Upper connecting plate forming stamping die

A stamping die and connecting plate technology, applied in the field of mechanical processing, can solve problems such as low production capacity, low work efficiency, and lower punching accuracy of the upper connecting plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

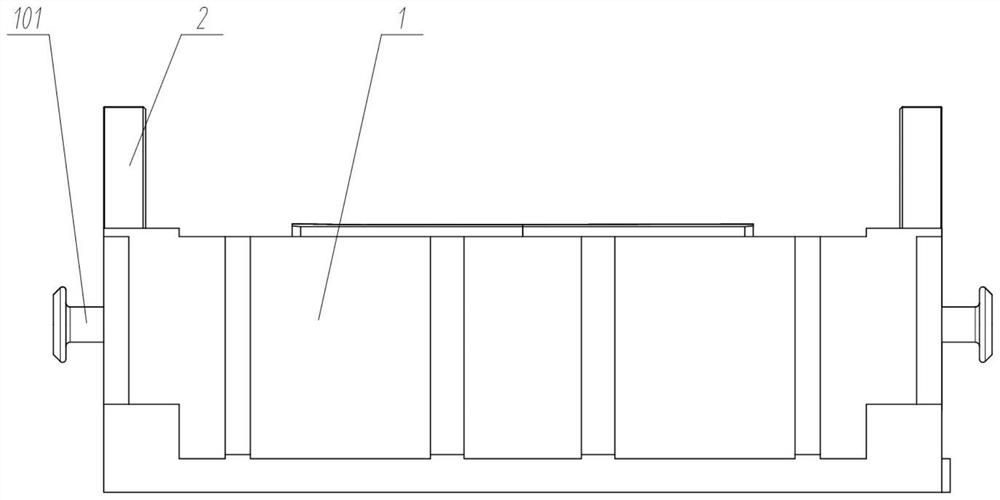

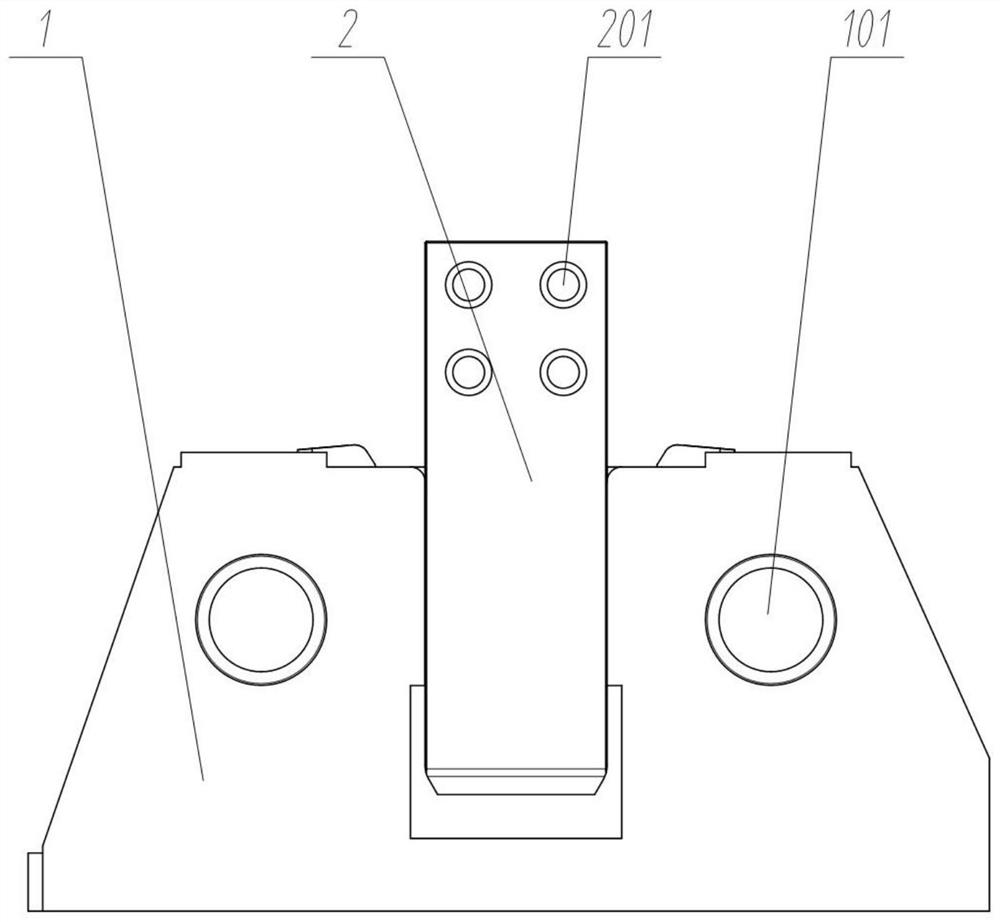

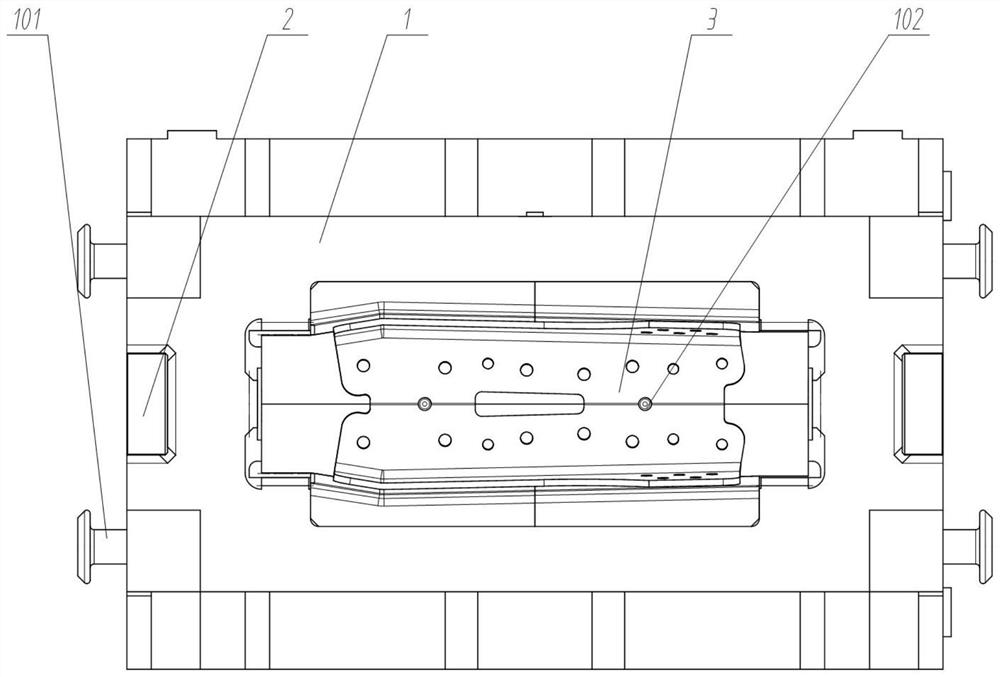

[0024] as attached figure 1 To attach Figure 4 Shown:

[0025] The invention provides a stamping die for forming an upper connecting plate, which includes a mold shell 1; a set of connecting blocks 2 are fixedly connected to the left and right sides of the mold shell 1; plate 3.

[0026] Wherein, the mold shell 1 has a trapezoidal structure, and when the mold shell 1 is placed, the trapezoidal structure makes the mold shell 1 more firm when placed.

[0027] Wherein, the mold shell 1 also includes cylindrical bumps 101, and two groups of cylindrical bumps 101 are fixedly connected to the left and right sides of the mold shell 1. In use, when the mold shell 1 needs to be moved, through The suspension rope is connected with the cylindrical bump 101 to realize the movement of the mold shell 1 .

[0028] Wherein, the mold shell 1 also includes a connecting plate installation positioning block 102, two sets of connecting plate installation positioning blocks 102 are fixedly con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap