Automated red date stone removing equipment

A technology for nuclear equipment and red dates, which is applied in the field of red dates pitting equipment, can solve the problems of high labor cost, complex structure of red dates pitting devices, low pitting efficiency, etc., and achieves the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

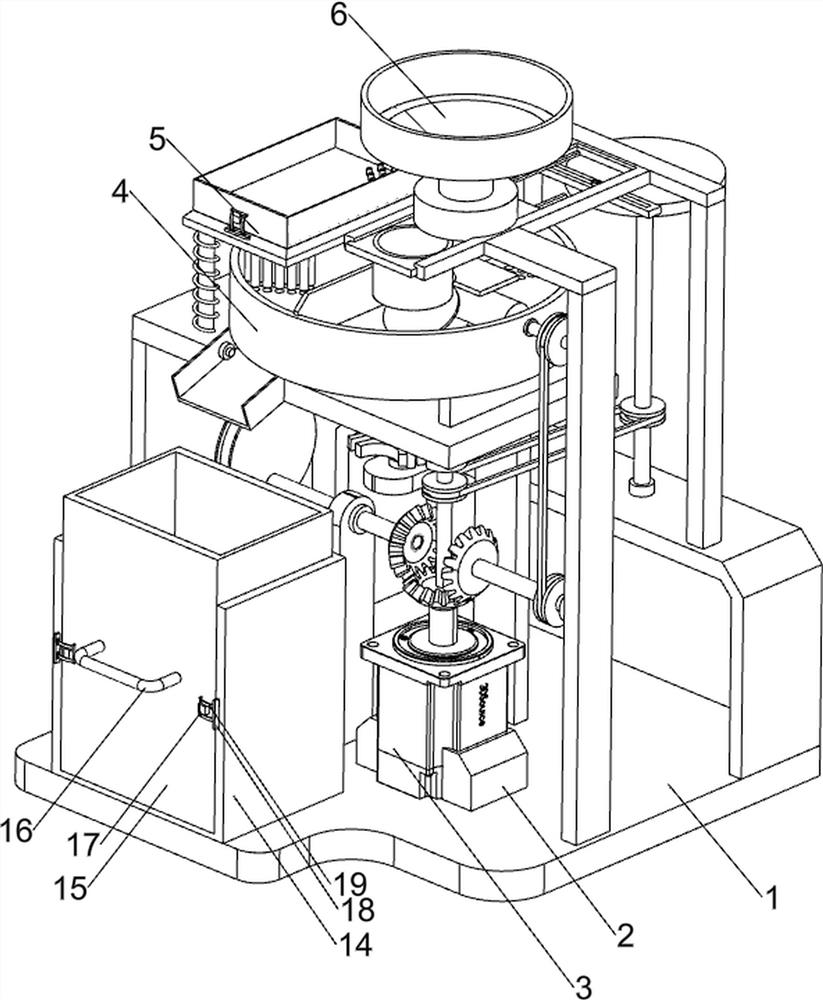

[0024] A kind of automation is used for jujube pitting equipment, such as figure 1 As shown, it includes a bottom plate 1, a fixed seat 2, a servo motor 3, a rotating mechanism 4, a nuclear removal mechanism 5, and a blanking mechanism 6. The bottom plate 1 is provided with a fixed seat 2 in the middle of the top, and the fixed seat 2 is provided with a servo motor 3. The top of the bottom plate 1 is provided with a turning mechanism 4, and a denucleating mechanism 5 is arranged between the turning mechanism 4 and the servo motor 3, and a feeding mechanism 6 is arranged on the right side of the top of the bottom plate 1.

[0025] The staff places the red dates in the feeding mechanism 6, and then starts the servo motor 3 to work, and the servo motor 3 drives the feeding mechanism 6 to discharge, so that the red dates are fed into the rotating mechanism 4, and the servo motor 3 drives the rotating mechanism 4 to work, Turning mechanism 4 drives jujube to rotate, and servo motor...

