A kind of production process of high modulus non-alkali glass fiber

An alkali-free glass fiber and production process technology, which is applied in the production process field of high-modulus alkali-free glass fiber, can solve the problems of low elastic modulus, easy oxidative discoloration, affecting tensile force, etc., and achieves high elastic modulus and improved tensile strength. Tensile load, the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

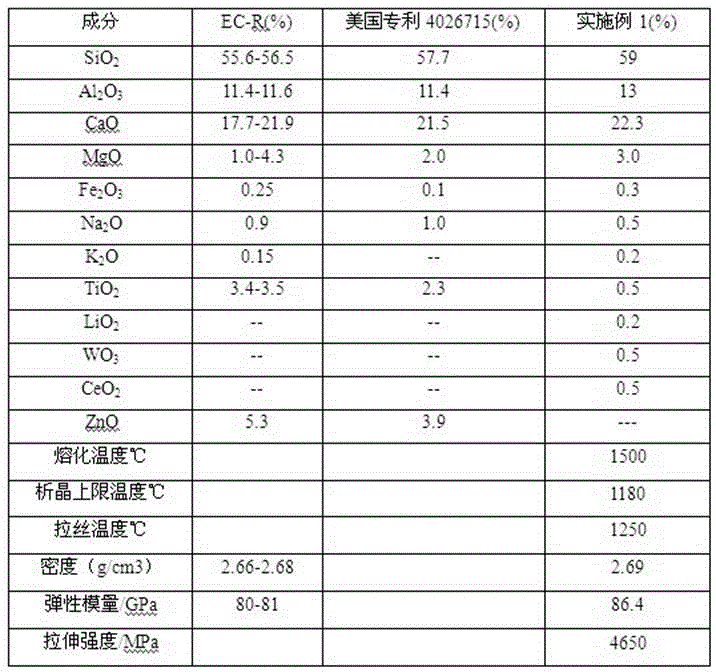

Embodiment 1

[0015] The composition and weight ratio of high modulus alkali-free glass fiber are: SiO 2 : 59%; TiO 2 : 0.5%; Al 2 o 3 : 13%; Fe 2 o 3 : 0.3%; CaO: 22.3%; LiO 2 : 0.2%; MgO: 3%; WO 3 : 0.5%; CeO 2 : 0.5%; Na 2 O: 0.5%; K 2 O: 0.2%.

[0016] The high-modulus alkali-free glass fiber of the above-mentioned components is prepared by the following process, specifically as follows:

[0017] Preparation of raw materials: Take 100g of quartz sand, 650g of pyrophyllite, 340g of limestone, 130g of dolomite, 5.2g of lithium carbonate, and 5.2g of cerium oxide, mix the above raw materials evenly, and the uniformity is ≥95%. The formula is consistent with the above ingredients and content . Although the composition of the raw materials is complex, the main components and impurity content of the raw materials used are regulated accordingly, and the glass with the above components can be prepared through the above material list.

[0018] Melting: Put the prepared raw materials ...

