Joint cutting mechanism for small veneers

A cutting mechanism and veneer technology, applied in the direction of making finger joints, etc., can solve the problem of lack of cutting devices, etc., and achieve the effect of improving efficiency and quickly cutting veneer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

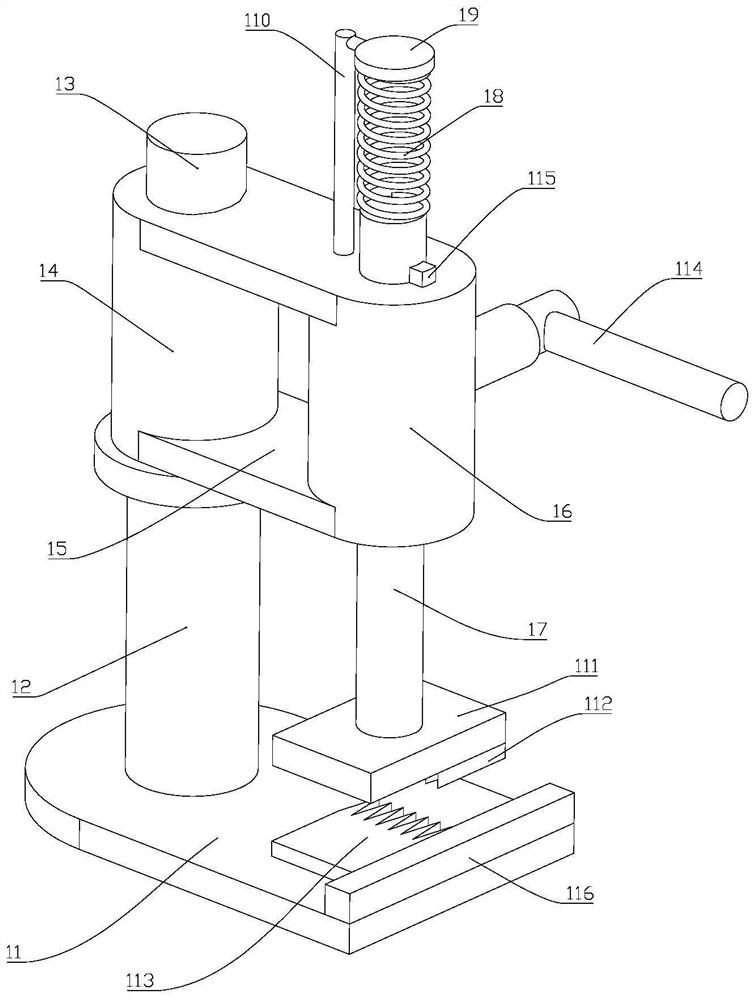

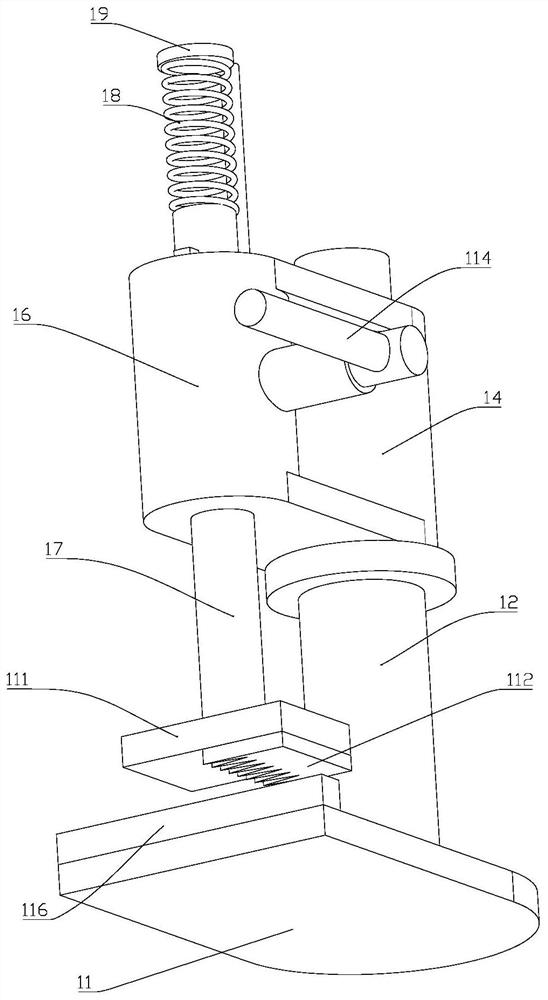

[0015] Such as figure 1 , 2 As shown, a small veneer joint cutting mechanism includes a cutting base 11, and a first support base 12 fixed on the cutting base 11, the top of the first support base 12 is fixed with a first rotating shaft 13, the The first rotating shaft 13 is matched with the first rotating sleeve 14, the first rotating sleeve 14 is fixedly connected with the first sliding sleeve 16 through the first connecting rod 15, and the first rotating sleeve 14 is connected with the first sliding sleeve. The axial directions of the sleeves 16 are parallel to each other. The first sliding sleeve 16 is matched with a first sliding shaft 17 which is relatively slidingly connected with the first sliding sleeve 16 . The top end of the first sliding shaft 17 passes through a first spring 18 Fixedly connected with the first fixing plate 19, the first fixing plate 19 is fixed above the first sliding sleeve 16 through the first support rod 110, the bottom end of the first slidin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap