A semiconductor grade silicon single crystal furnace crucible lifting device and silicon single crystal furnace

A lifting device, silicon single crystal technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of pallet picking and placing, pollution, narrow gap, etc., and achieve low requirements, avoid touching the furnace wall, The effect of reducing occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

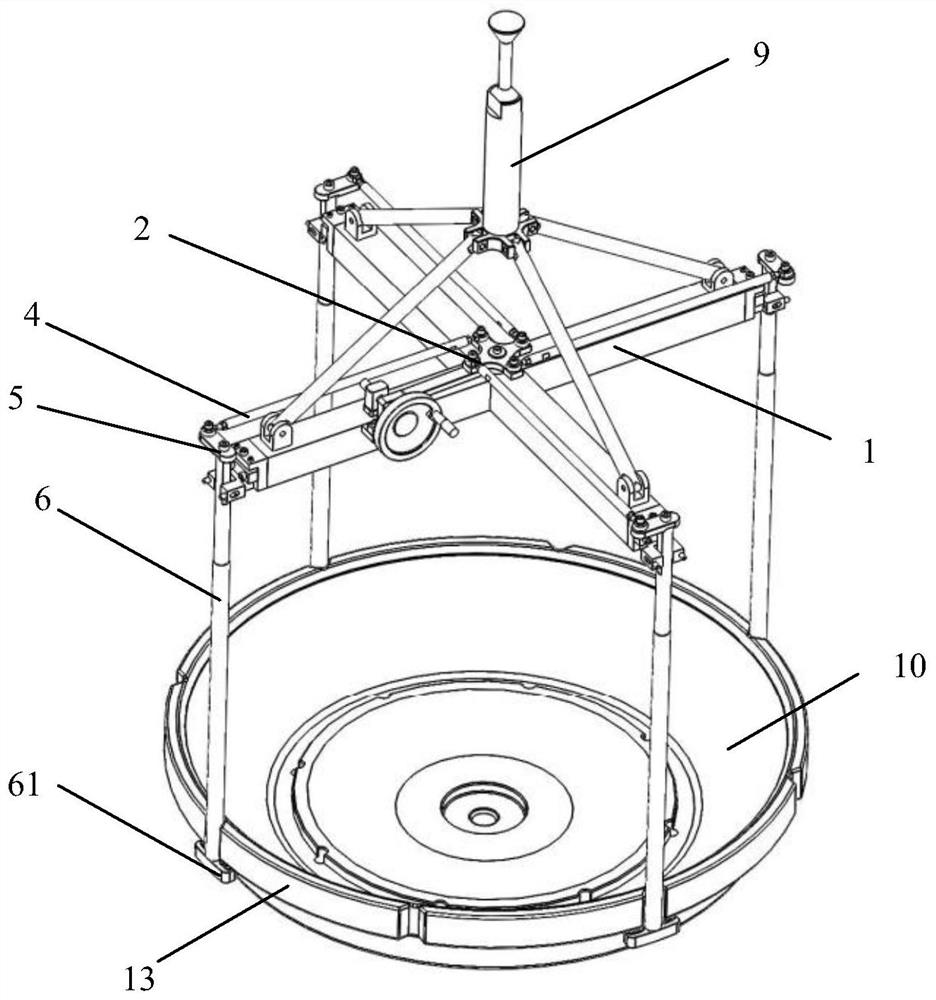

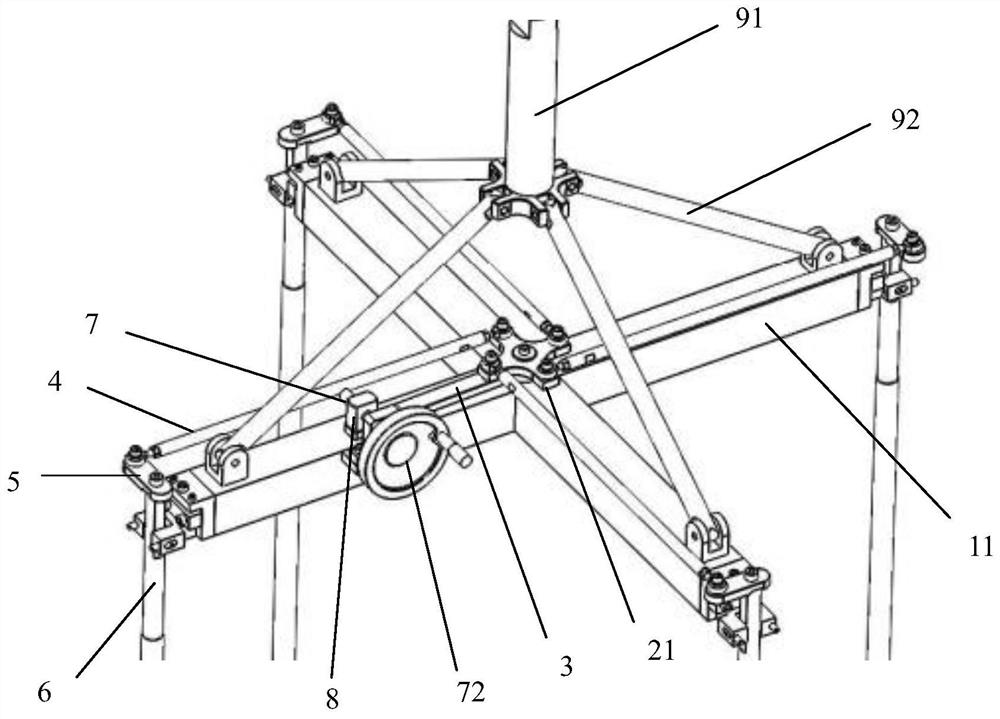

[0029] please combine Figure 2 to Figure 7 As shown in the figure, the present embodiment discloses a semiconductor-grade silicon single crystal furnace crucible lifting device, which includes a support 1, a cross turntable 2 on the support 1, a push rod 3 connected to the cross turntable 2, a plurality of first connecting rods 4, a plurality of The second connecting rod 5 , several third connecting rods 6 , the screw rod 7 , the sliding block 8 , and the hanger 9 .

[0030] The cross turntable 2 includes four rotating arms 21 extending outward from the middle position, and the four rotating arms 21 together form a "cross" shape. The middle position of the cross turntable 2 is hinged with the bracket 1 and can be rotated on the bracket 1 . The rear end of each first link 4 is hinged with the front end of a rotating arm 21 . The front end of each first link 4 is hinged with the rear end of one second link 5 . The front end of each second link 5 is hinged with the upper end ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap