Clamp mechanism for safety belt suspension

A suspension mechanism and seat belt technology, applied in the direction of seat belts, life-saving equipment, etc., can solve problems such as difficulty in adapting to use requirements, inconvenient adjustment, etc., and achieve the effects of good reliability, convenient extension length, and tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

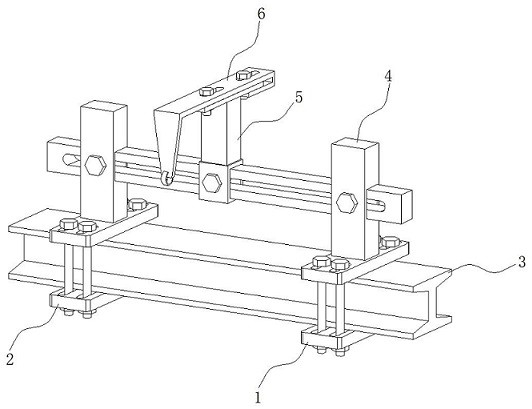

[0030] see figure 1 As shown, the present invention is a clamp mechanism for seat belt suspension, comprising a first fixing mechanism 1, a second fixing mechanism 2, a supporting mechanism 4, a moving mechanism 5 and a suspension mechanism 6, the first fixing mechanism 1 and the second fixing mechanism 2 are fixed side by side on the I-beam 3, a supporting mechanism 4 is fixed between the first fixing mechanism 1 and the second fixing mechanism 2, a moving mechanism 5 is fixed on the supporting mechanism 4, and a suspension mechanism 6 is fixed on the moving mechanism 5.

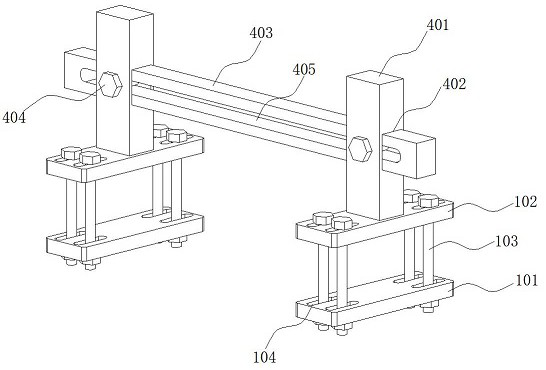

[0031] Among them such as figure 2 As shown, the first fixing mechanism 1 comprises a bottom fixing plate 101, a top fixing plate 102 and a first bolt 103, and the bottom fixing plate 101 and the top fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com