Embodiment 2

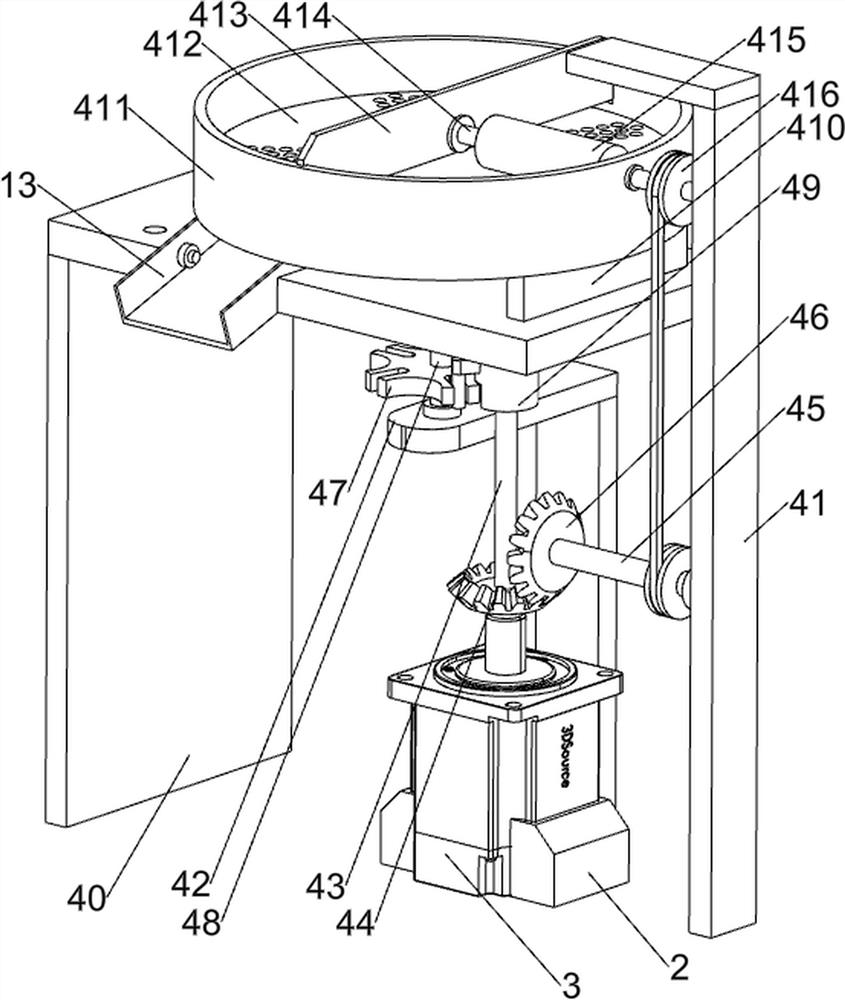

[0027] On the basis of Example 1, such as Figure 2-Figure 5As shown, the rotating mechanism 4 includes a first support frame 40, a second support frame 41, a third support frame 42, a first rotating shaft 43, a first bevel gear 44, a second rotating shaft 45, a second bevel gear 46, and a special-shaped turntable 47. The third rotating shaft 48, the convex circle 49, the support block 410, the placement plate 411, the clamping plate 412, the partition plate 413, the fourth rotating shaft 414, the roller 415 and the first pulley assembly 416; A support frame 40, a second support frame 41 is provided on the front side of the top of the base plate 1, a third support frame 42 is provided on the right part of the top of the base plate 1, a first rotating shaft 43 is connected to the output end of the servo motor 3, and a The first bevel gear 44, the second support frame 41 is rotatably connected with the second rotating shaft 45, the second rotating shaft 45 is connected with the ...

