Diaphragm valve

A diaphragm valve, diaphragm technology, applied in the direction of diaphragm valve, diaphragm, valve details, etc., can solve problems affecting life, high stress, etc., and achieve the effect of high sealing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

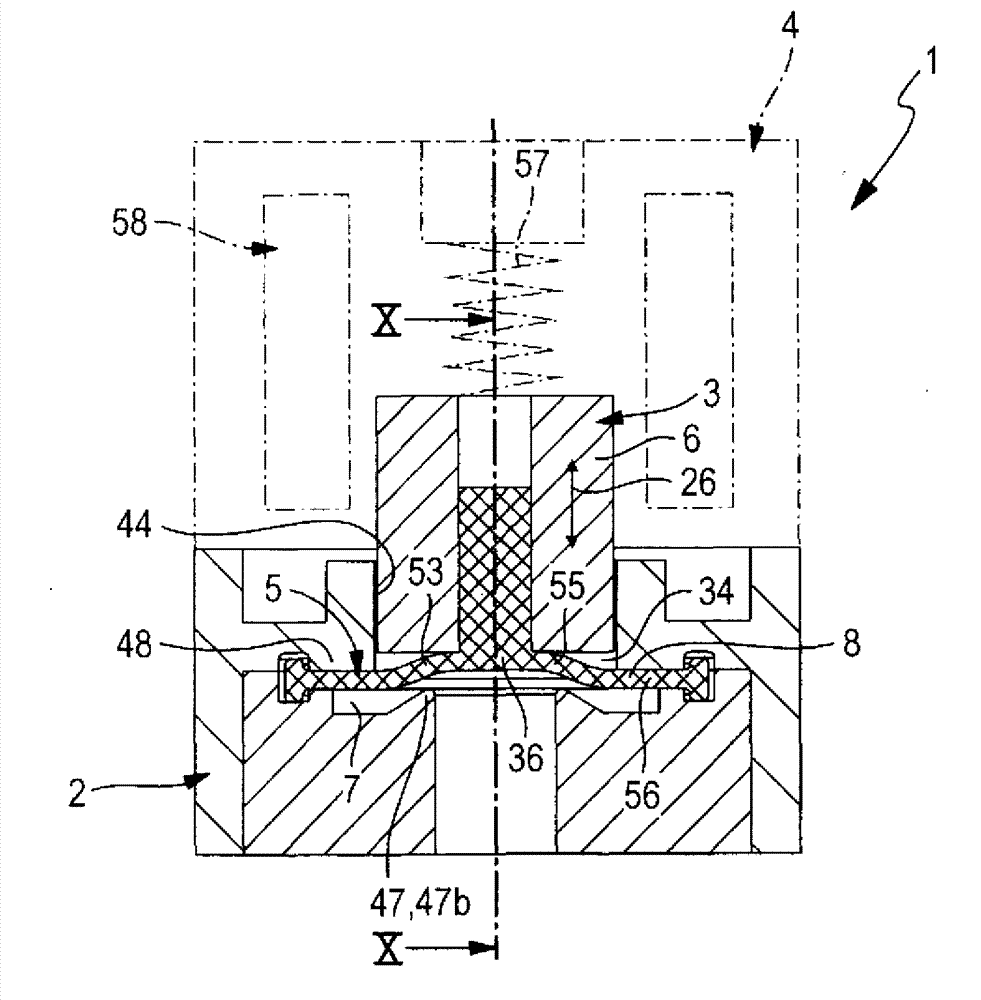

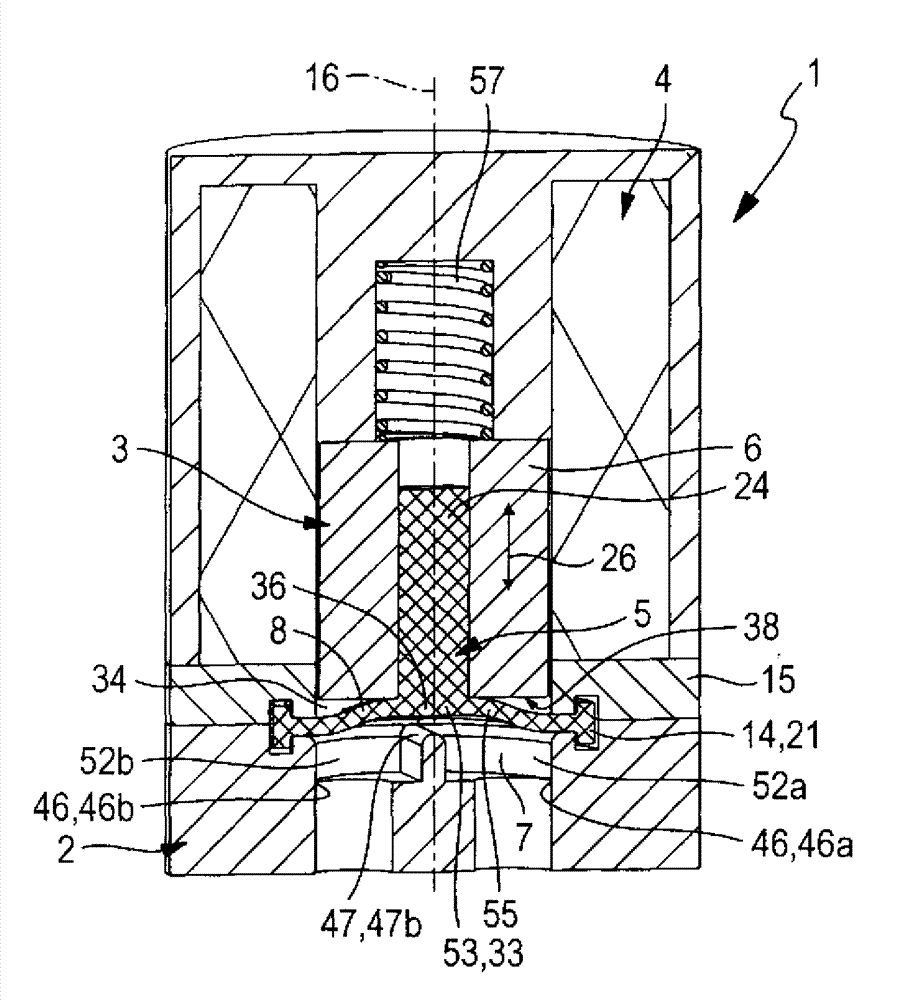

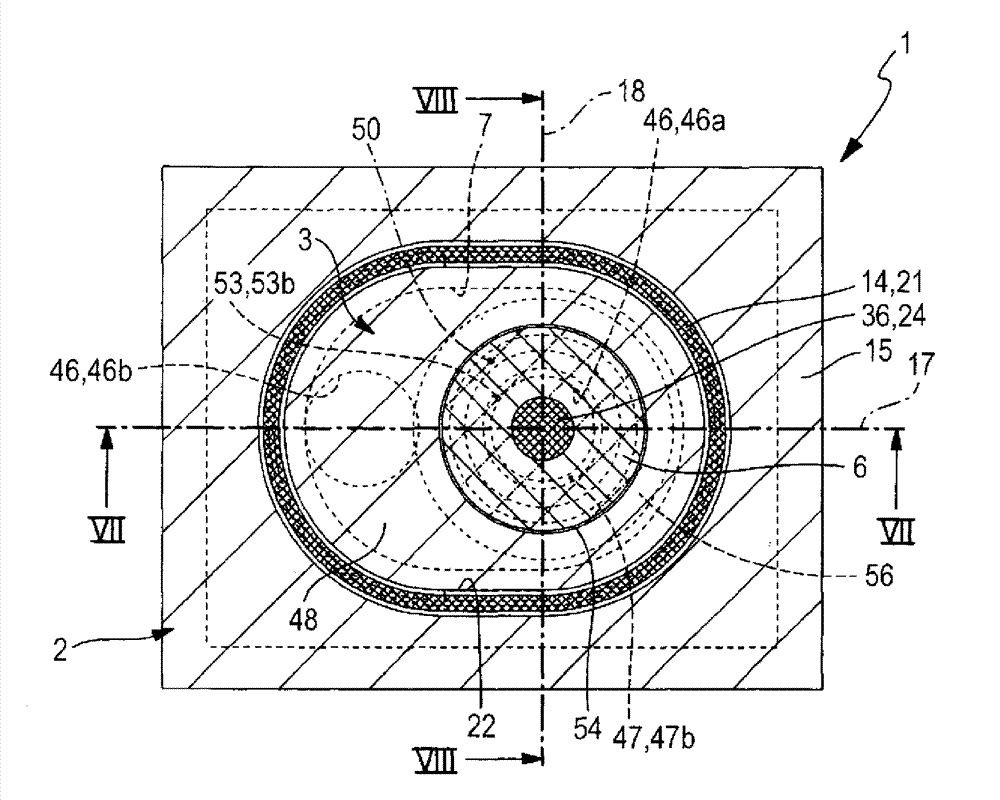

[0038] In all exemplary embodiments, the diaphragm valve, which is designated as a whole by the reference numeral 1 , has a valve housing 2 and a valve part 3 arranged in the valve housing 2 that is movable relative to the valve housing 2 . Furthermore, the diaphragm valve 1 is equipped with an electrically actuatable drive means 4 , preferably arranged in the interior of the valve housing 2 , by means of which the valve part 3 can be switched between two possible switching positions. figure 1 and 2 And 7 and 8 correspondingly show the first switching position, which is the closed position. Figures 4 to 6 And 10 and 11 correspondingly show the second switching position, which is for example the open position.

[0039] The valve part 3 is preferably designed as a composite element consisting of a membrane body 5 and at least one membrane carrier 6 carrying the membrane body 5 . These components are fixed to one another in a manner that will be explained further. Whereas the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com