A telecentric f-theta scanning lens processed by blue laser

A scanning lens, laser processing technology, applied in optics, optical components, instruments, etc., can solve the problems of difficult laser processing, low light absorption efficiency, uneven penetration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

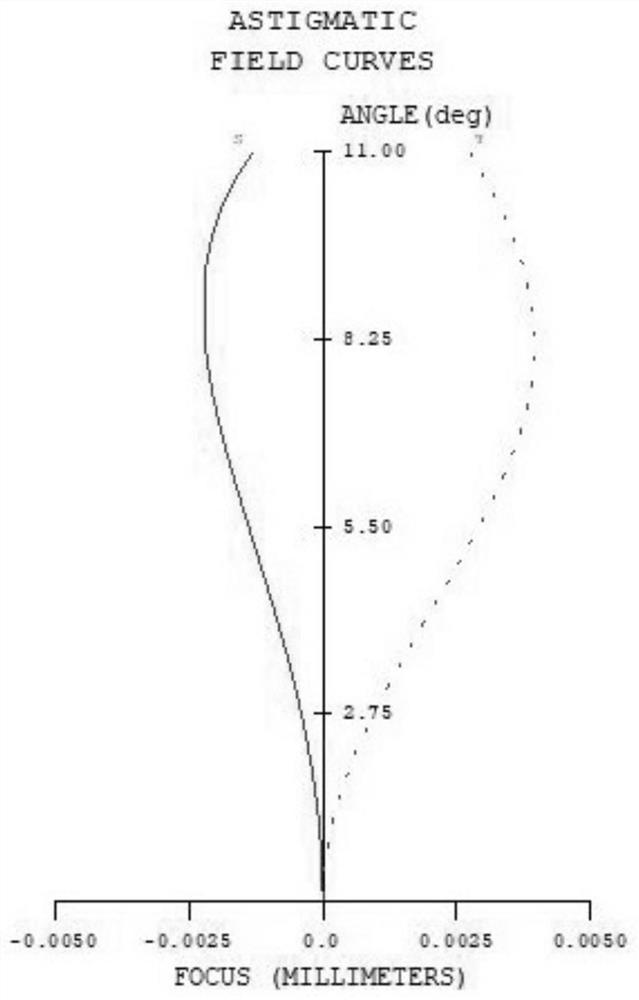

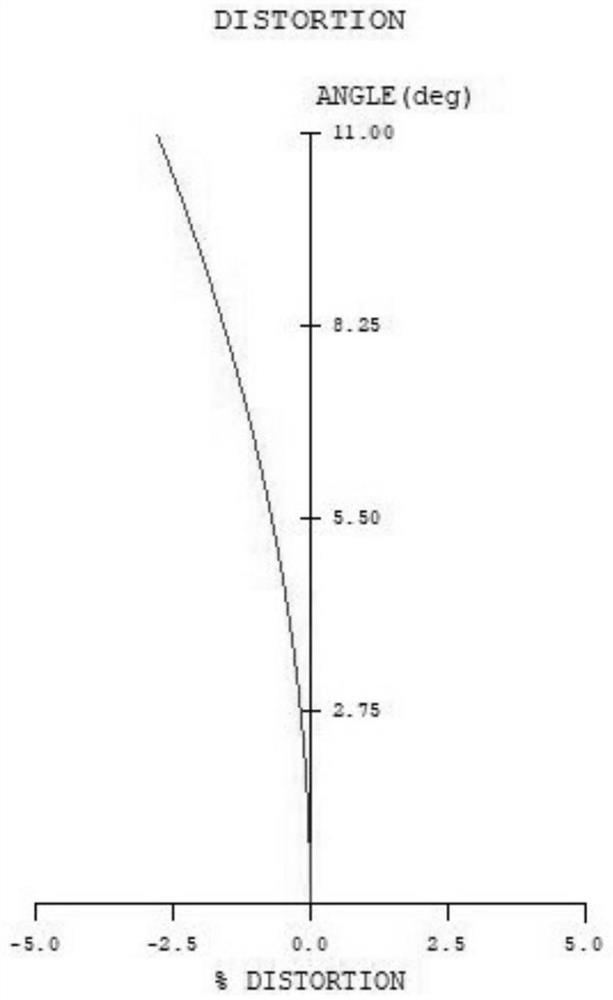

[0021] Embodiment The technical scheme and working principle of the present invention are illustrated by the core optical system of an F-Theta blue light 450nm telecentric scanning lens with a viewing angle of 11° and an entrance pupil diameter of 30mm. The embodiment has exactly the same structure as the summary of the invention, and to avoid repetition, only key data are listed.

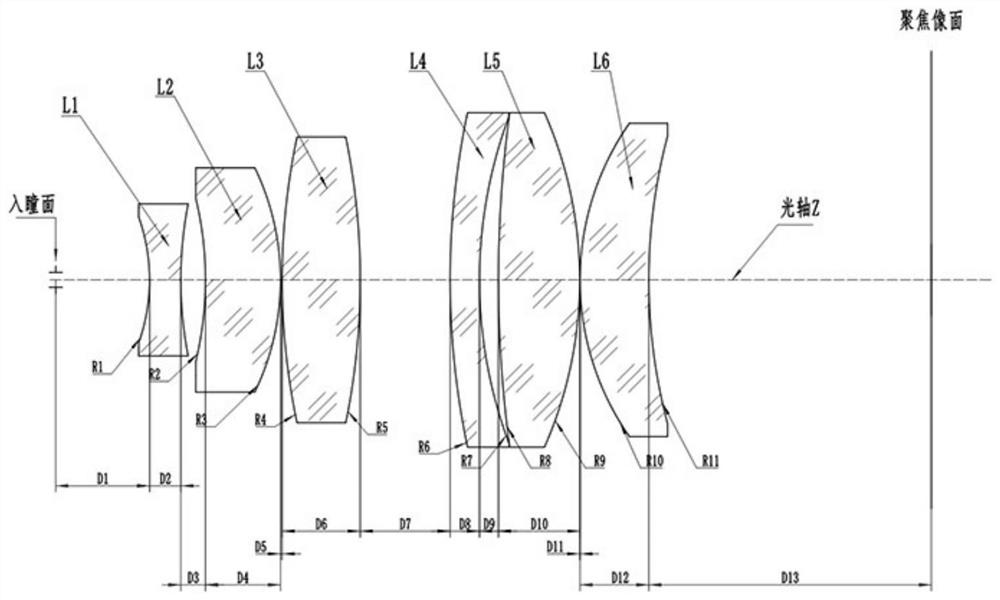

[0022] The schematic diagram of the optical system structure of the blue 450nm telecentric F-Theta scanning lens is as follows figure 1 As shown, in order to achieve the design target requirements, 6 optical glass lenses are used, and the lenses adopt the focal power distribution of "-++-++". Starting from the laser incident direction, it includes the first lens L1 with focal length f1, the second lens L2 with focal length f2, the third lens L3 with focal length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com