Automobile windscreen wiper

A wiper and automobile technology, which is applied in vehicle maintenance, vehicle cleaning, transportation and packaging, etc. It can solve problems such as easy accumulation of dust, incomplete meshing of rack bars and gears, and impact on service life, so as to achieve convenient adjustment and adjustment , to prevent the effect of relative rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

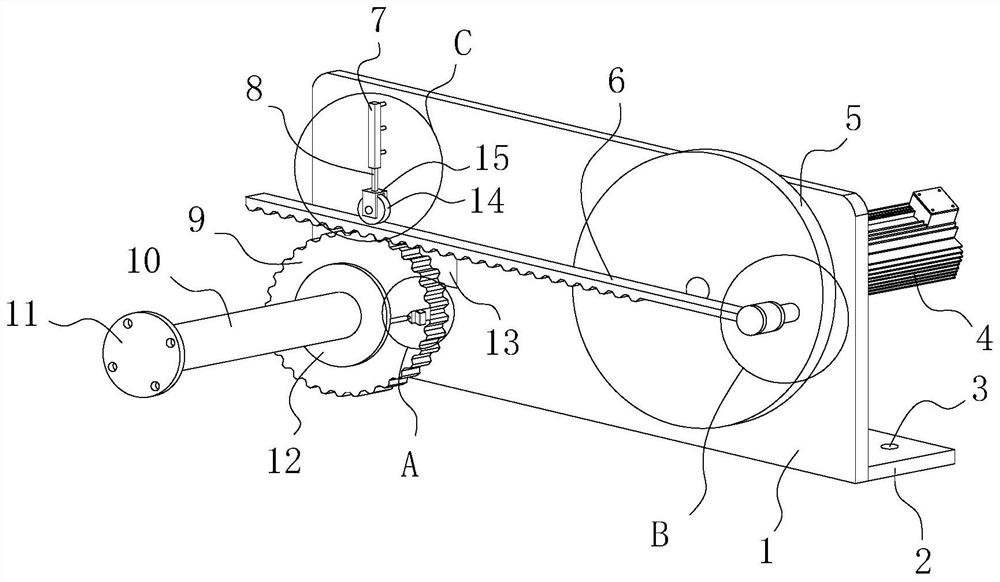

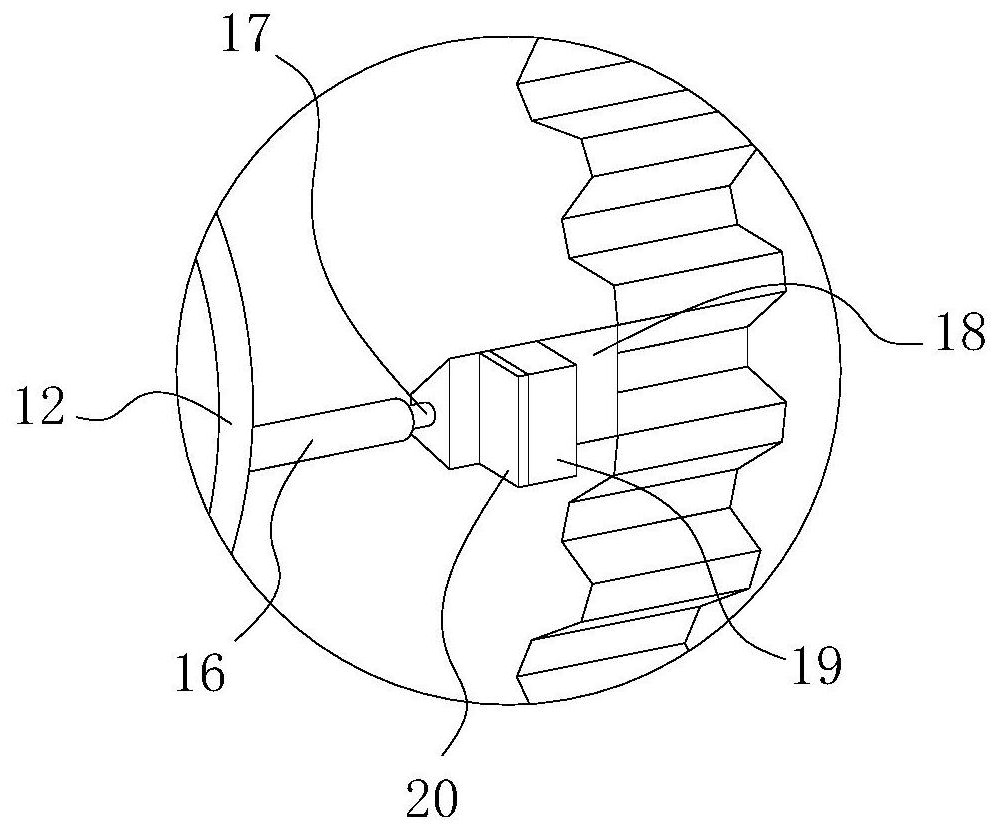

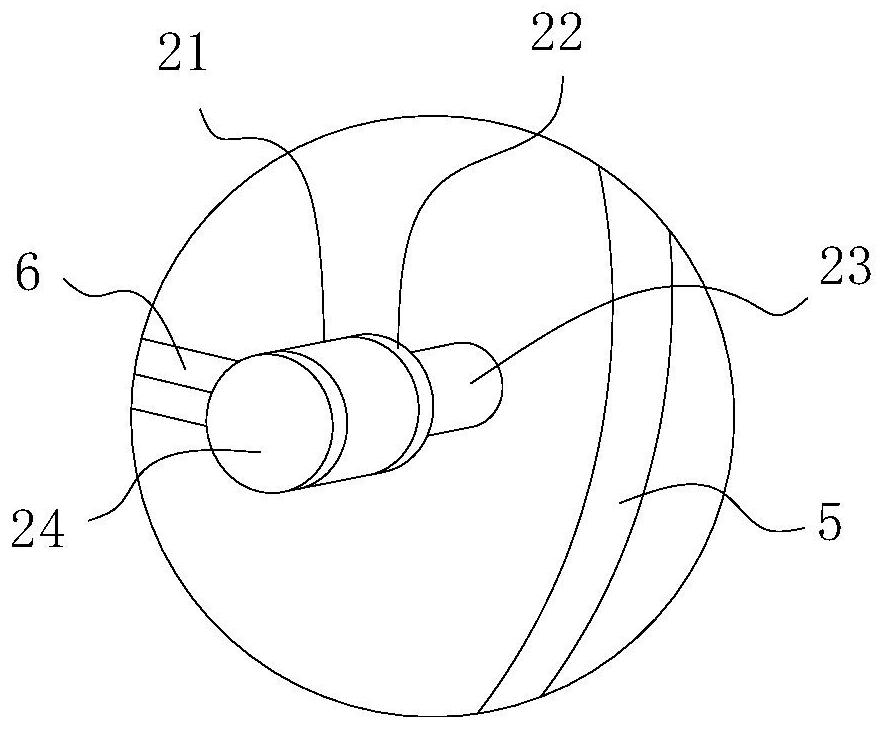

[0043] Specific implementation method: when the drive disk 5 is driven by the drive motor 4 to rotate, the drive disk 5 drives the rack bar 6 to reciprocate, and then the rack bar 6 drives the gear 9 to switch between forward rotation and reverse rotation. During the rotation of the gear 9 The wiper arm 10 drives the support plate 12 to rotate, and then the support plate 12 drives the push block 18 to rotate together. When the push block 18 rotates to the position where the rack bar 6 meshes with the gear 9, the movable magnet 19 overlaps with the fixed magnet 13 , and then under the repulsive effect of the movable magnet 19 and the fixed magnet 13, the push block 18 breaks away from the tooth groove on the gear 9, and the return spring 32 is in a compressed state at this time, when the push block 18 moves away from the rack bar 6 and the gear 9 When the engaged position rotates, the movable magnet 19 and the fixed magnet 13 are staggered, and then under the action of the resil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com