Embodiment 3

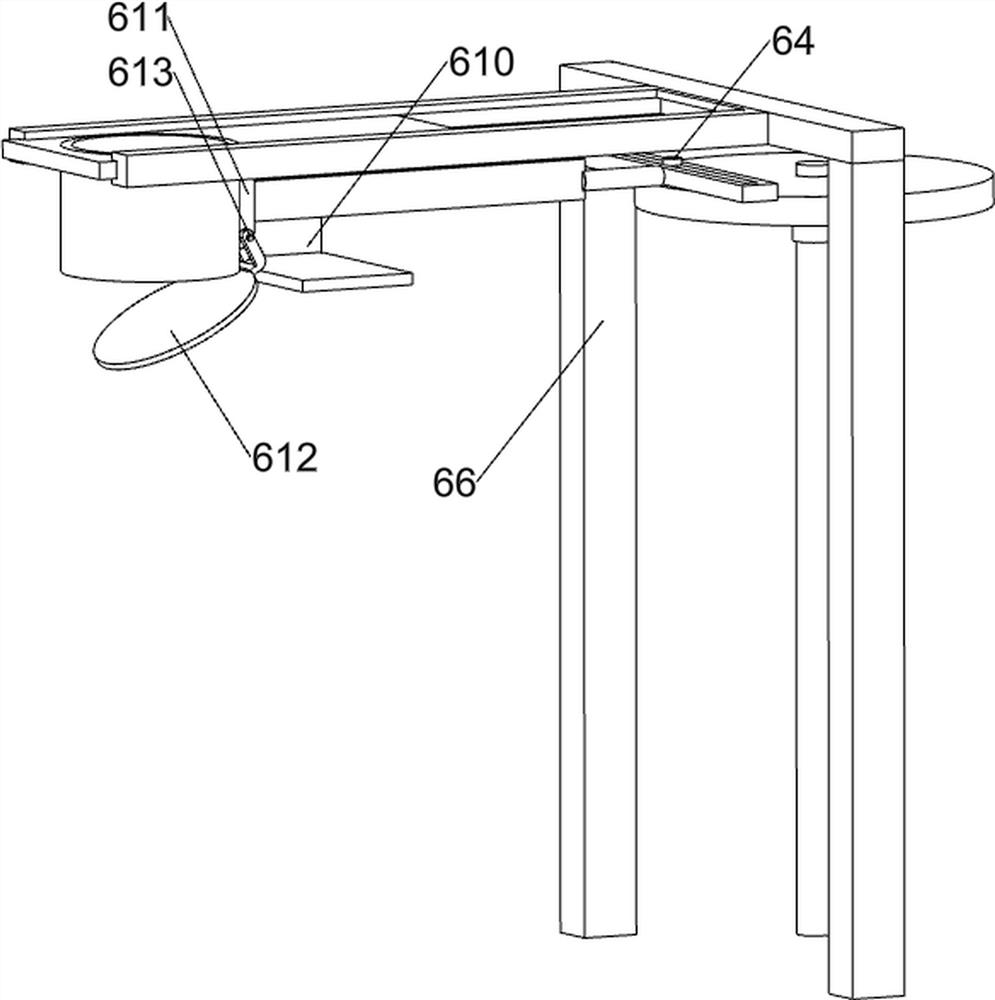

[0034] On the basis of Example 2, such as Figure 1-Figure 3 As shown, it also includes a first connecting block 7, a first buckle 8, a first clamping block 9 and a first storage basket 10, and the top of the first connecting plate 55 is connected with the first connecting block 7, and on the first connecting block 7 The first buckle 8 is rotatably connected, the first storage basket 10 is placed on the top of the first connecting plate 55, the nuclear tube 58 passes through the bottom of the first storage basket 10, and the first locking block is connected to the left side of the first storage basket 10 9. The first buckle 8 cooperates with the first block 9 .

[0035] The staff places the first storage basket 10 on the first connection block 7, makes the nuclear removal tube 58 pass through the bottom of the first storage basket 10, and then swings the first buckle 8 so that the first buckle 8 is aligned with the first locking block. 9 contacts, the first receiving basket 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com