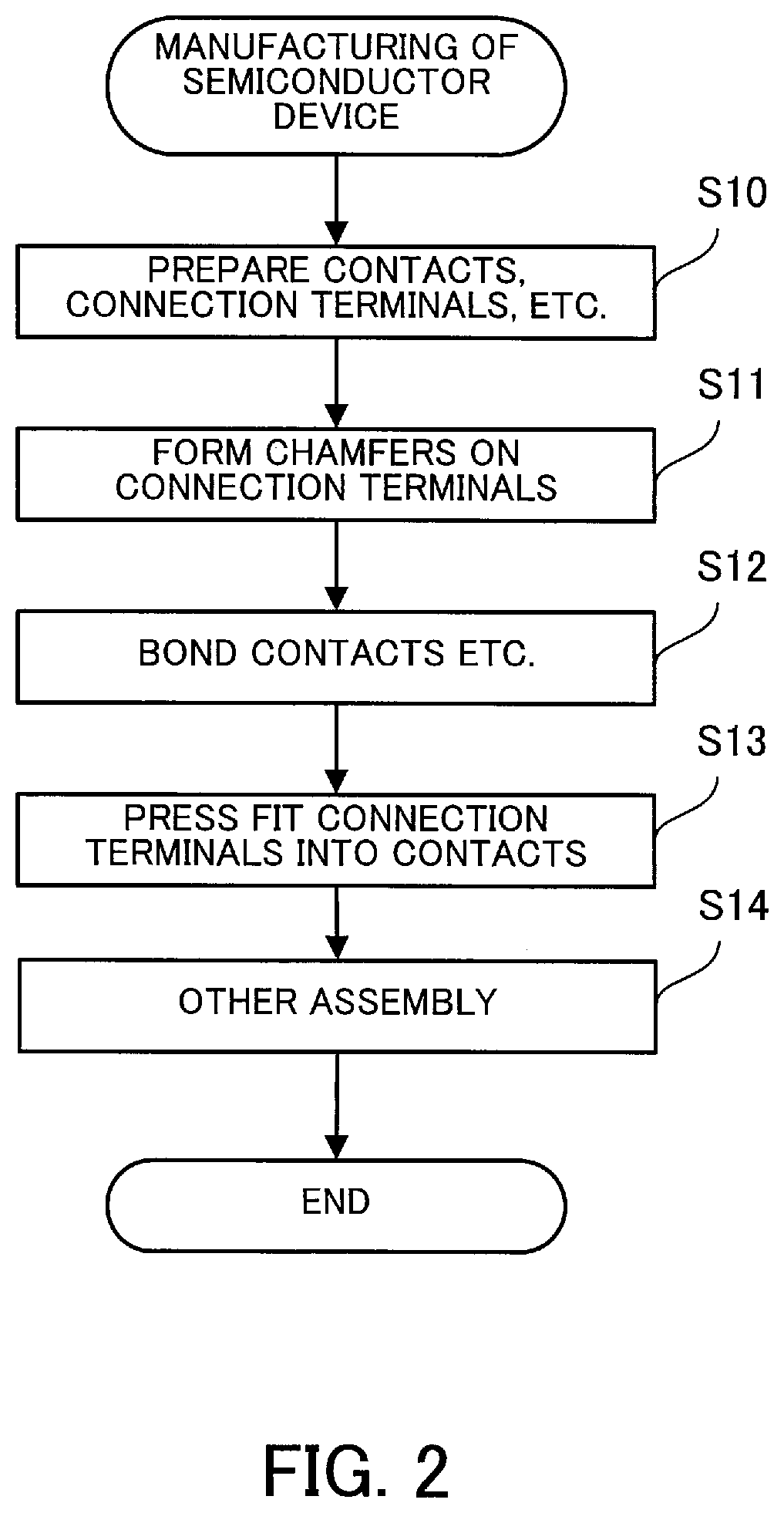

Semiconductor device manufacturing method and semiconductor device

ActiveUS11295997B2Increase the tensile loadRestrain the decline in reliabilityFinal product manufactureSemiconductor/solid-state device detailsDevice materialEngineering

Owner:FUJI ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com