Front vacuum filter

A filter and vacuum technology, applied in the fields of dispersed particle filtration, combined devices, chemical instruments and methods, etc., can solve the problem of carrying a small amount of droplets, and achieve the effect of reducing the number of droplets and reducing the filtration intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

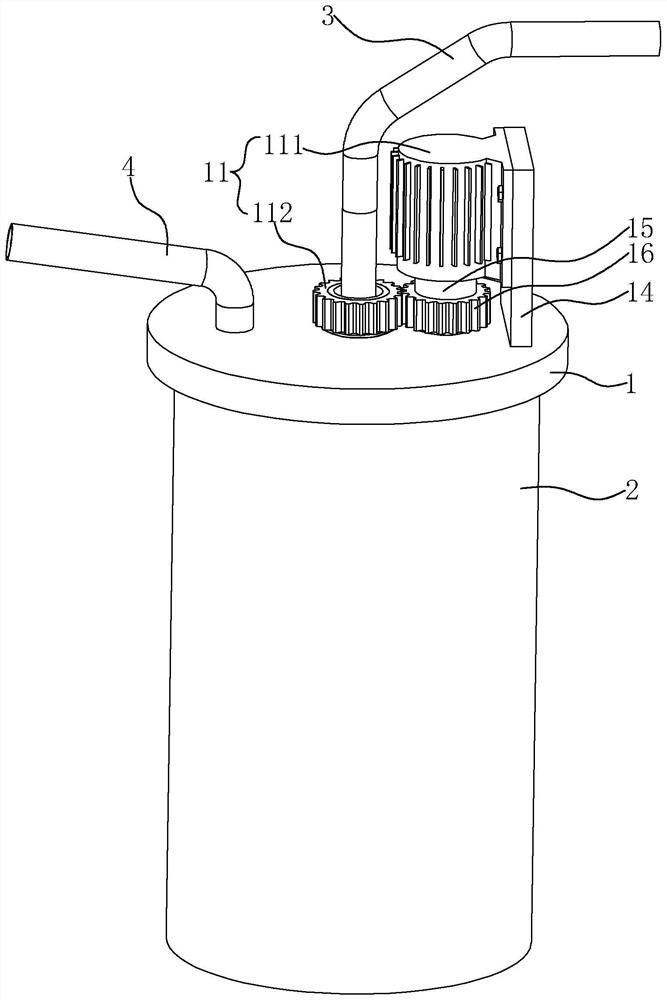

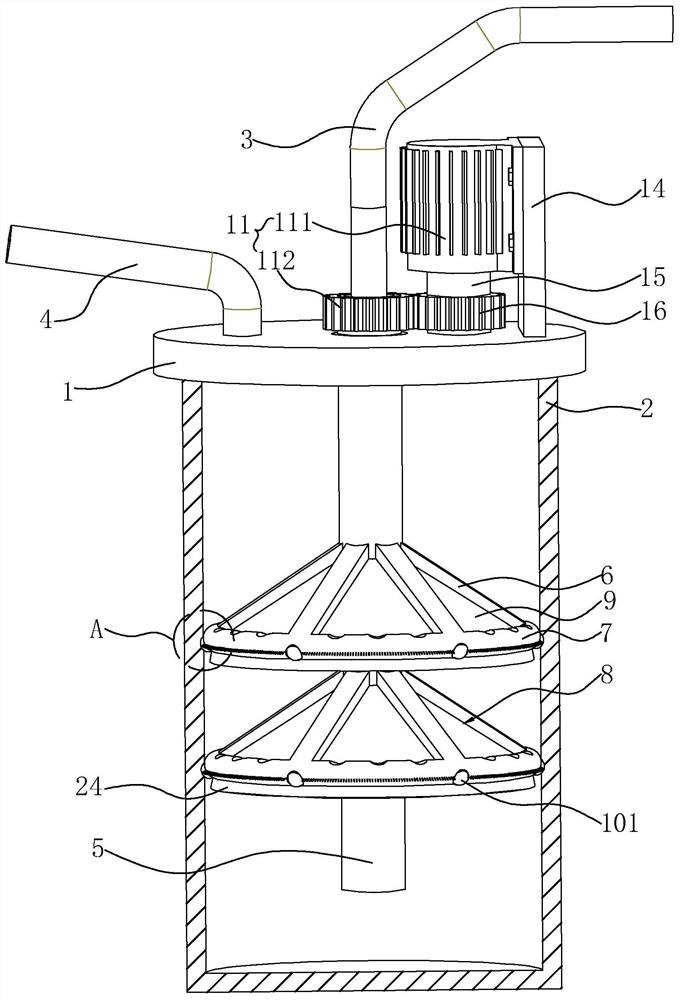

[0035] The following is attached Figure 1-7 The application is described in further detail.

[0036] A pre-vacuum filter disclosed in the embodiment of the present application, see figure 1 , The pre-vacuum filter includes a cover body 1 and a bottle body 2 of a collection bottle. The cover body 1 is a disc-shaped structure, the bottom of the cover body 1 near the edge is provided with a thread groove extending in the circumferential direction, the bottle body 2 is a hollow cylindrical structure, and the cover body 1 is screwed to the top of the bottle body 2 through the thread groove .

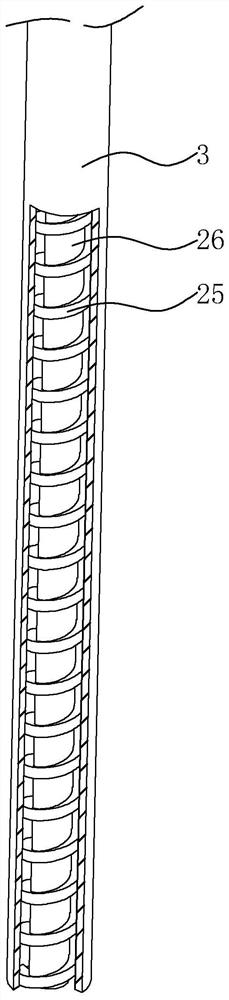

[0037] see figure 1 , The middle part of the cover body 1 is pierced with an air inlet pipe 3, and the air inlet pipe 3 extends into the bottle body 2 for passing in gas. The cover body 1 is pierced with an air outlet pipe 4 near the edge. The air outlet pipe 4 does not extend into the bottle body 2. The cover body 1 is provided with an air outlet hole. The air outlet hole communicates w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com