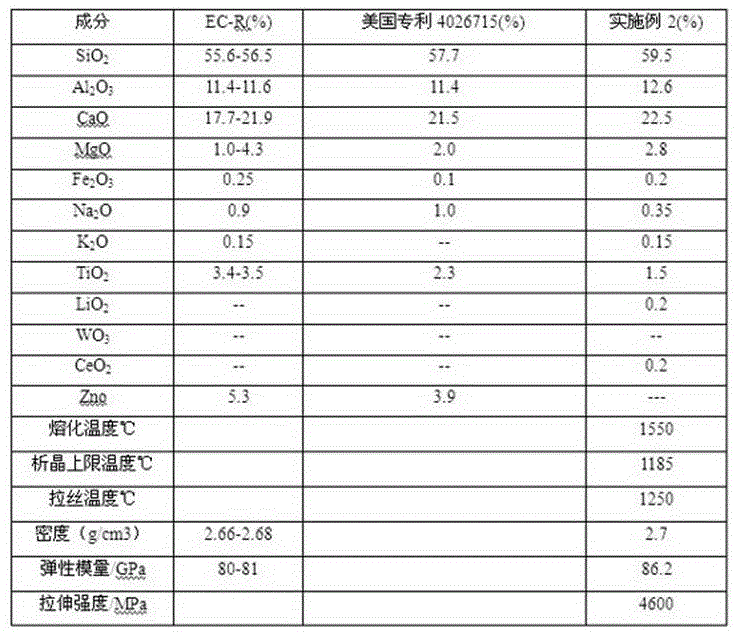

Embodiment 2

[0028] Process is identical with embodiment 1, and component and weight percentage thereof are: SiO 2 : 59.5%; TiO 2 : 1.5%; Al 2 o 3 : 12.6%; Fe 2 o 3 : 0.2%; CaO: 22.5%; LiO 2 : 0.2%; MgO: 2.8%; CeO 2 : 0.2%; Na 2 O: 0.35%; K 2 O: 0.15%. The corresponding material formula is as follows: dolomite: 13.0g; limestone: 35.0g; pyrophyllite: 63.0g; quartz sand: 12.0g; titanium oxide: 1.5g; lithium carbonate: 0.52g; cerium oxide: 0.2g.

[0029] The components and parts by weight of the dipping glue used in the dipping process are: 10 parts of 618 epoxy resin, 1 part of triethylenetetramine curing agent and 3 parts of acetone diluent.

[0030] Embodiment 2 compares with the test result of prior art:

[0031] The product was tested in a pilot test, and the data results after the pilot test were compared with EC-R glass and US Patent No. 4026715. The data are as follows:

[0032]

[0033] WO is not used in this example 3 , the purpose is to reduce the cost as much as pos...

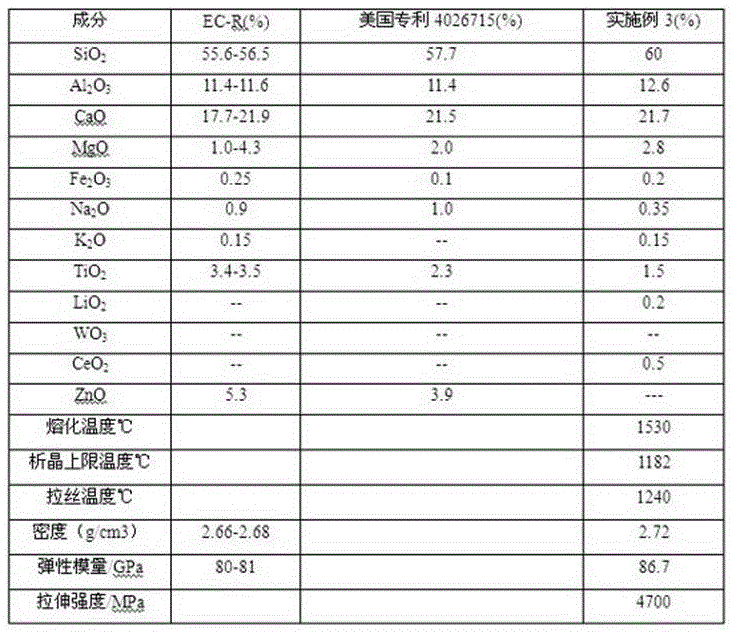

Embodiment 3

[0035] Process is identical with embodiment 1, and component and weight percentage thereof are: SiO 2 : 60%; TiO 2 : 1.5%; Al 2 o 3 : 12.6%; Fe 2 o 3 : 0.2%; CaO: 21.7%; LiO 2 : 0.2%; MgO: 2.8%; CeO 2 : 0.5%; Na 2 O: 0.35%; K 2O: 0.15%. The corresponding material formula is as follows: dolomite: 12.6g; limestone: 32.0g; pyrophyllite: 64.5g; quartz sand: 12.0g; titanium oxide: 1.3g; lithium carbonate: 0.5g; cerium oxide: 0.52g.

[0036] The components and parts by weight of the dipping glue used in the dipping process are: 10 parts of 618 epoxy resin, 1 part of triethylenetetramine curing agent and 4 parts of acetone diluent.

[0037] Embodiment 3 is compared with the test result of prior art:

[0038] The product was tested in a pilot test, and the data results after the pilot test were compared with EC-R glass and a US patent number: 4026715. The data are as follows:

[0039]

[0040] The reproducibility test of the experimental results was carried out on the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com