Irregular metal whole plate splicing installation construction process

A construction technology and metal plate technology, which is applied in covering/lining, building, building structure, etc., can solve the problems of flatness, joint degree difficult to meet installation requirements, small adjustability, high installation cost, etc., to improve the overall vision effect, reduce installation cost, and save installation materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the splicing and installation construction process of the irregular metal whole plate described in the present invention, the installation process of the first embodiment of the molding column and the second embodiment of the modeling wall using the construction technology of the present invention will be described below in combination with the accompanying drawings. The construction steps are described in detail, and the terminology used in this specification is only used for the purpose of describing a specific version or embodiment, not for limiting the scope. In the drawings, the same reference numerals refer to the same parts throughout.

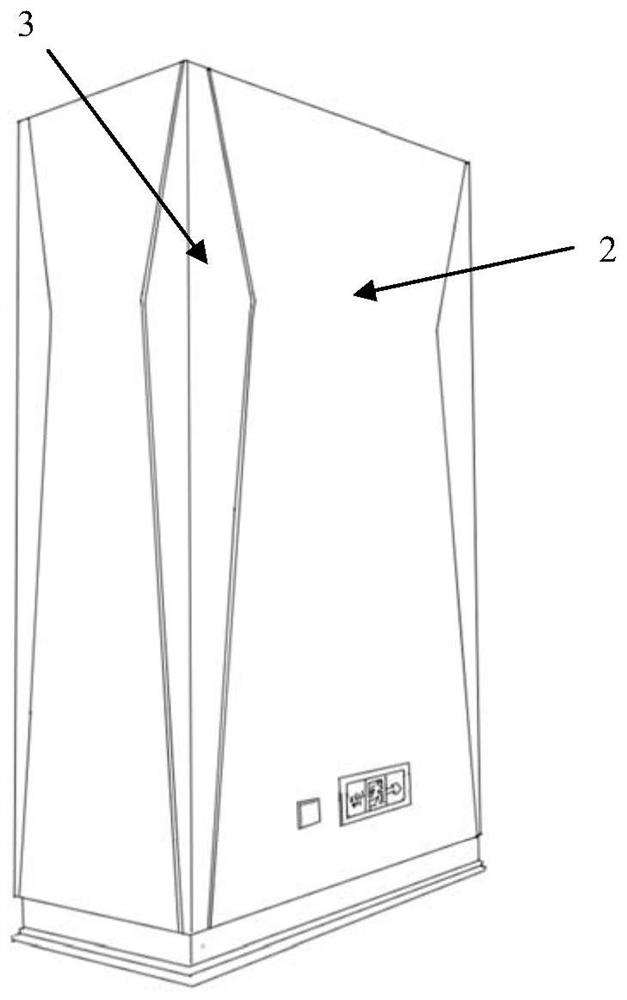

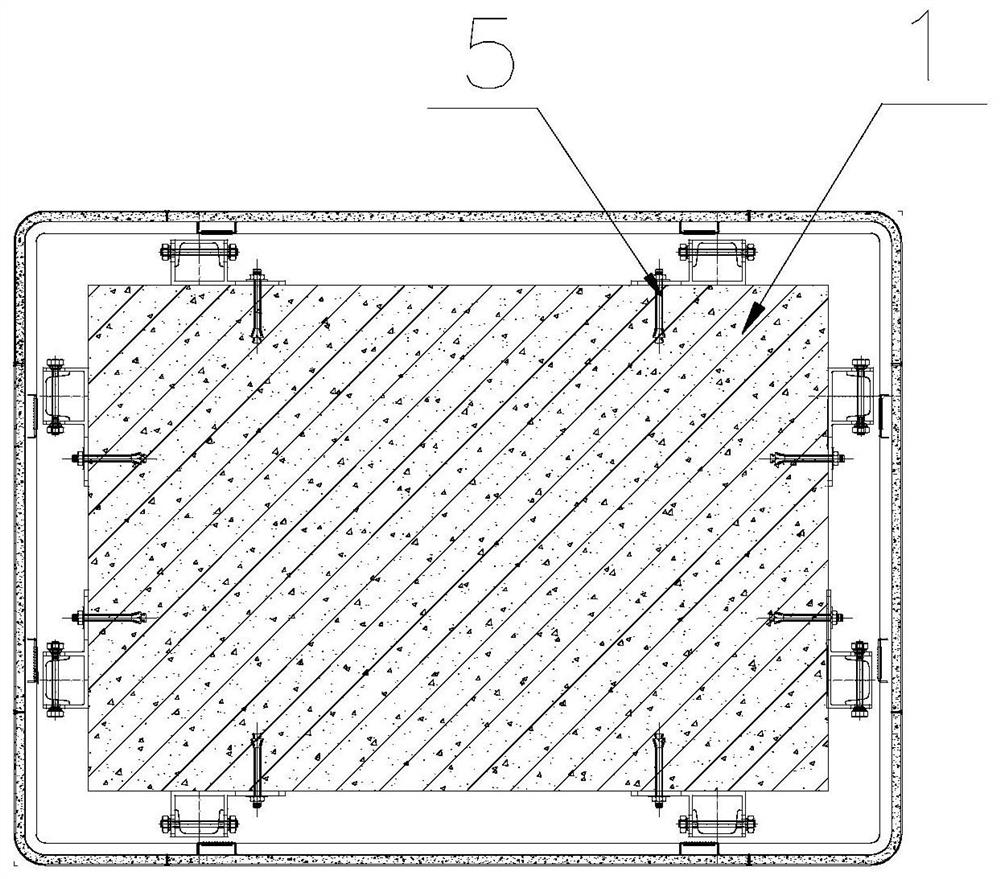

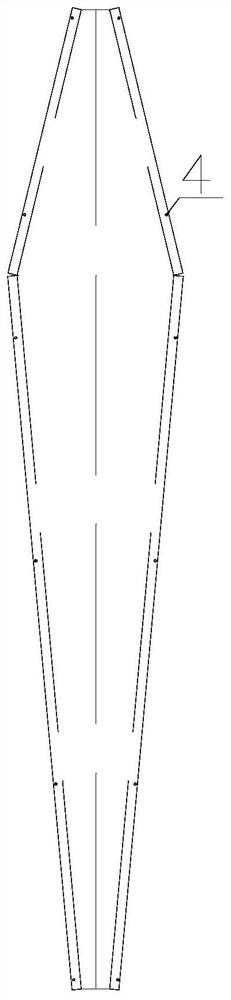

[0025] The first specific embodiment using the construction technology described in the present invention is a Hanque shaped column formed by splicing and installing irregular metal whole plates, such as figure 1 and image 3 As shown, the modeling column includes a structural column 1, a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com