High-toughness and high-rigidity ABS composite material special for storage battery shell, preparation method and application thereof

A composite material and storage battery technology, applied in the field of engineering plastics, can solve the problems of high toughness and high rigidity, and achieve the effect of high toughness and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

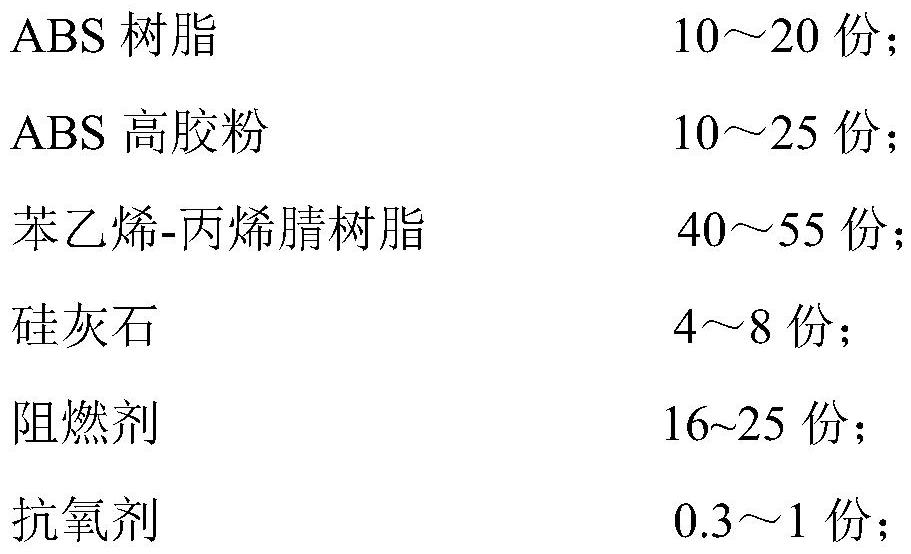

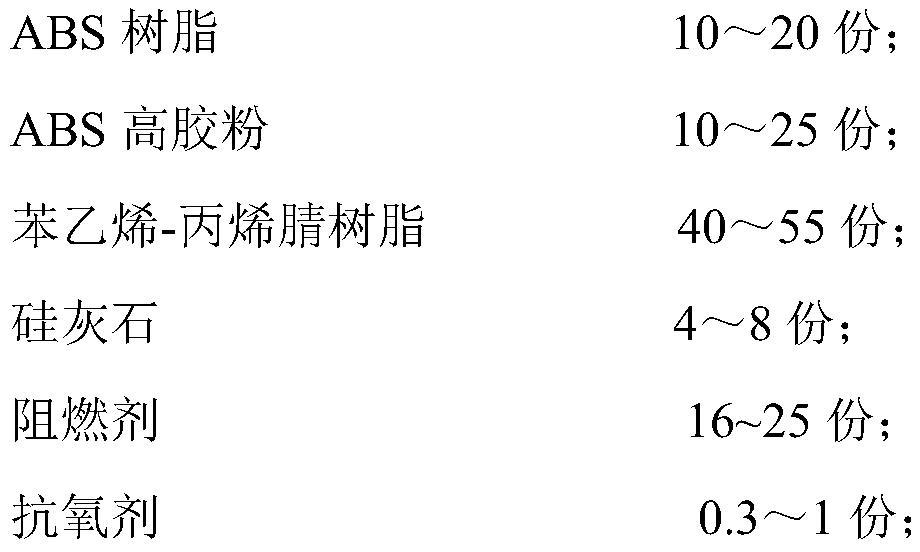

Method used

Image

Examples

Embodiment 1~3

[0059] This example provides a series of high-toughness and high-rigidity ABS composite materials. The content of ABS high-grade rubber powder used in different embodiments is different. The specific formula is shown in Table 1, so as to explore the influence of different ABS high-grade rubber powder content on the performance of composite materials.

[0060] The formula (part) of table 1 embodiment 1~3 composite material

[0061] Example 1 Example 2 Example 3 ABS resin 16 16 16 ABS high rubber powder A 10 15 25 Styrene-acrylonitrile resin A 40 40 40 Fibrous wollastonite B 6 6 6 Chlorinated polyethylene 3 3 3 brominated flame retardant 14 14 14 Antimony Flame Retardant 3 3 3 antioxidant 0.3 0.3 0.3

Embodiment 4~6

[0063] This embodiment provides a series of high-toughness and high-rigidity ABS composite materials. The content of styrene-acrylonitrile resin selected in different embodiments is different. The specific formula is shown in Table 2 to explore the effect of different styrene-acrylonitrile resin content on the performance of composite materials. influences.

[0064] The formula (part) of table 2 embodiment 4~6 composite material

[0065] Example 4 Example 5 Example 6 ABS resin 16 16 16 ABS high rubber powder A 15 15 15 Styrene-acrylonitrile resin A 45 50 55 Fibrous wollastonite B 6 6 6 Chlorinated polyethylene 3 3 3 brominated flame retardant 14 14 14 Antimony Flame Retardant 3 3 3 antioxidant 0.3 0.3 0.3

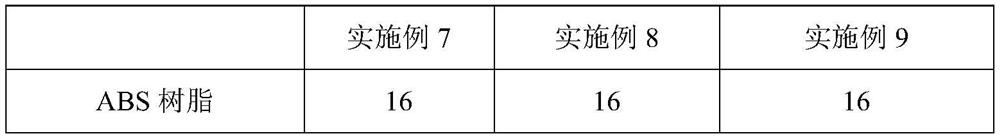

Embodiment 7~9

[0067] This example provides a series of high-toughness and high-rigidity ABS composite materials. The content of wollastonite used in different examples is different. The specific formula is shown in Table 3 to explore the influence of different wollastonite content on the performance of the composite material.

[0068] The formula (part) of table 3 embodiment 7~9 composite material

[0069]

[0070]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap