Hydro-bending die set for ultra-thin pipe with large diameter-thickness ratio and forming method

A technology of large diameter-thickness ratio and die set, which is applied in the field of hydraulic bending die set for large diameter-thickness ratio ultra-thin pipe, which can solve the problems of harsh hydraulic bending requirements, difficult control, and failure of press bending and forming, and achieve clamping and disassembly. Fast, simple and convenient, the sealing process is stable and reliable, and the effect of mass production is satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

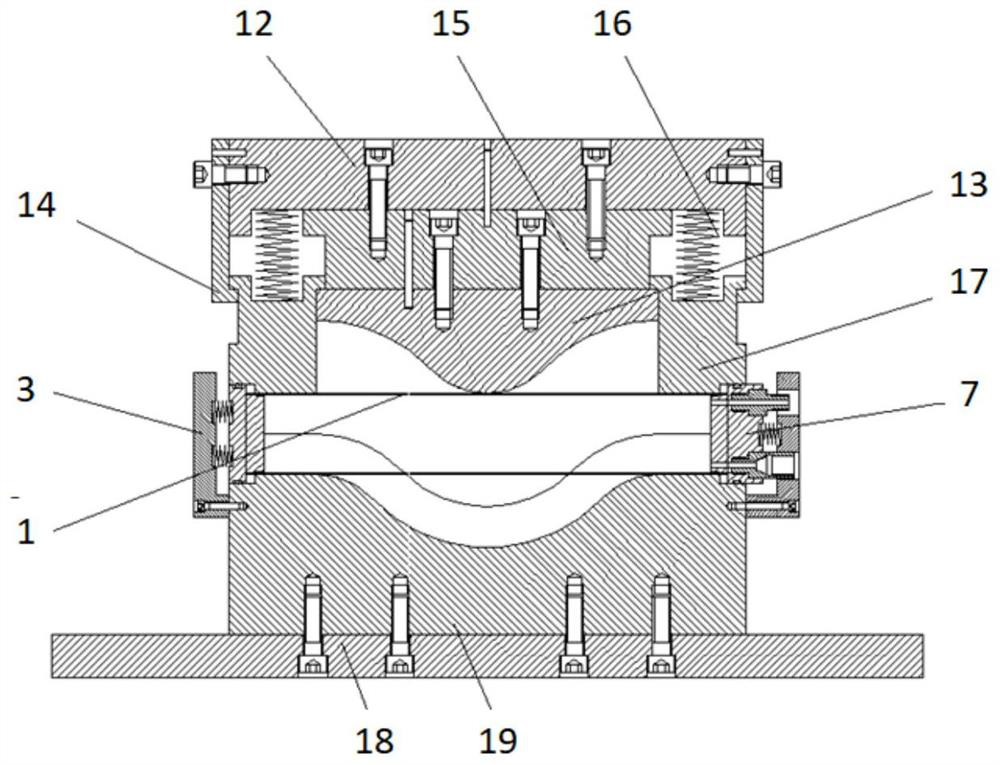

[0032] Such as figure 1 As shown, this embodiment provides a large-diameter-thick-ratio ultra-thin pipe filling hydraulic bending die set, including an upper die, a lower die, a left-end sealing mechanism, and a right-end sealing mechanism, and the pipe to be formed is arranged between the upper die and the lower die , the two ends of the upper mold are respectively provided with elastic edge-holding blocks 17, and the elastic edge-holding blocks 17 and the lower mold press against the end of the pipe from the upper and lower directions respectively;

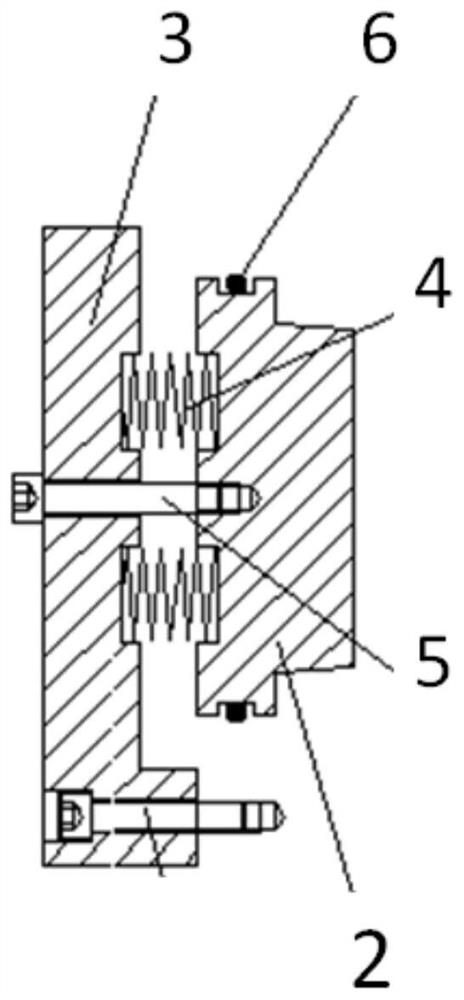

[0033] Such as figure 2 As shown, the left end sealing mechanism includes a left plug 2, a left block 3, a left spring 4, and a left guide pin 5, wherein one end of the left plug 2 is used as a sealing end to seal in the left port of the pipe, and the sealing end is connected to the inner wall of the pipe fitting 1. The left sealing ring 6 is arranged between them; the left sealing block 3 is set outside the left plug 2 and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com