Automatic jujube pitting equipment

A technology for nuclear equipment and jujubes, which is applied in the field of automatic jujube denucleating equipment, can solve the problems of low denucleating efficiency of jujubes, etc., and achieves the effect of efficient denucleation and easy collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

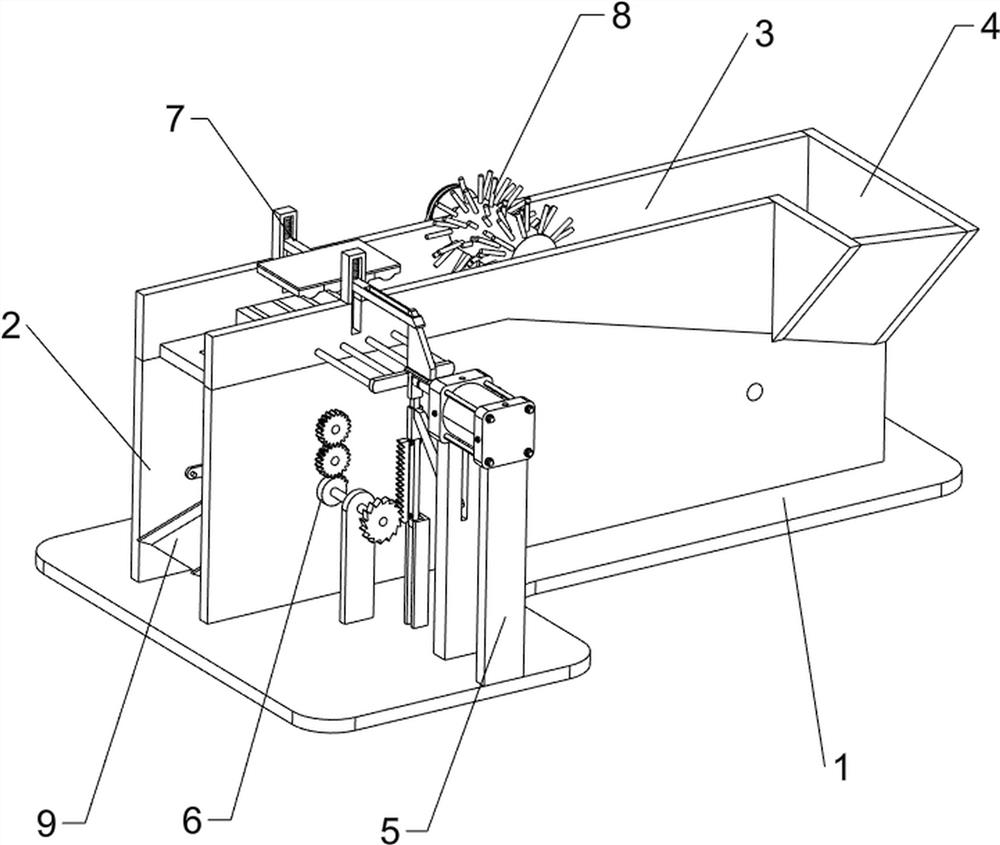

[0026] A kind of jujube automatic denuclearization equipment, such as figure 1 and figure 2 As shown, it includes a bottom plate 1, a support plate 2, a side baffle 3, a placement mechanism 4 and a nuclear removal mechanism 5. The bottom plate 1 is symmetrically provided with a support plate 2, and the support plate 2 is equipped with a side baffle 3, and the side baffle A placement mechanism 4 is provided between the plates 3 , and a coring mechanism 5 is provided on the base plate 1 .

[0027] When people need to use this device, first people place the dates in the placement mechanism 4, then they can start the pitting mechanism 5, and at the same time people fix the jujube machine, and then when the pitting mechanism 5 moves to contact with the dates, remove The nuclear mechanism 5 removes the core of the jujube. After the core removal is completed, people can take the date off after the core removal mechanism 5 is reset. This can be repeated continuously to realize the r...

Embodiment 2

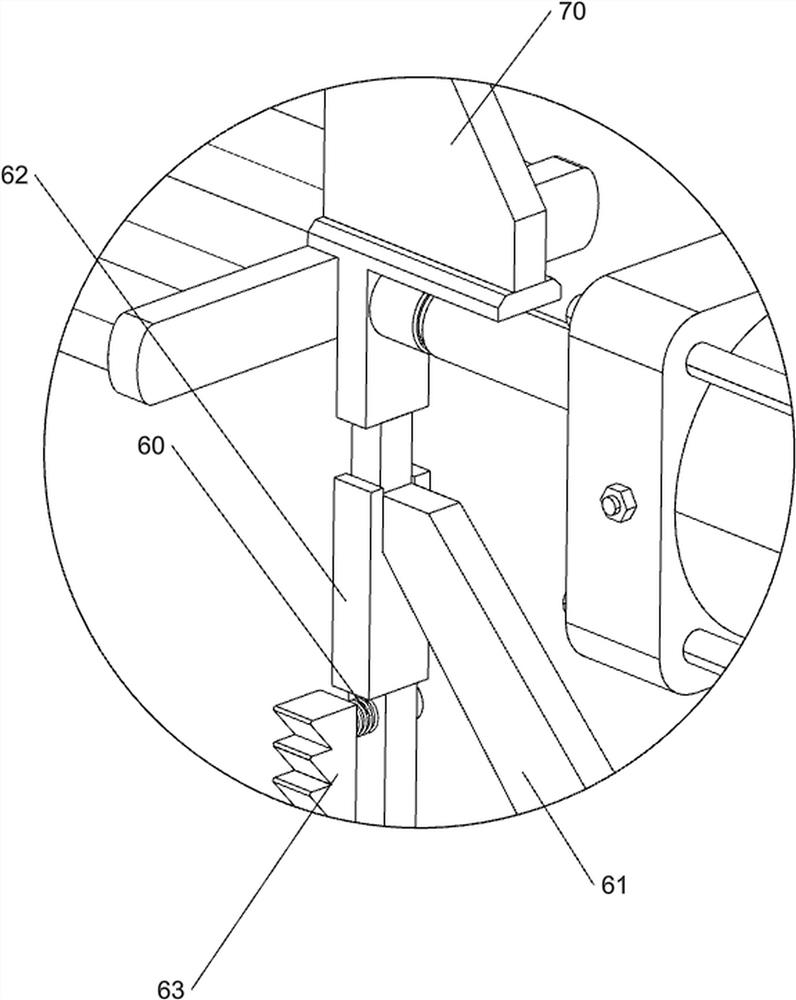

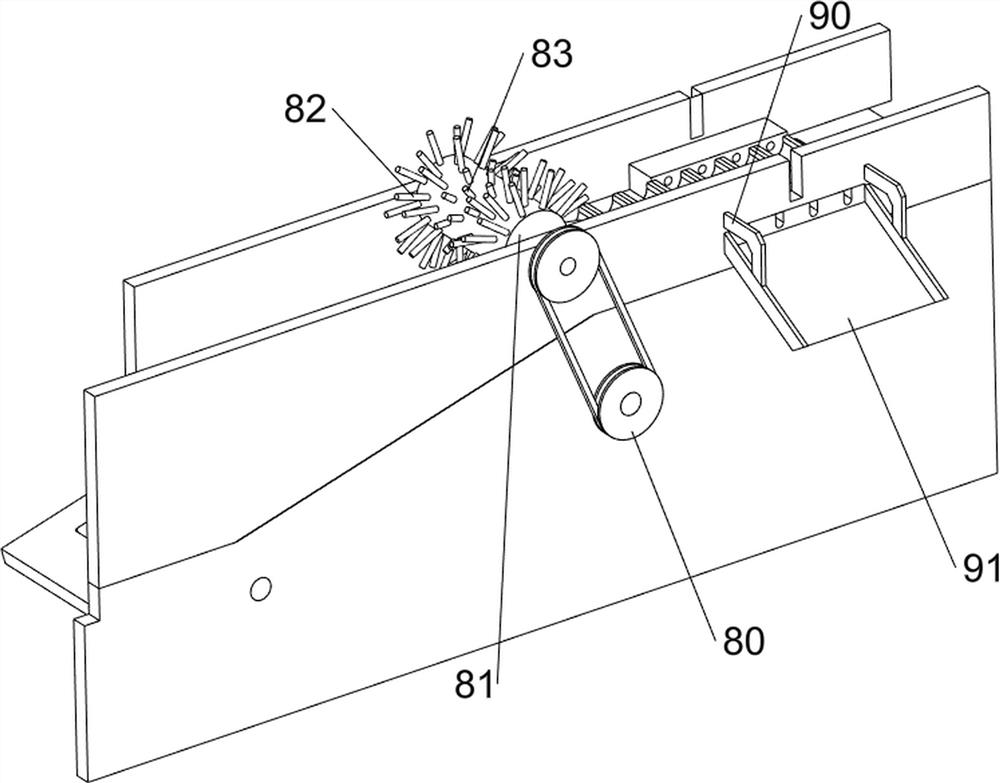

[0032] On the basis of Example 1, such as figure 1 , image 3 , Figure 4 and Figure 5 As shown, the transmission mechanism 6 is also included, and the transmission mechanism 6 includes an elastic member 60, a first wedge block 61, a special-shaped block 62, a ratchet rack 63, a guide bar 64, a first spring 65, a ratchet gear 66, and a missing gear. 67 and full gear 68, the push rod 51 is provided with the first wedge-shaped block 61, the front side of the bottom plate 1 top is provided with a guide bar 64, and the sliding type in the guide bar 64 is provided with a special-shaped block 62, and the sliding type on the special-shaped block 62 is provided with a spine The toothed rack 63, the elastic member 60 is arranged symmetrically between the ratchet toothed rack 63 and the special-shaped block 62, and the first spring 65 is connected between the special-shaped block 62 and the bottom plate 1, and the first spring 65 is positioned at the inner side of the guide bar 64, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com