Novel power electronic traction transformer topological structure and control method thereof

A technology of traction transformers and power electronics, which is applied in the direction of adjusting electrical variables, control/regulation systems, instruments, etc., and can solve problems such as high power and voltage levels, insignificant increase in power density of traction transformers, and design difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In the following, a new power electronic traction transformer topology and its control method will be described in detail in combination with Figures 1-6. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

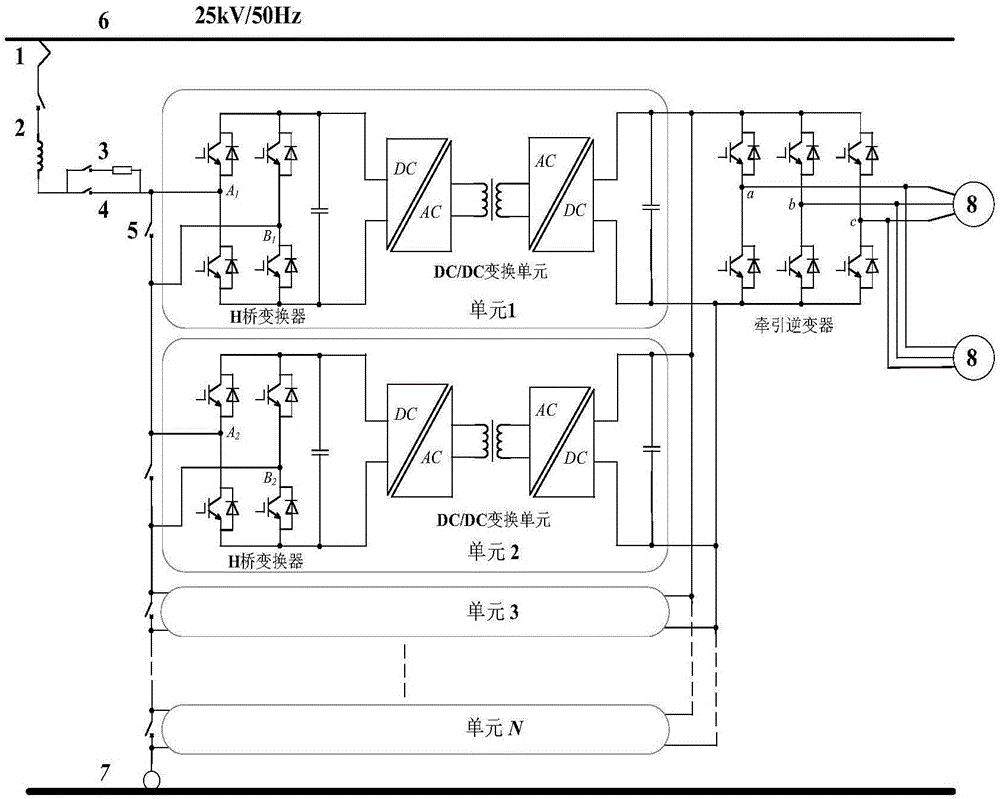

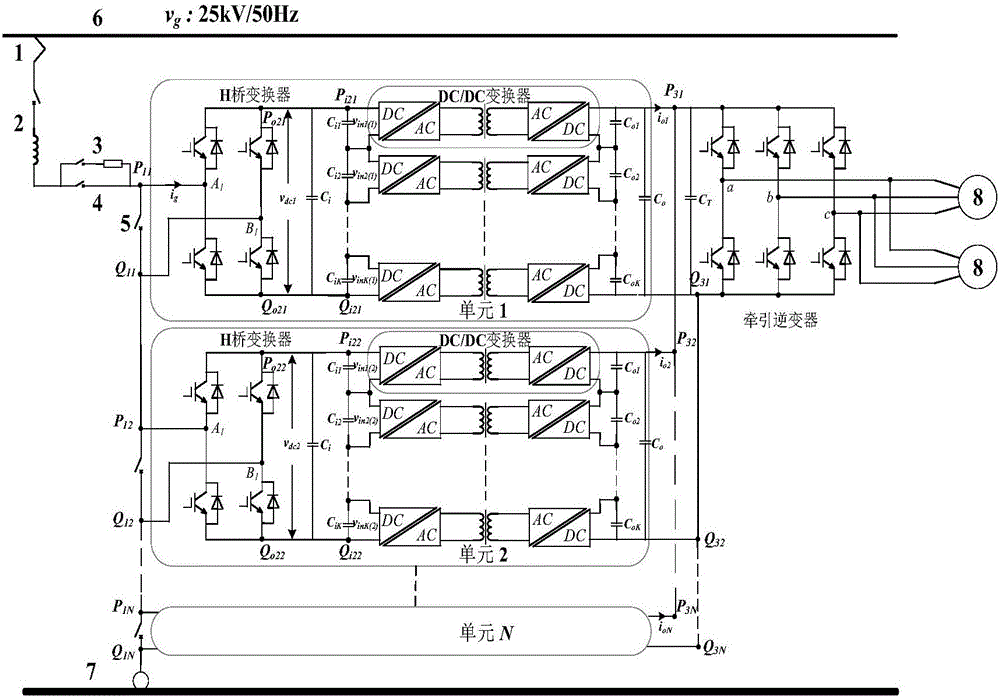

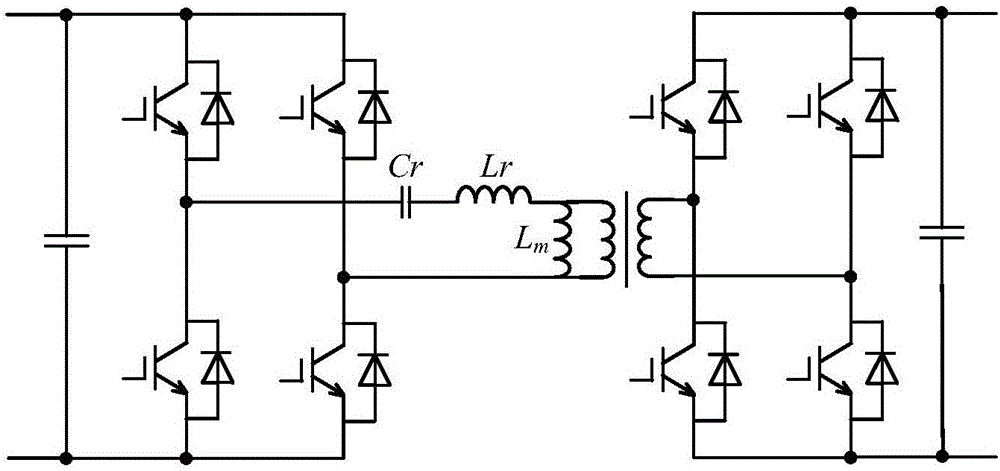

[0042] A new power electronic traction transformer topology, including N power conversion units; the power conversion unit includes an H-bridge converter and a medium / high-frequency isolated DC / DC conversion unit; the N H-bridge converters form N A cascaded H-bridge converter; the medium / high frequency isolated DC / DC conversion unit includes K DC / DC converters;

[0043] The input ends of the N power conversion units are connected in series, and the output ends are connected in parallel; the input ends of the N-level cascaded H-bridge converters are connected in series, and the output ends are not connected to each other; the N DC / DC conversion units The input ends are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com