Liquid rocket engine thermal test parameter setting method considering real gas effect

A real gas and liquid rocket technology, used in jet engine testing, gas turbine engine testing, etc., can solve problems such as insufficient consideration of the impact, and achieve the effect of accurate thermal test parameters and reduced test risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is further described in detail below by way of examples.

[0038] For the high-pressure turbine, the theoretical adiabatic work deviation of the turbine based on the ideal gas reaches 10%-20%. This will lead to the deviation of the turbine power, which in turn will lead to the deviation of the static parameter balance of the liquid rocket engine, which will cause the excessive deviation of the turbo pump speed and the turbine outlet temperature, resulting in the excessive deviation between the experimental data and the theoretical setting working condition parameters.

[0039] For this reason, the following embodiments fully consider the influence of the real gas effect on the turbine power, and the calculation of the turbine power based on the ideal gas is corrected.

[0040] Turbine power calculation method 1:

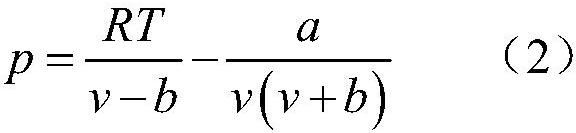

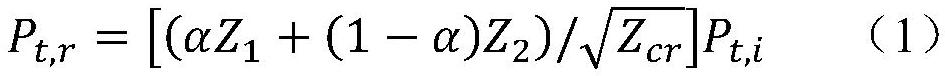

[0041] Based on the turbine power of the ideal gas, the influence of the real gas effect on the adiabatic work of the turbine is consid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com