A kind of high tensile load composite material pipe fitting and its preparation method

A composite material and composite material layer technology, applied in the field of composite material forming, can solve problems such as the inability to meet high tensile load bearing requirements, achieve the effect of weakening the tendency of early failure, increase tensile load, and solve local bridging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

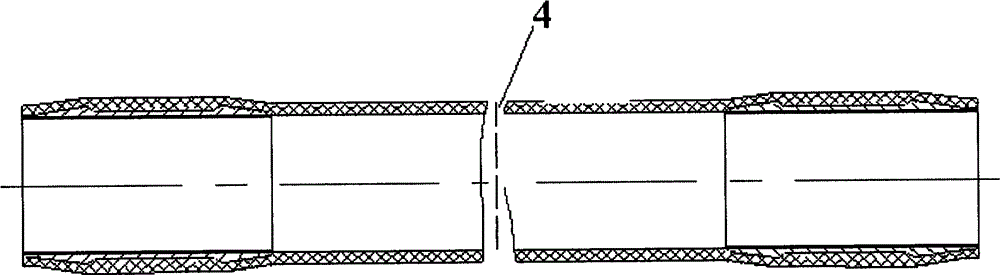

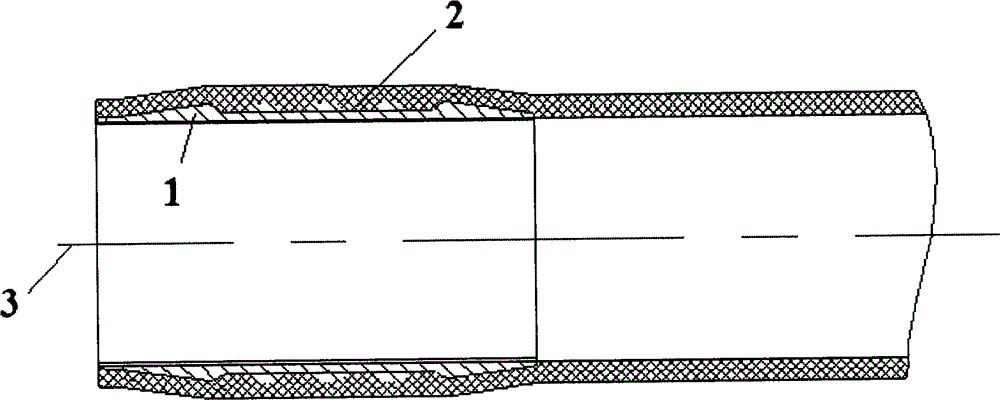

[0023] Such as figure 1 with figure 2 As shown, a high tensile load composite material pipe fitting, the pipe fitting includes an embedded part 1 and a composite material layer 2; the composite material layer 2 is coated on the periphery of the embedded part 1,

[0024] There is one embedded part 1 at each end of the pipe fitting; each embedded part 1 is symmetrical up and down with respect to the center line 3 of the pipe fitting, and the two embedded parts 1 are left-right symmetrical about the central axis 4 of the pipe fitting;

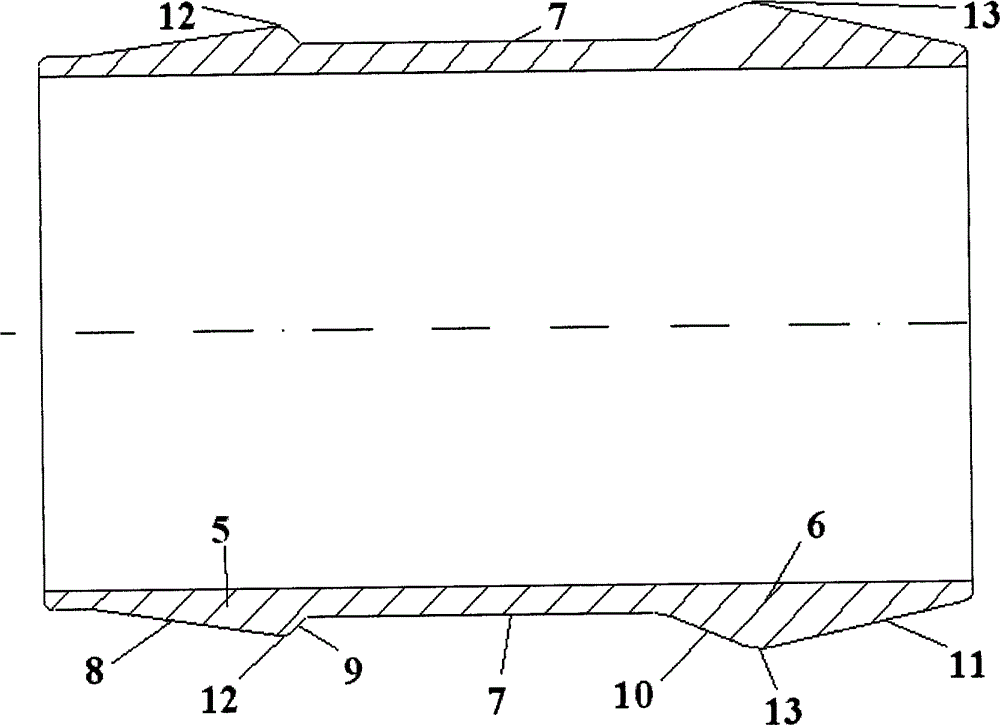

[0025] Such as image 3 with Figure 4 As shown, the embedded part 1 has a hollow cone angle structure, and there are two cone angle structures of the embedded part 1, which are the cone angle A5 and the cone angle B6; the area formed between the cone angle A5 and the cone angle B6 is a groove 7;

[0026] The cone angle A5 is composed of one ascending line A8 and one descending line A9, the angle between the ascending line A8 and the center l...

Embodiment 2

[0038] Same as Example 1, the difference is that the taper angles of the embedded parts are 4, such as Image 6 with Figure 7 shown.

[0039] The implementation plan takes key technologies such as metal joint structure optimization and winding forming process optimization as the core, and carries out technological research one by one to complete the development of light-weight and heavy-duty composite material pipes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com