Rhizome crop harvester

A technology for crops and harvesters, which is applied in the direction of digging harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of reduced planting benefits of rhizomes, increased harvesting costs, and long operating cycles, so as to improve the overall operating effect. The effect of saving labor and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

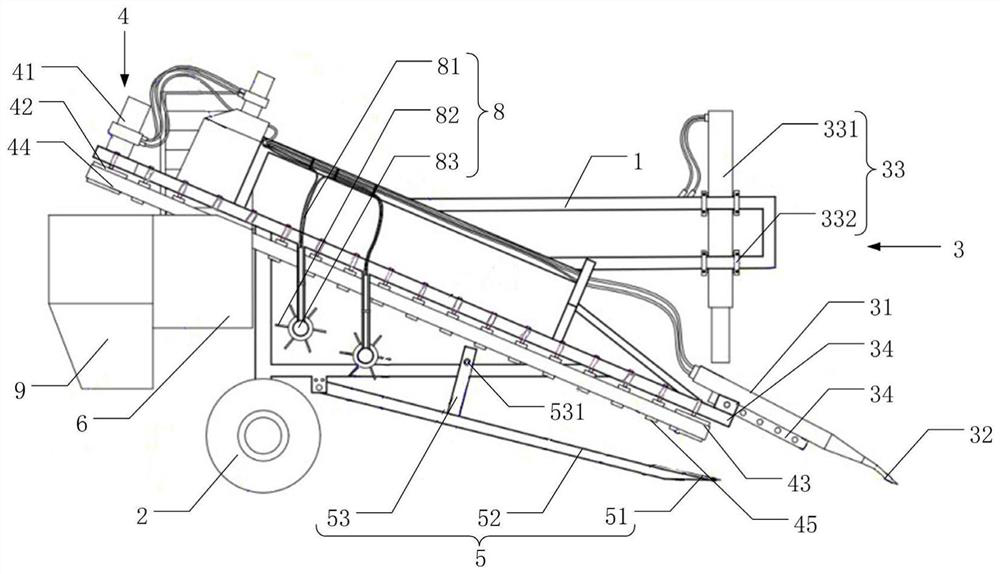

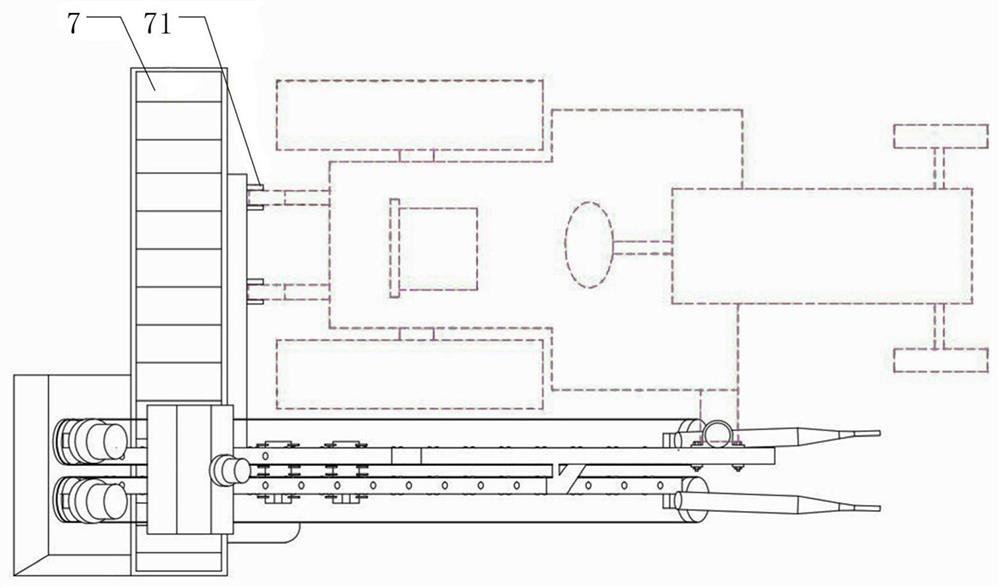

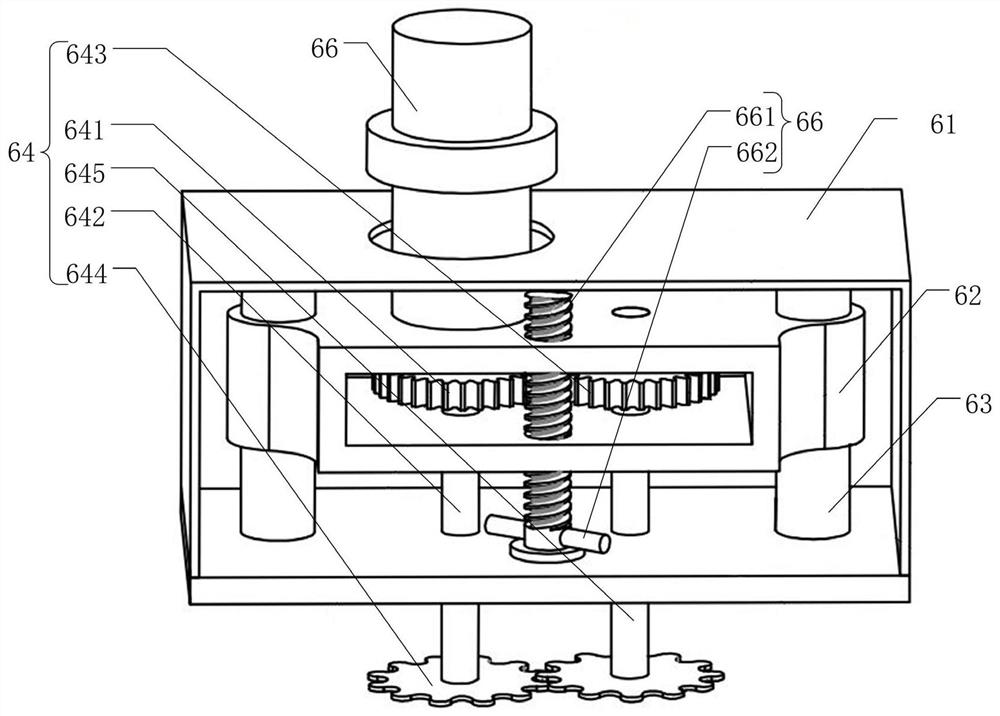

[0036]Example: CombinationFigure 1-3, A rhizome crop harfiner, including: rack 1, wheel 2, soil oscillate mechanism 3, starting mechanism 4, shovel mechanism 5, cutting mechanism 6, output mechanism 7, cleaning mechanism 8 and baffle 9 .

[0037]A wheel 2 is provided below the frame 1, and the soil oscillate mechanism 3 is mounted at the front portion of the frame 1, the shovel mechanism 5 is disposed in the middle of the frame 1, and the starting mechanism 4 is disposed above the machine 5 above the shovel. In the middle of the frame 1, the cleansing mechanism 6 and the output mechanism 7 are respectively disposed adjacent to the rear of the frame 1, and a baffle 9 is provided at the exit port of the cleansing mechanism 6, and the cleaning mechanism 8 is mounted in the soil oscillatage mechanism 3. The tilt support frame 35 rear, soil oscillatable mechanism 3, the starting mechanism 4, the shovel mechanism 5, the creation mechanism 6 and the output mechanism 7 are all controlled with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com