Booster pump fastening and pipeline connecting structure of water purifier with double-cavity structure

A technology of booster pump and cavity structure, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sewage treatment equipment and other directions, can solve the problem that water purifiers are difficult to popularize more widely, and achieve a simple appearance and structure Beautiful appearance, simple structure setting and pipeline connection, simple and convenient fixing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

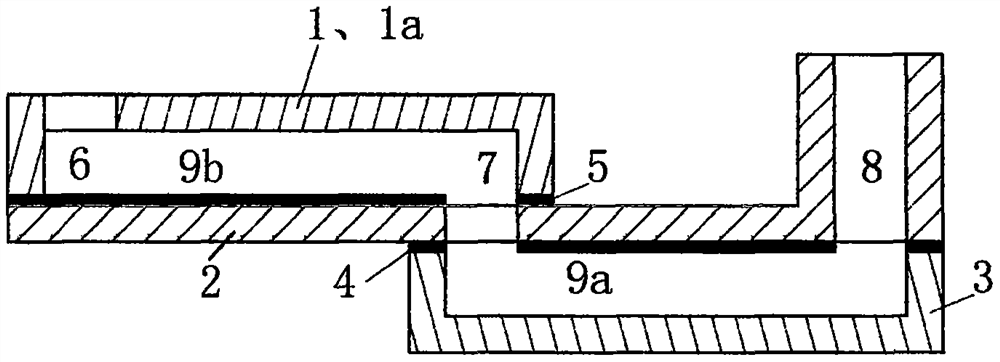

[0019] Example 1. A booster pump fastening and pipeline connection structure for a water purifier with a double-cavity structure, including a water-passing pipeline connected in series to multiple filters including a pre-filter and a reverse osmosis membrane filter, and a booster pump The part corresponding to the pre-filter is the pre-filter channel and the water inlet electric control valve is set. The water inlet and outlet pipes of the booster pump are respectively connected to the rear end of the pre-filter channel and the inlet of the reverse osmosis membrane filter. Water port; the reverse osmosis membrane filter gallbladder pure water port is connected to the pure water pipeline, the reverse osmosis membrane filter gallbladder drain outlet is connected to the concentrated water discharge pipeline of the concentrated water discharge flow control device, and is located at the concentrated discharge water discharge end of the concentrated water flow control device. In the...

Embodiment 2

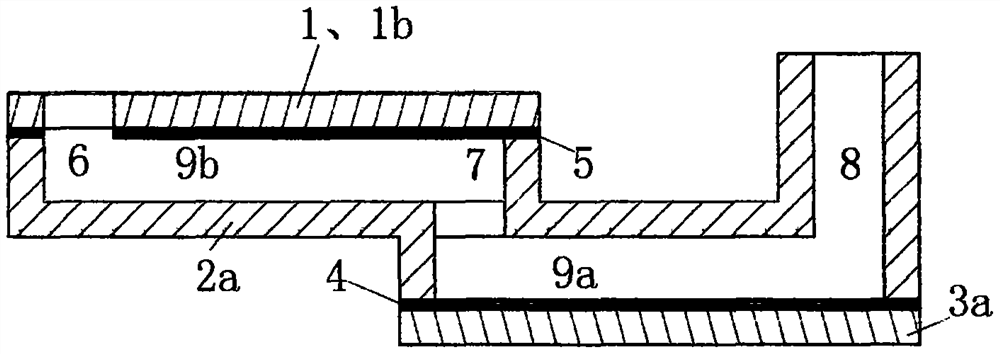

[0021] Example 2. On the basis of Example 1, the frame structure is provided with a downwardly extending screw support; one end is fixed on the lower end surface of the base of the gallbladder cavity by a screw, and the other end is horizontally extended and suspended in the double-layer U-shaped pipeline The structure is connected with the screw support by screws to form a whole.

[0022] As an improvement, the frame structure is provided with downwardly extending screw supports. The front end of the double-layer U-shaped pipe structure extending laterally and suspended in the air is connected with the screw support to form a whole through screws, so as to ensure that the intubation structure with the front end of the double-layer U-shaped pipe structure facing upward cooperates with the booster pump The plug-in fit of the relevant nozzle connection downward intubation structure has a stable working condition, and can withstand high water pressure in the pipe and is not affe...

Embodiment 3

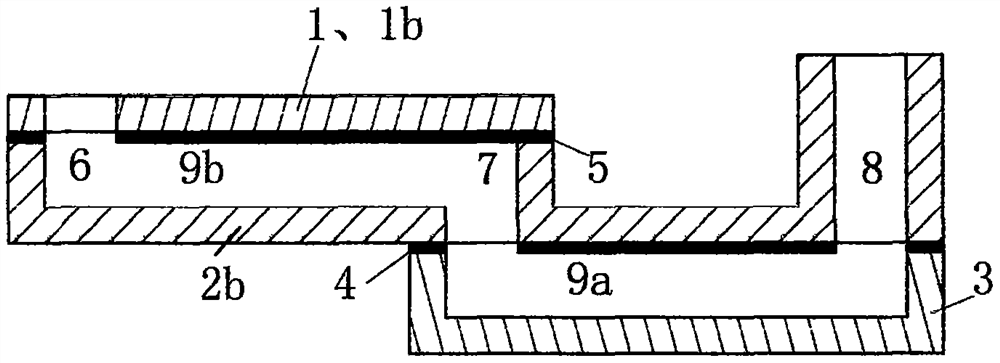

[0023] Example 3. A booster pump fastening and pipeline connection structure for a water purifier with a double-cavity structure, including a water-passing pipeline connected in series to multiple filters including a pre-filter and a reverse osmosis membrane filter, and a booster pump The part corresponding to the pre-filter is the pre-filter channel and the water inlet electric control valve is set. The water inlet and outlet pipes of the booster pump are respectively connected to the rear end of the pre-filter channel and the inlet of the reverse osmosis membrane filter. Water port; the reverse osmosis membrane filter gallbladder pure water port is connected to the pure water pipeline, the reverse osmosis membrane filter gallbladder drain outlet is connected to the concentrated water discharge pipeline of the concentrated water discharge flow control device, and is located at the concentrated discharge water discharge end of the concentrated water flow control device. In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com